Mitsubishi Montero (2002-2004). Manual - part 665

TSB Revision

DIAGNOSTIC TROUBLE CODE PROCEDURES

13Ac-357

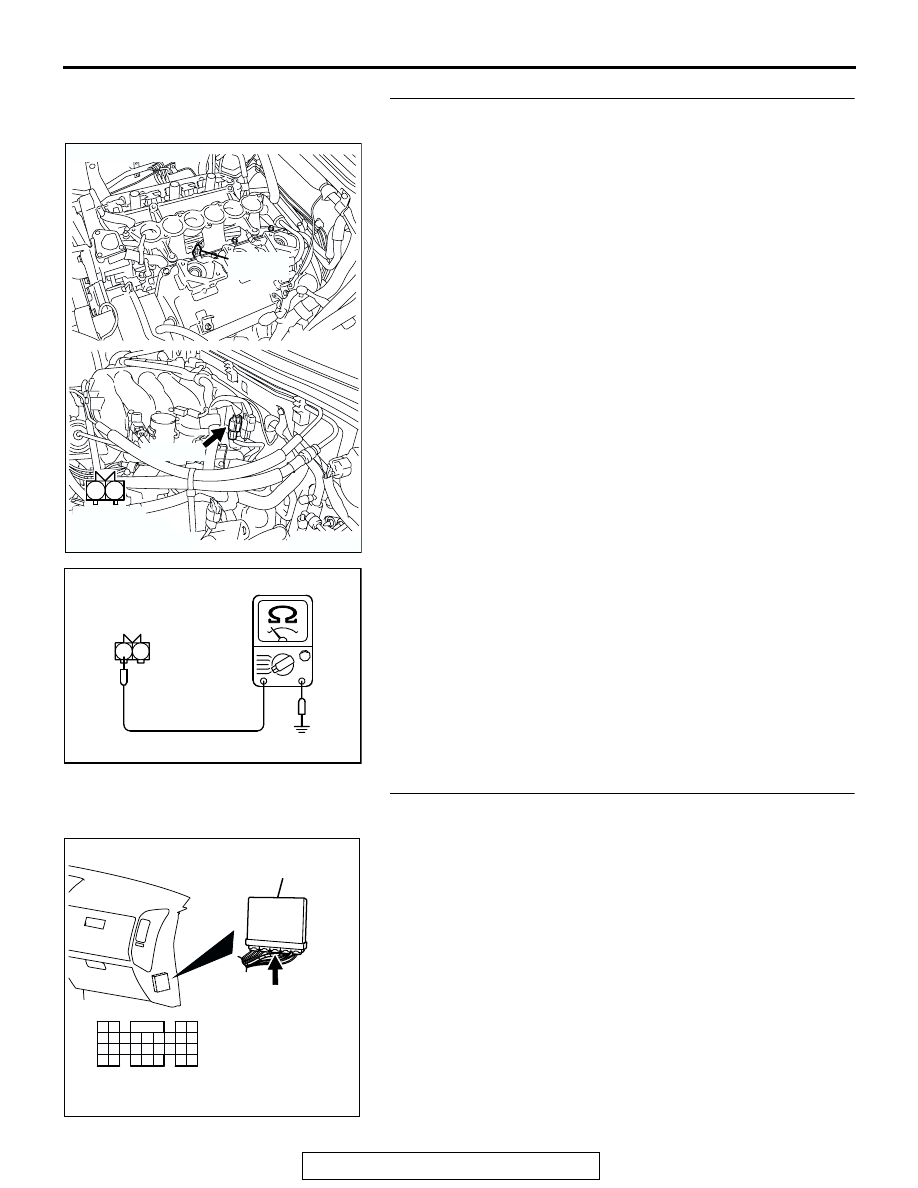

STEP 2. Check the continuity at knock sensor harness

side connector B-09.

(1) Disconnect the connector B-09 and measure at the harness

side.

(2) Check for the continuity between terminal No. 2 and

ground.

• Should be less than 2 ohms.

Q: Is the continuity normal?

YES : Go to Step 3.

NO : Repair an open circuit or harness damage between

knock sensor connector B-09 (terminal No. 2) and

ground. Then go to Step 6.

STEP 3. Check harness connector D-134 at PCM for

damage.

Q: Is the harness connector in good condition?

YES : Go to Step 4.

NO : Repair or replace it. Refer to GROUP 00E, Harness

Connector Inspection

. Then go to Step 6.

AK200961

1

2

CONNECTOR: B-09

B-09(GR)

KNOCK

SENSOR

AB

HARNESS

CONNECTOR:

COMPONENT SIDE

AKX01415AN

B-09 HARNESS

CONNECTOR:

COMPONENT SIDE

1

2

AK201166

61

62

63

64

65

66

67

68

69

70

71

76

77

78

79

85

86

87

80

72

73

74

75

81

82

83

84

88

89

CONNECTOR: D-134

AB

PCM

D-134(GR)

HARNESS CONNECTOR:

COMPONENT SIDE