Mitsubishi Montero (2002-2004). Manual - part 63

REAR AIR CONDITIONING DIAGNOSIS

TSB Revision

HEATER, AIR CONDITIONING AND VENTILATION

55A-115

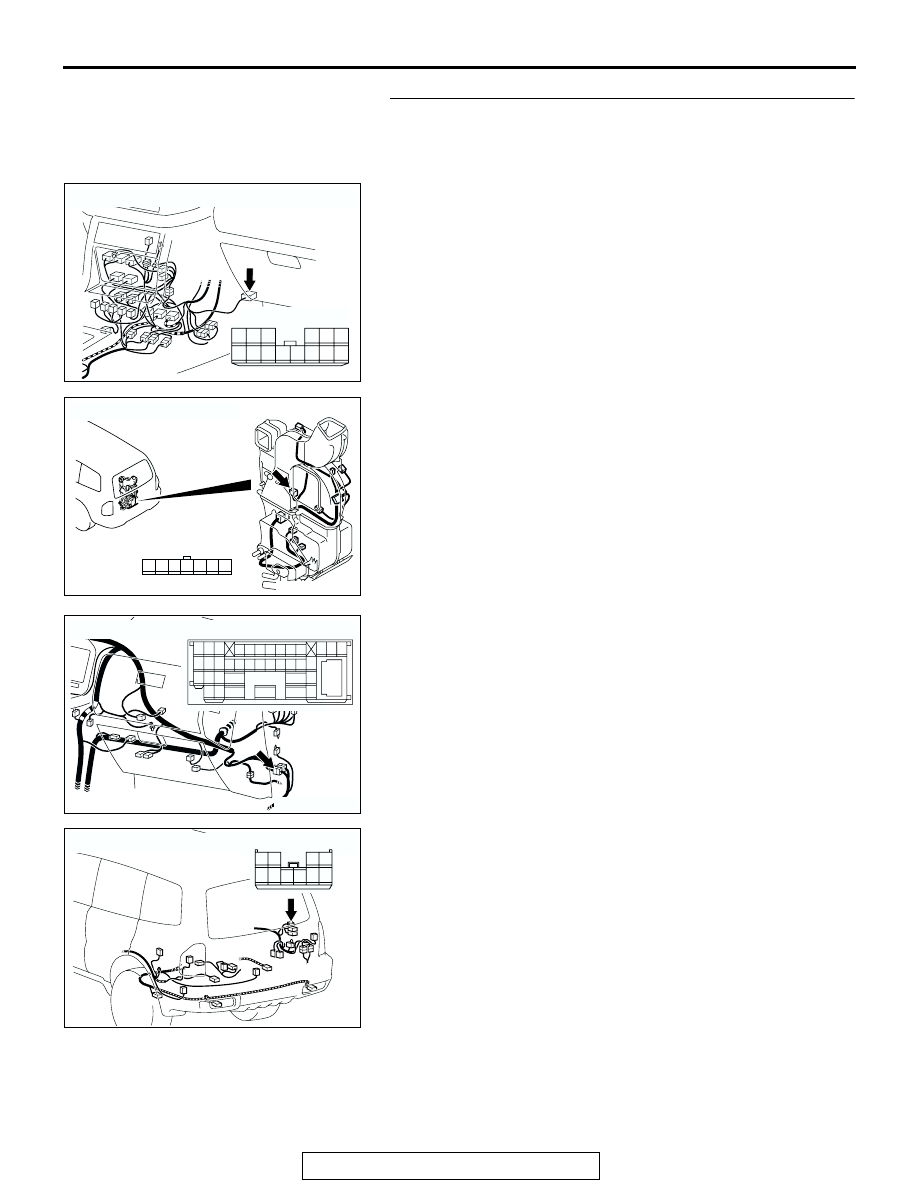

STEP 11. Check the wiring harness between rear A/C

control unit connector E-20 (terminal 9, 10 and 11) and

mode selection damper control motor connector G-22-3

(terminal 6, 4 and 3).

NOTE: Also check intermediate connector D-112 and rear A/C

unit connector G-22. If intermediate connector D-112 and rear

A/C unit connector G-22 is damaged, repair or replace the con-

nector as described in GROUP 00E, Harness Connector

Inspection

.

Q: Is the wiring harness between rear A/C control unit

connector E-20 (terminal 9, 10 and 11) and mode

selection damper control motor connector G-22-3

(terminal 6, 4 and 3) in good condition?

YES : Go to Step 12.

NO : Repair the wiring harness. Check that the rear air

conditioning works normally.

AC204176

CONNECTOR : E-20

AY

HARNESS SIDE

7

8

3

10 9

2

4

11

1312

5

14

6

1

AC204698

CONNECTOR : G-22-3

AG

HARNESS SIDE

7 6 5 4 3 2 1

AC204171 AL

CONNECTOR : D-112

2 3

27

32

28

33

16

15

4 5

19

18

29

17

34

7 8

35

22

21

9 10

30

36

31

37

25

24

23

6

20

1

14

26

11

13

12

38

AC204179

CONNECTOR : G-22

AP

HARNESS SIDE

1

5

7

8

2

6

10

4

9

3