Mitsubishi Montero (2002-2004). Manual - part 377

INPUT SIGNAL PROCEDURES

TSB Revision

SWS INPUT SIGNAL PROCEDURES

54Bc-55

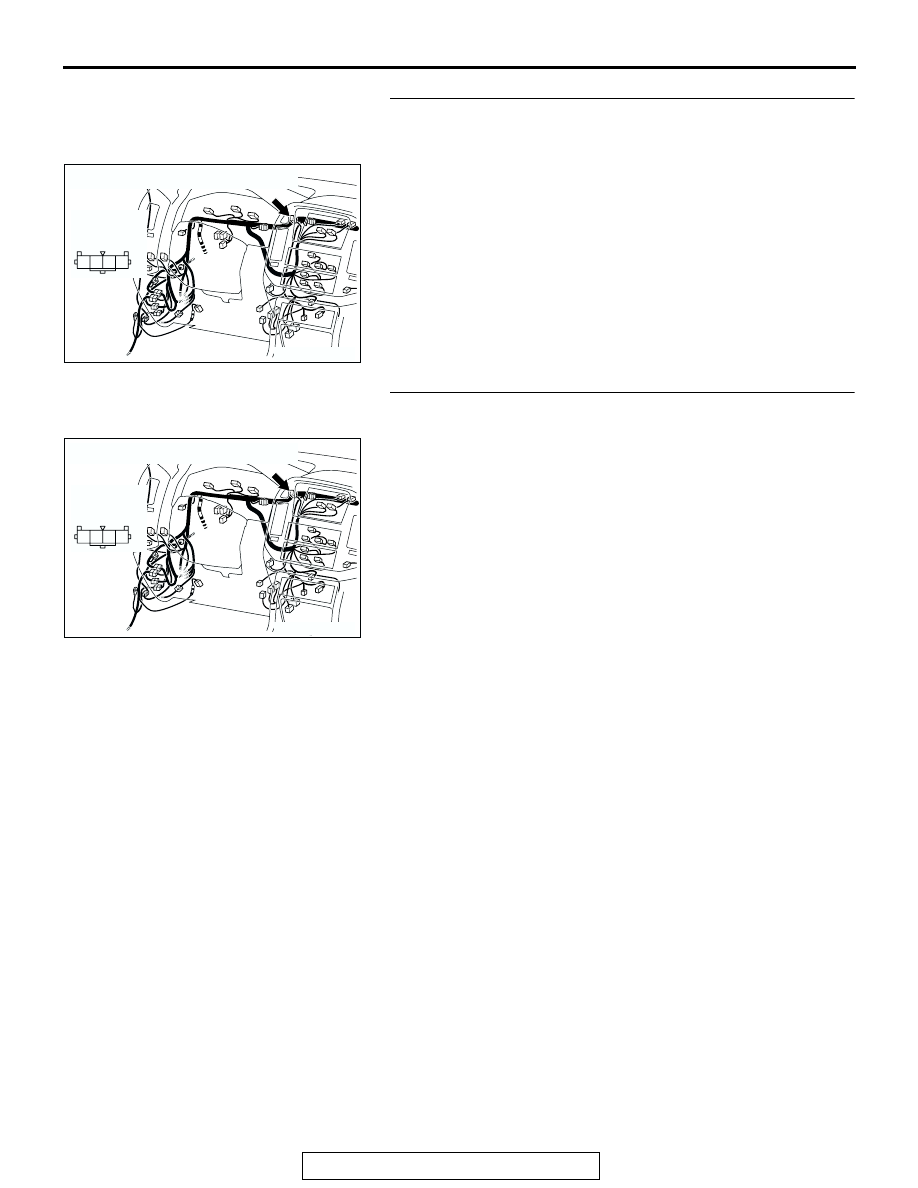

STEP 3. Check hazard warning light switch connector D-

103 for loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Is hazard warning light switch connector D-103 in good

condition?

YES : Go to Step 4.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

. If the equipment, which are described in

"CIRCUIT OPERATION", work normally, the input

signal from the hazard warning light switch should be

normal.

STEP 4. Check the wiring harness between hazard warning

light switch connector D-103 (terminal 2) and ground.

Q: Is the wiring harness between hazard warning light

switch connector D-103 (terminal 2) and ground in good

condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the

connector(s) may have loose, corroded or damaged

terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. If the

equipment, which are described in "CIRCUIT

OPERATION", work normally, the input signal from

the hazard warning light switch should be normal.

AC204170

CONNECTOR : D-103

AK

1

2

4 3

HARNESS

SIDE

D-103

AC204170

CONNECTOR : D-103

AK

1

2

4 3

HARNESS

SIDE

D-103