Mitsubishi Montero (1998+). Manual - part 67

Removal & Installation

1) Drain master cylinder. Remove cotter pin, washer and

clevis pin. Disconnect push rod from clutch pedal. Remove and plug

hydraulic line at clutch master cylinder.

2) Remove retaining nuts, clutch master cylinder and gasket.

To install, reverse removal procedure. Apply grease to clevis pin

before installing. Fill reservoir and bleed clutch system. See

BLEEDING CLUTCH HYDRAULIC SYSTEM.

CLUTCH RELEASE CYLINDER

Removal & Installation

Remove and plug hydraulic line at release cylinder. Remove

cylinder-to-transmission bolts. Remove clutch release cylinder. To

install, reverse removal procedure. Apply grease to push rod-to-

release fork contact area. Bleed clutch system. See

BLEEDING CLUTCH HYDRAULIC SYSTEM.

BLEEDING CLUTCH HYDRAULIC SYSTEM

Attach hose to bleeder fitting located on clutch release

cylinder, next to hydraulic line. Submerge other end of hose in

container half full of clean brake fluid. Fill reservoir with brake

fluid. Open bleeder fitting. Have assistant press clutch pedal to full

release position. Close bleeder fitting. Release clutch pedal. Repeat

until air bubbles no longer emerge from hose. Refill reservoir.

OVERHAUL

CLUTCH MASTER CYLINDER

NOTE: DO NOT disassemble piston assembly.

Disassembly

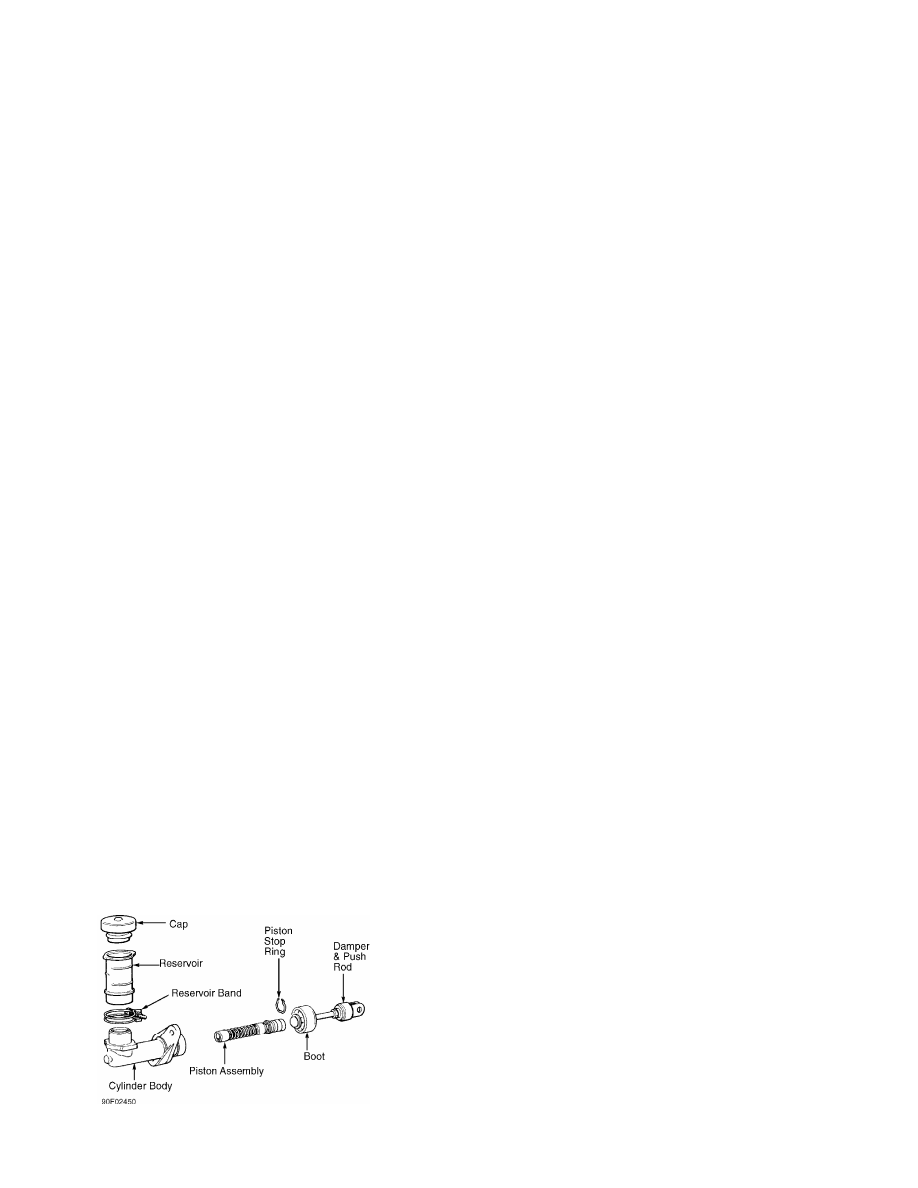

Remove piston stop ring, damper and push rod assembly. See

Fig. 6. Remove piston assembly. Note position of reservoir band for

reassembly reference. Remove reservoir.

Inspection & Reassembly

Inspect components for corrosion, scoring or damage. Replace

if necessary. Apply brake fluid to components during reassembly. On

Montero, adjust clutch master cylinder push rod to 5.90" (150 mm). On

Montero Sport, push rod adjustment is correct after adjusting clutch

pedal free play and pedal height. See CLUTCH PEDAL FREE PLAY and

CLUTCH PEDAL HEIGHT under ADJUSTMENTS. To reassemble, reverse

disassembly procedure. Ensure piston moves freely in bore.

Fig. 6: Exploded View Of Clutch Master Cylinder (Typical)

Courtesy of Mitsubishi Motor Sales of America.