Mitsubishi Montero (2002-2004). Manual - part 661

TSB Revision

DIAGNOSTIC TROUBLE CODE PROCEDURES

13Ac-341

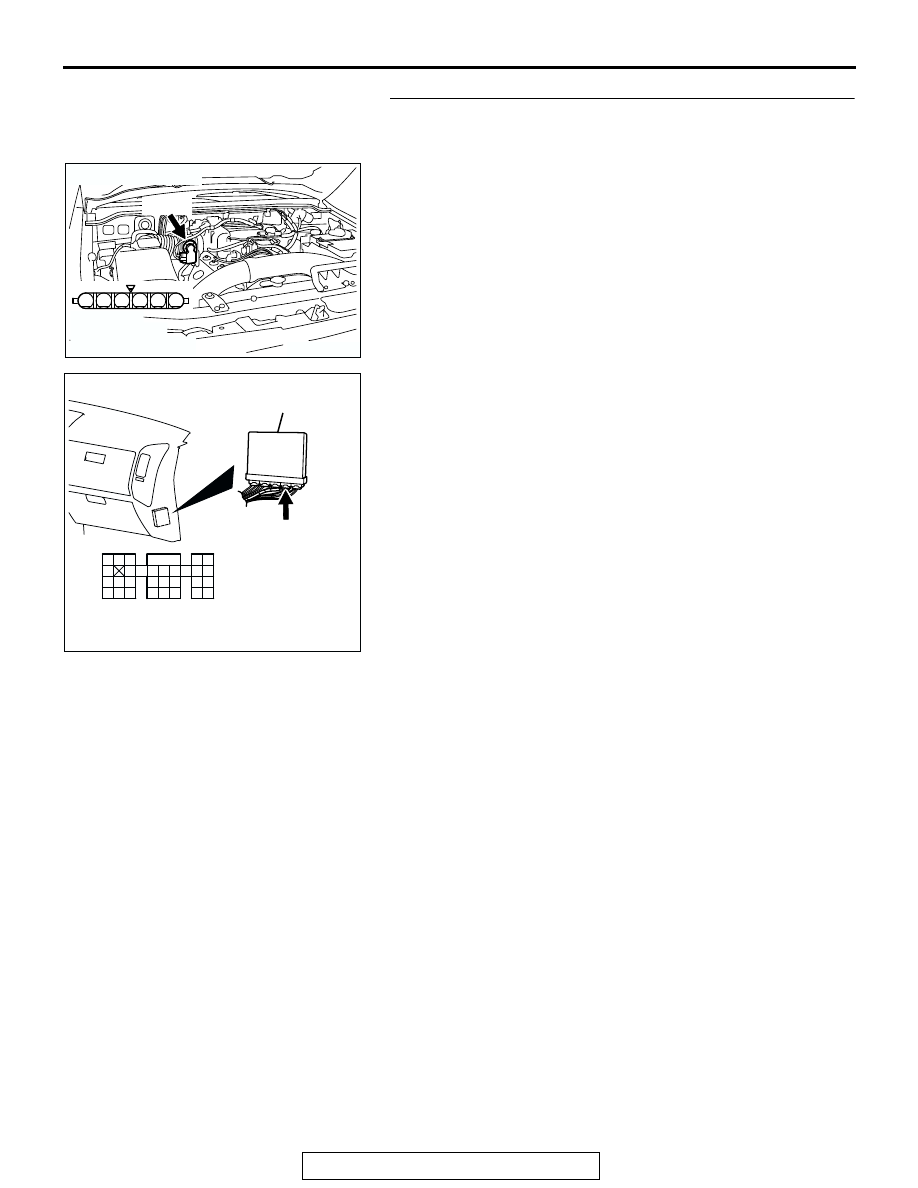

STEP 5. Check for open circuit and harness damage

between throttle position sensor connector B-05 (terminal

No. 4) and PCM connector D-135 (terminal No. 105).

Q: Is the harness wire in good condition?

YES : Go to Step 6.

NO : Repair it. Then go to Step 9.

AK201174

1

6 5 4 3 2

B-05(B)

CONNECTOR: B-05

HARNESS

CONNECTOR:

COMPONENT SIDE

AB

AK200947

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

CONNECTOR: D-135

HARNESS CONNECTOR:

COMPONENT SIDE

AB

PCM

D-135(GR)