Mitsubishi Montero (2002-2004). Manual - part 415

WHEEL AND TIRE DIAGNOSIS

TSB Revision

WHEEL AND TIRE

31-3

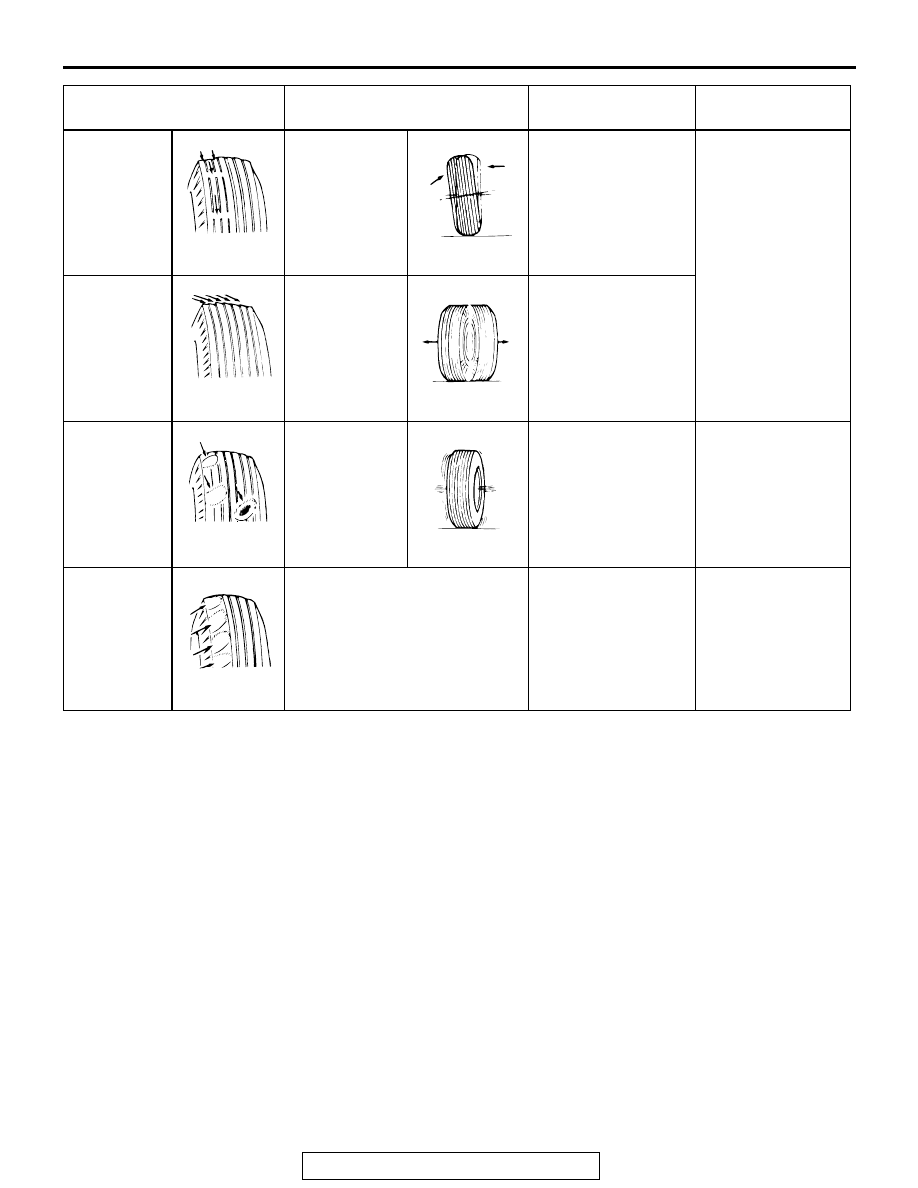

Wear on one

side

Excessive

camber

Check the camber.

Refer to GROUP

33A, On-vehicle

service

− Front

wheel alignment

check and

adjustment

.

Feathered

edge

Incorrect toe-in

Adjust the toe-in.

Bald spots

Unbalanced

wheel

Balance the wheels.

−

Scalloped

wear

Lack of rotation of tires or worn

or out-of-alignment suspension

Rotate the tires, and

check the front

suspension

alignment.

Refer to GROUP

33A, On-vehicle

service

− Front

wheel alignment

check and

adjustment

.

SYMPTOM

PROBABLE CAUSE

REMEDY

REFERENCE

PAGE

ACX00928 AB

ACX00929 AB

ACX00930AB

ACX00931AB

ACX00932AB

ACX00933 AB

ACX00934