Mitsubishi Montero (2002-2004). Manual - part 3

FUEL FILLER LID

TSB Revision

BODY

42-9

REMOVAL SERVICE POINT

.

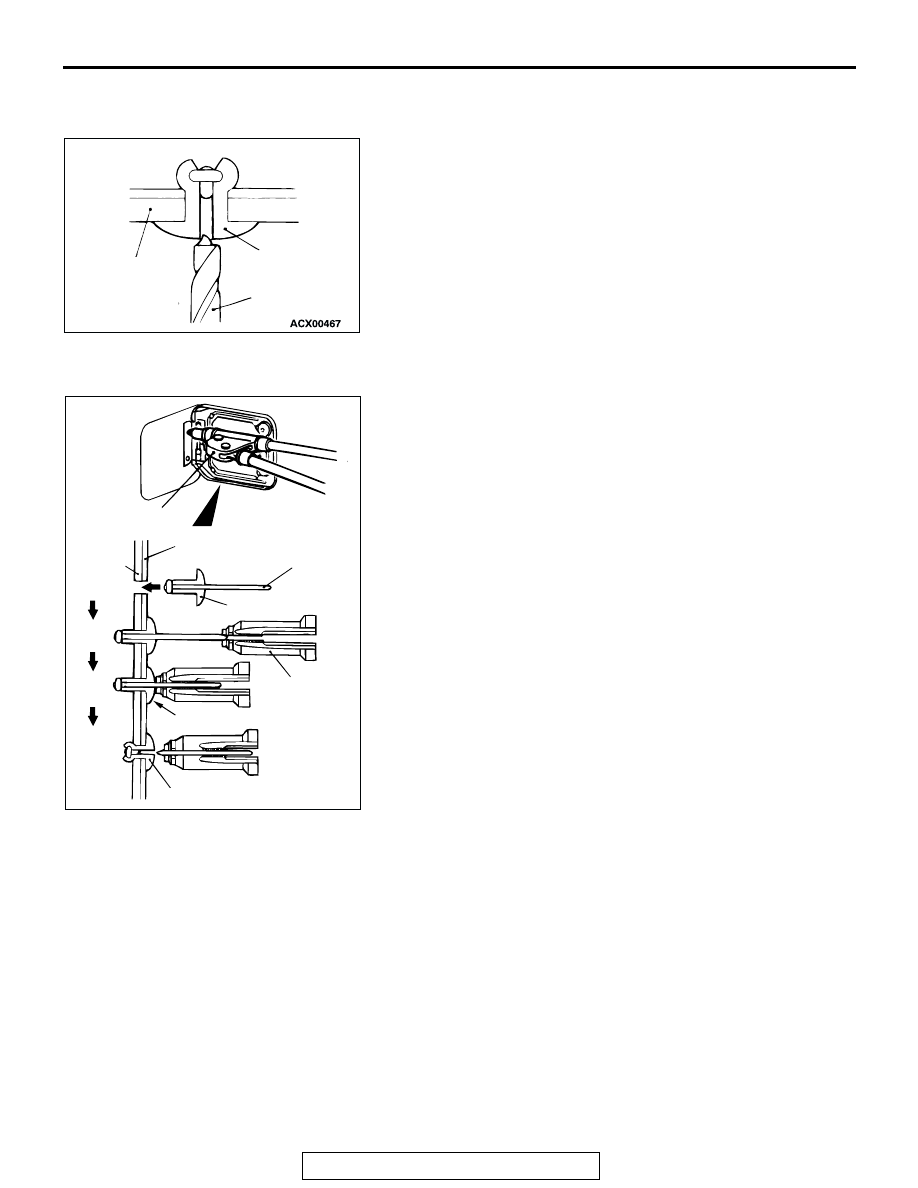

<<A>> RIVET REMOVAL

Use a drill [

φ6.5 − 7.5 mm (φ0.25 − 0.29 inch)] to break the rivet

by drilling a hole, and remove the rivet.

INSTALLATION SERVICE POINT

.

>>A<< RIVET INSTALLATION

1. Insert the rivet [

φ6.4mm (φ0.25 inch)] into the body panel

and wide fender.

2. Insert the "A" side of the rivet into the riveter.

3. Pressing the flange surface of the rivet, move the handle of

the riveter.

4. The thinnest point of "A" is cut and the rivet is held in the

position.

DRILL

RIVET

FUEL FILLER

DOOR PANEL

AB

ACX00468

RIVETER

BODY

PANEL

FUEL FILLER DOOR

PANEL ASSEMBLY

RIVETER

RIVET

FLANGE SURFACE

RIVET

A

1

2

3

4

AB