Mitsubishi Montero (2002-2004). Manual - part 563

TROUBLE CODE DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

13Ab-9

NOTE: *1 : Minimum value: The test fails if test value is less than this value.

NOTE: *2 : Maximum value: The test fails if test value is greater than this value.

DIAGNOSTIC BY DIAGNOSTIC TEST MODE II

(INCREASED SENSITIVITY)

Required Special Tool:

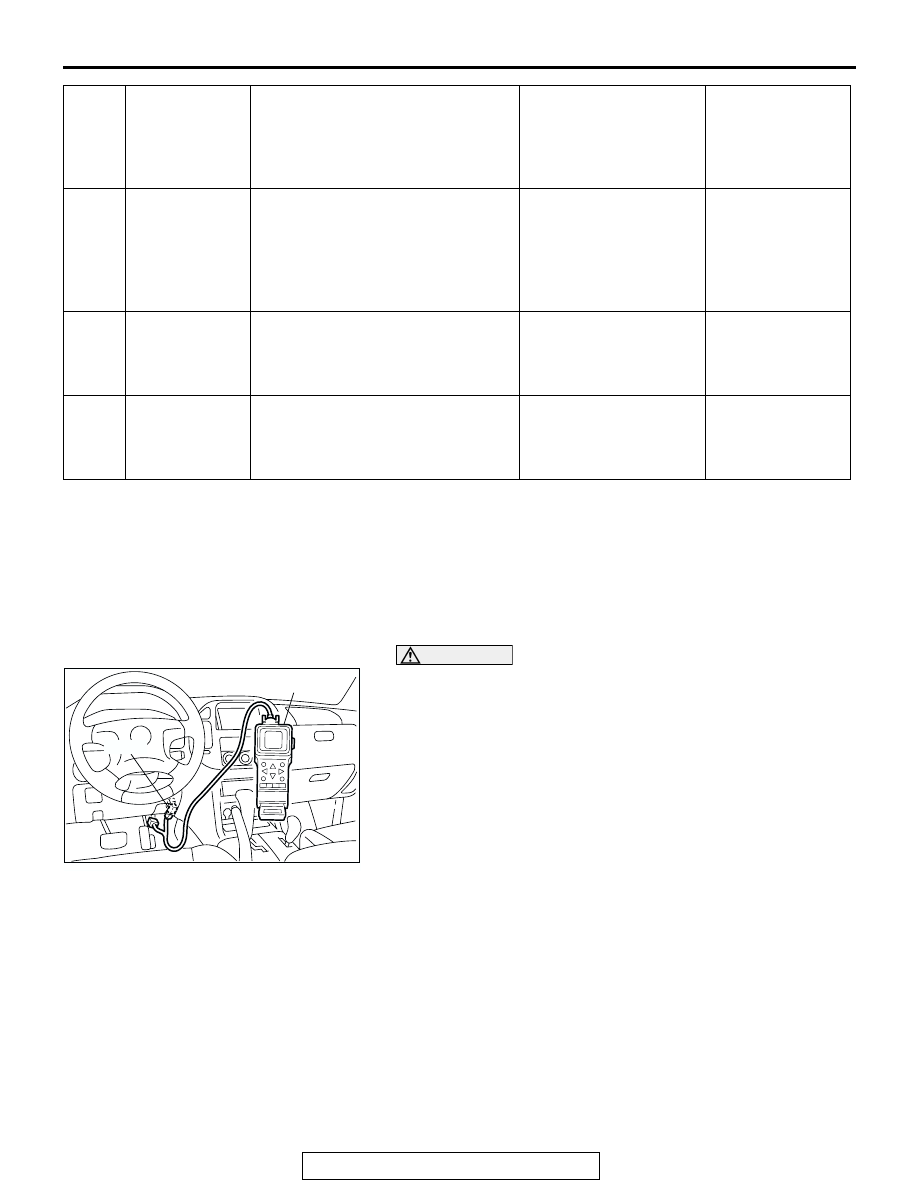

• MB991502: Scan Tool (MUT-II)

CAUTION

To prevent damage to scan tool MB991502, always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting scan tool MB991502.

NOTE: When mode II is selected with MUT-II, the Malfunction

Indicator Lamp (SERVICE ENGINE SOON or Check Engine

Lamp) will light when the powertrain control module (PCM) first

detects the trouble (Note that this is only for emission-related

trouble). At the same time, the relevant diagnostic trouble

codes will be registered. In respect to the comprehensive com-

ponent electrical faults (opens/shorts), the time for the diagnos-

tic trouble code to be registered after the fault occurrence is

four seconds " one second. Therefore, the confirmation of the

trouble symptom and the confirmation after completing repairs

can be reduced. To return to the normal mode I after mode II

has been selected once, the ignition switch must be turned

"OFF" once or mode I must be reselected with MUT-II. The

diagnostic trouble code, system readiness test status and

freeze frame data, etc., will be erased when mode I is returned

to, so record these before returning to mode I.

1. Connect scan tool MB991502 to the data link connector.

2. Turn the ignition switch to the "ON" position.

3. Change the diagnostic test mode of the powertrain control

module to DIAGNOSTIC TEST MODE II (INCREASED

SENSITIVITY).

0A

Heated oxygen

sensor monitor

(Rich/Lean

Switching)

(Bank 2 Sensor

1)

PCM monitors the deteriorated

condition of the heated oxygen

sensor by checking the lean/rich

Switching frequency of the heater

oxygen sensor.

HO2S B2 SENSOR 1

Rich/Lean Switching

Count

Test Result and Limit

Value (min.)

× 1count

0B

Heated oxygen

sensor monitor

(Voltage) (Bank

1 Sensor 2)

PCM checks the output voltage of

the heated oxygen sensor (rear) in

order to monitor whether the heated

oxygen sensor output is stuck.

HO2S B1 SENSOR2

Change in Volt

Test Result and Limit

Value (min.)

× 19.5mV

0C

Heated oxygen

sensor monitor

(Voltage) (Bank

2 Sensor 2)

PCM checks the output voltage of

the heated oxygen sensor (rear) in

order to monitor whether the heated

oxygen sensor output is stuck.

HO2S B2 SENSOR 2

Change in Volt

Test Result and Limit

Value (min.)

× 19.5mV

TEST

ID

MONITORING

ITEM

SIMPLE TECHNICAL

DESCRIPTION

INDICATION OF SCAN

TOOL

CONVERSION

COEFFICIENT IN

USING

GENERAL SCAN

TOOL

ACX01539

16-PIN

MB991502

AC