Mitsubishi Montero (2002-2004). Manual - part 185

HOW TO USE TROUBLESHOOTING/INSPECTION SERVICE POINTS

TSB Revision

GENERAL <BODY AND CHASSIS>

00-9

.

HARNESS INSPECTION

Check for an open or short circuit in the harness

between the terminals which were faulty according to

the connector measurements. Carry out this inspec-

tion while referring to GROUP 00E, Harness Con-

nector Inspection. Here, "Check harness between

power supply and terminal xx" also includes check-

ing for blown fuse. For inspection service points

when there is a blown fuse, refer to "Inspection Ser-

vice Points for a Blown Fuse."

.

MEASURES TO TAKE AFTER REPLACING THE

ECU

If the trouble symptoms have not disappeared even

after replacing the ECU, repeat the inspection proce-

dure from the beginning.

ACX00862

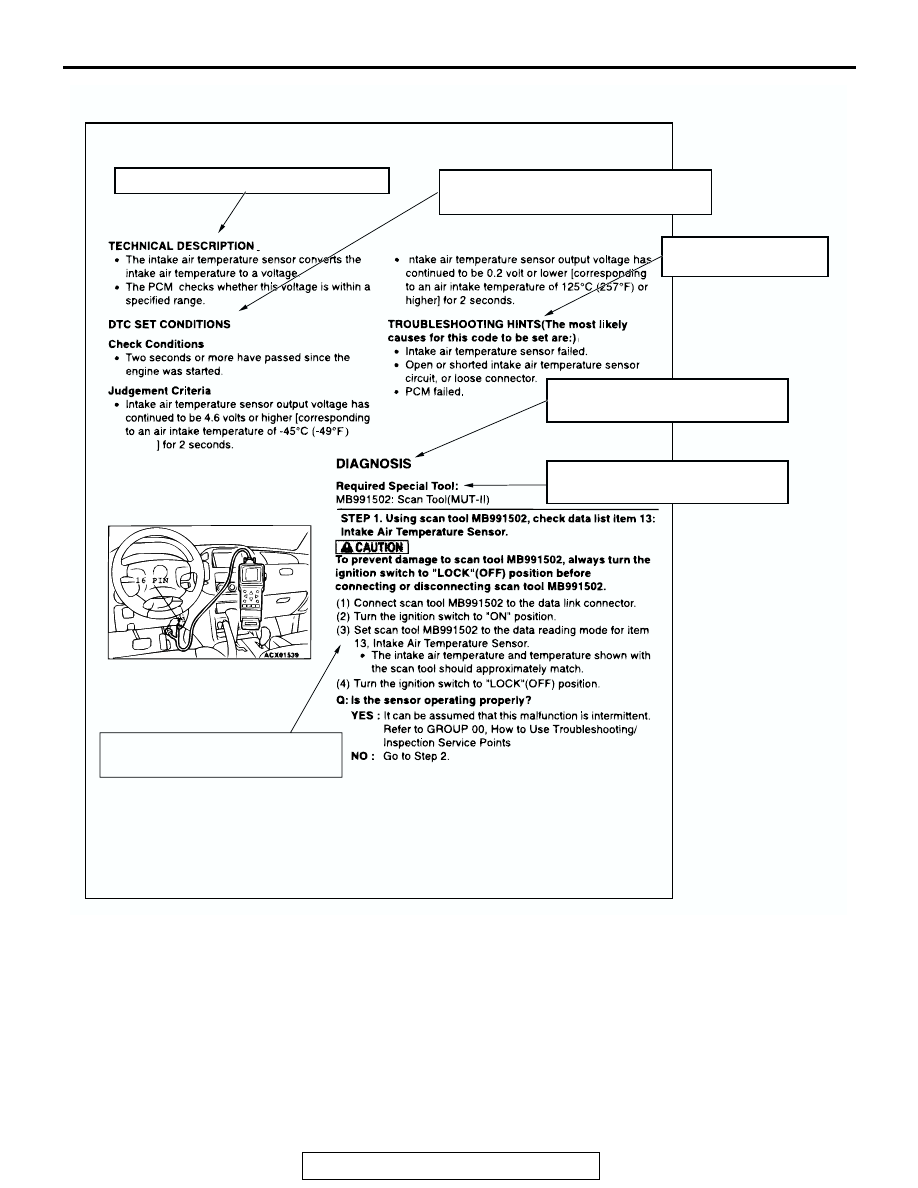

(5) Explains about technical details.

(6) Describes the conditions for that DTC

being set (stored).

(7) Describes possible

cause(s)for that DTC.

(8) Start of the diagnosis procedure

for that DTC.

(9) Identifies the special tool(s)

necessary for diagnosing that DTC.

(10) Provides the inspection procedure

for that DTC step by step.

lower

or

.

AH