Mitsubishi Montero (1998+). Manual - part 144

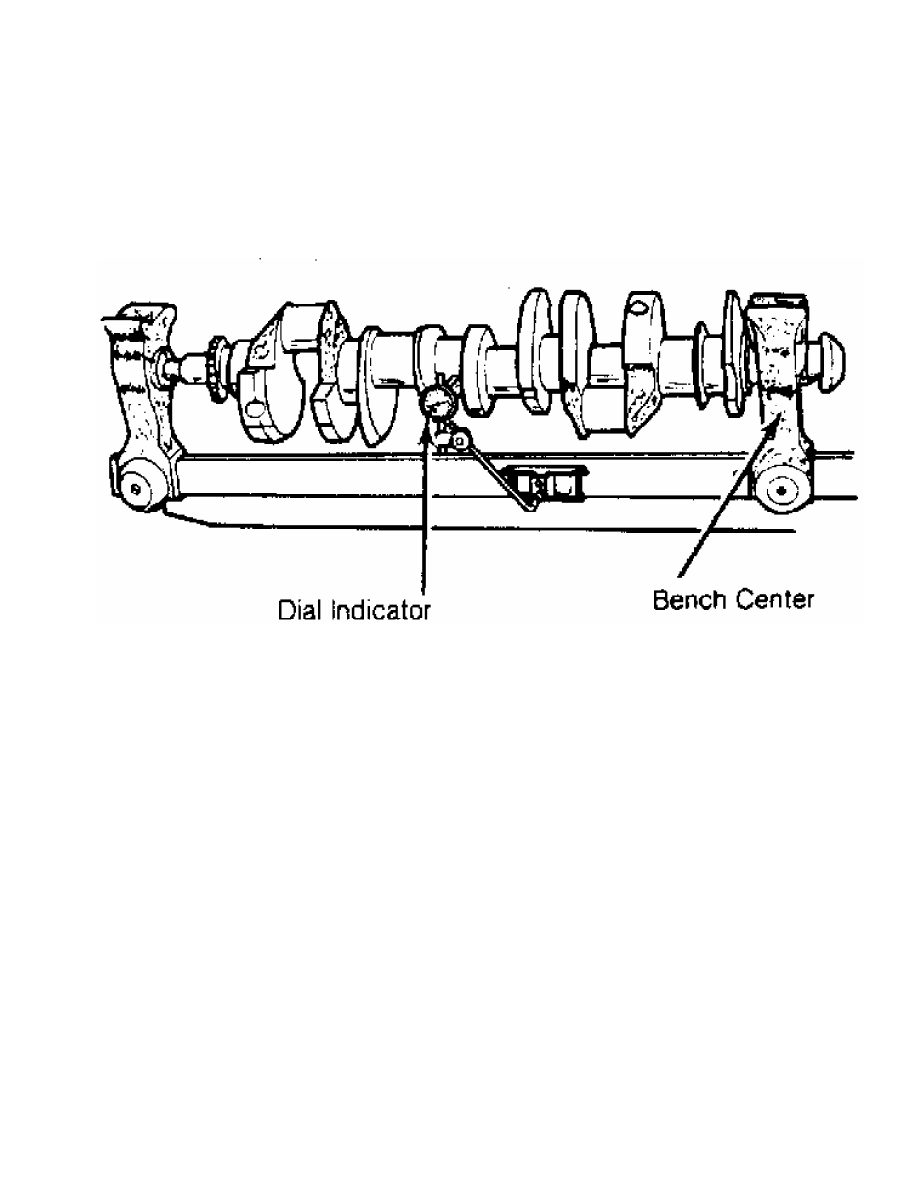

with tip resting on the main bearing journal area. See Fig. 21.

Rotate crankshaft and note reading. Journal runout must not exceed

specification. Repeat procedure on all main bearing journals.

Crankshaft must be replaced if runout exceeds specification.

Fig. 21: Measuring Crankshaft Main Bearing Journal Runout - Typical

This Graphic For General Information Only

INSTALLATION

Install upper main bearing in cylinder block. Ensure lock

tab is properly located in cylinder block. Install bearings in main

bearing caps. Ensure all oil passages are aligned. Install rear seal

(if removed).

Ensure crankshaft journals are clean. Lubricate upper main

bearings with clean engine oil. Carefully install crankshaft. Check

each main bearing clearance using Plastigage method. See

MAIN & CONNECTING ROD BEARING CLEARANCE in this article.

Once clearance is checked, lubricate lower main bearing and

journals. Install main bearing caps in original location. Install rear

seal in rear main bearing cap (if removed). Some rear main bearing

caps require sealant to be applied in corners to prevent oil leakage.

Install and tighten all bolts except thrust bearing cap to

specification. Tighten thrust bearing cap bolts finger tight only.

Thrust bearing must be aligned. On most applications, crankshaft

must be moved rearward then forward. Procedure may vary with

manufacturer. Thrust bearing cap is then tighten to specification.

Ensure crankshaft rotates freely. Crankshaft end play should be

checked. See CRANKSHAFT END PLAY in this article.

CRANKSHAFT END PLAY

Dial Indicator Method

Crankshaft end play can be checked using dial indicator.

Mount dial indicator on rear of cylinder block. Position dial

indicator tip against rear of crankshaft. Ensure tip is resting

against flat surface.

Pry crankshaft rearward. Adjust dial indicator to zero.