Mitsubishi Montero (2002-2004). Manual - part 228

PROPELLER SHAFT DIAGNOSIS

TSB Revision

PROPELLER SHAFT

25-3

SYMPTOM CHART

M1251002000044

SYMPTOM PROCEDURES

INSPECTION PROCEDURE 1: Noise at Start

DIAGNOSIS

STEP 1. Check if the propeller shaft mounting

bolts and nuts are loose. (Refer to

Q: Are the bolts and nuts tightened to 60

± 10 N⋅m (45

± 7 ft-lb)?

YES :

Go to Step 2.

NO :

Tighten the bolts and nuts to 60

± 10 N⋅m

(45

± 7 ft-lb). Then go to Step 5.

STEP 2. Check the universal joint's journal

bearing of front propeller shaft for wear or

damage. (Refer to

Q: Is wear or damage apparent?

YES :

Replace the journal bearing. Then go to

Step 5.

NO :

Go to Step 3.

STEP 3. Check the BJ assembly's spline of front

propeller shaft for wear.

Q: Is wear apparent?

YES :

Replace the propeller shaft. Then go to Step

NO :

Go to Step 4.

STEP 4. Check the flange sleeve spline of rear

propeller shaft for wear.

Q: Is wear apparent?

YES :

Replace the rear propeller shaft. Then go to

Step 5.

NO :

Go to Step 5.

STEP 5. Retest the system.

Q: Is the abnormal noise eliminated?

YES :

The procedure is complete.

NO :

Recheck from Step 1.

INSPECTION PROCEDURE 2: Noise and Vibration at High Speed

DIAGNOSIS

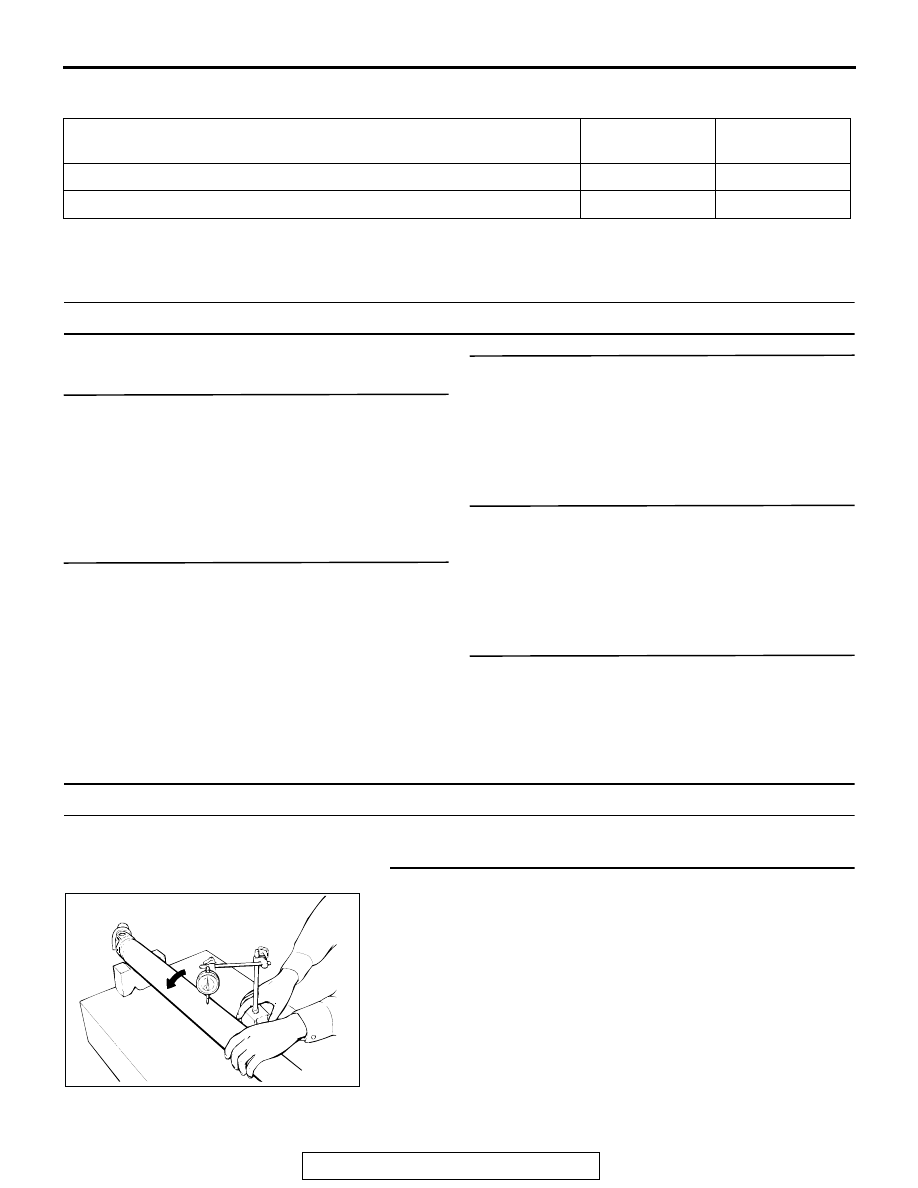

STEP 1. Check the front propeller shaft run-out.

Q: Is the measured value within the limit: 0.5 mm (0.02

inch)?

YES : Go to Step 2.

NO : Replace the front propeller shaft. Then go to Step 6.

SYMPTOMS

INSPECTION

PROCEDURE

REFERENCE

PAGE

Noise at start

1

Noise and vibration at high speed

2

ACX00643