Mitsubishi Montero (2002-2004). Manual - part 206

HUB AND KNUCKLE ASSEMBLY

TSB Revision

FRONT AXLE

26-21

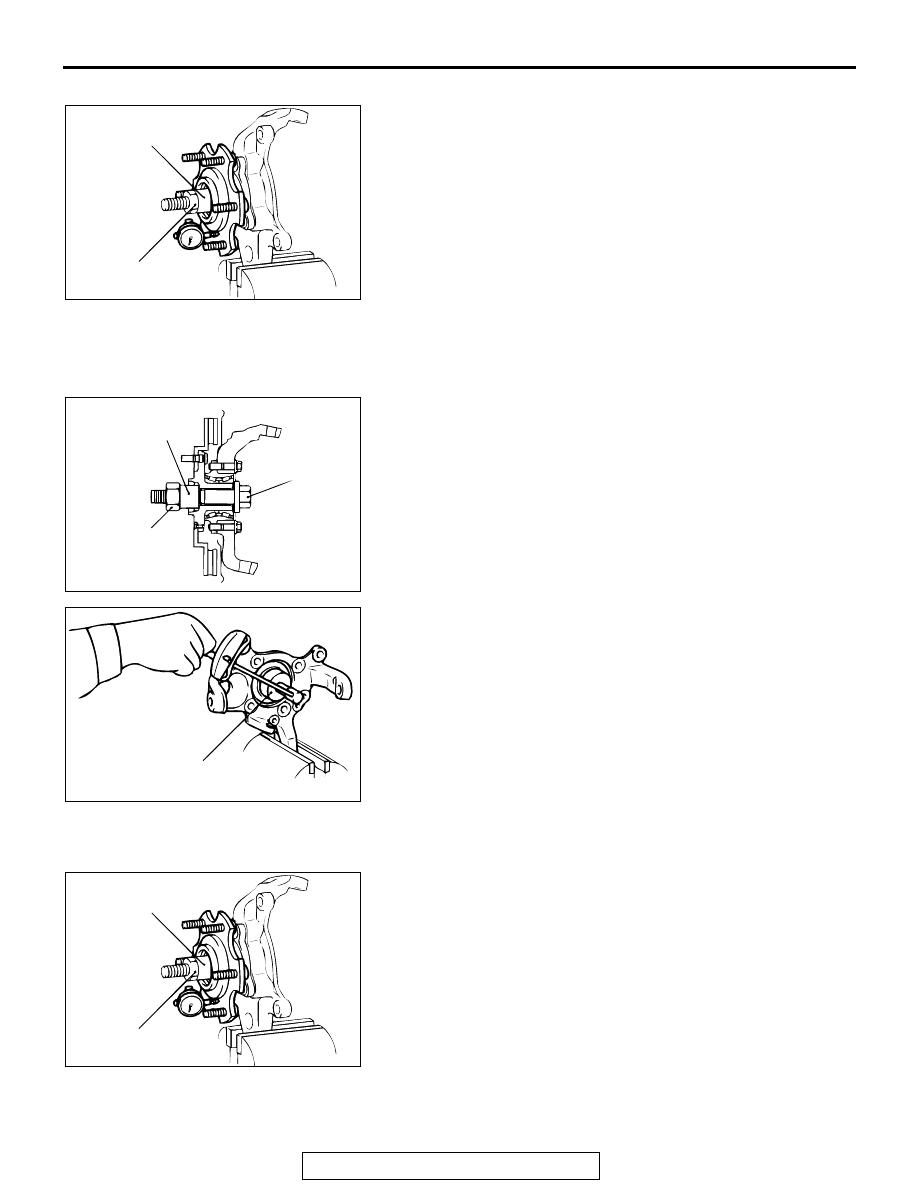

WHEEL BEARING BACKLASH CHECK

1. Secure the knuckle in a vice to measure backlash in the

wheel bearing.

Limit: 0 mm (0 inch)

2. If the value of backlash in hub axis cannot be obtained when

tightened to the specified torque 255

± 29 N⋅m (188 ± 21 ft-

lb), check mounting bolt for hub and knuckle assembly. If no

defects are found, replace hub assembly.

INSPECTION OF HUB ROTATION STARTING

TORQUE

M1261007200033

1. Tighten special tools in hub and knuckle assembly to the

specified torque.

Specified torque: 255

± 29 N⋅m (188 ± 21 ft-lb)

2. Measure the hub rotation starting torque with special tools.

Limit: 1.75 N

⋅m (15.48 in-lb)

3. Hub rotation starting torque must be under the limit value

and there should be no roughness when rotating the hub.

WHEEL BEARING PLAY CHECK

M1261001100124

1. Secure the knuckle in a vice to measure backlash in the

wheel bearing.

Limit: 0 mm (0 inch)

2. If the value of backlash in hub axis cannot be obtained when

tightened to the specified torque 255

± 29 N⋅m (188 ± 21 ft-

lb), check mounting bolt for hub and knuckle assembly. If no

defects are found, replace hub assembly.

ACX00977AB

MB990998

255

±

29 N

•

m

188

±

21 ft-lb

ACX00975 AB

MB990998

BOLT

255

±

29 N

•

m

188

±

21 ft-lb

HOLD THE BOLT

AND TIGHTEN THE

NUT.

ACX00976 AB

MB990326

ACX00977AC

MB990998

255

±

29 N

·

m

188

±

21 ft-lb