Mitsubishi Montero (1998+). Manual - part 40

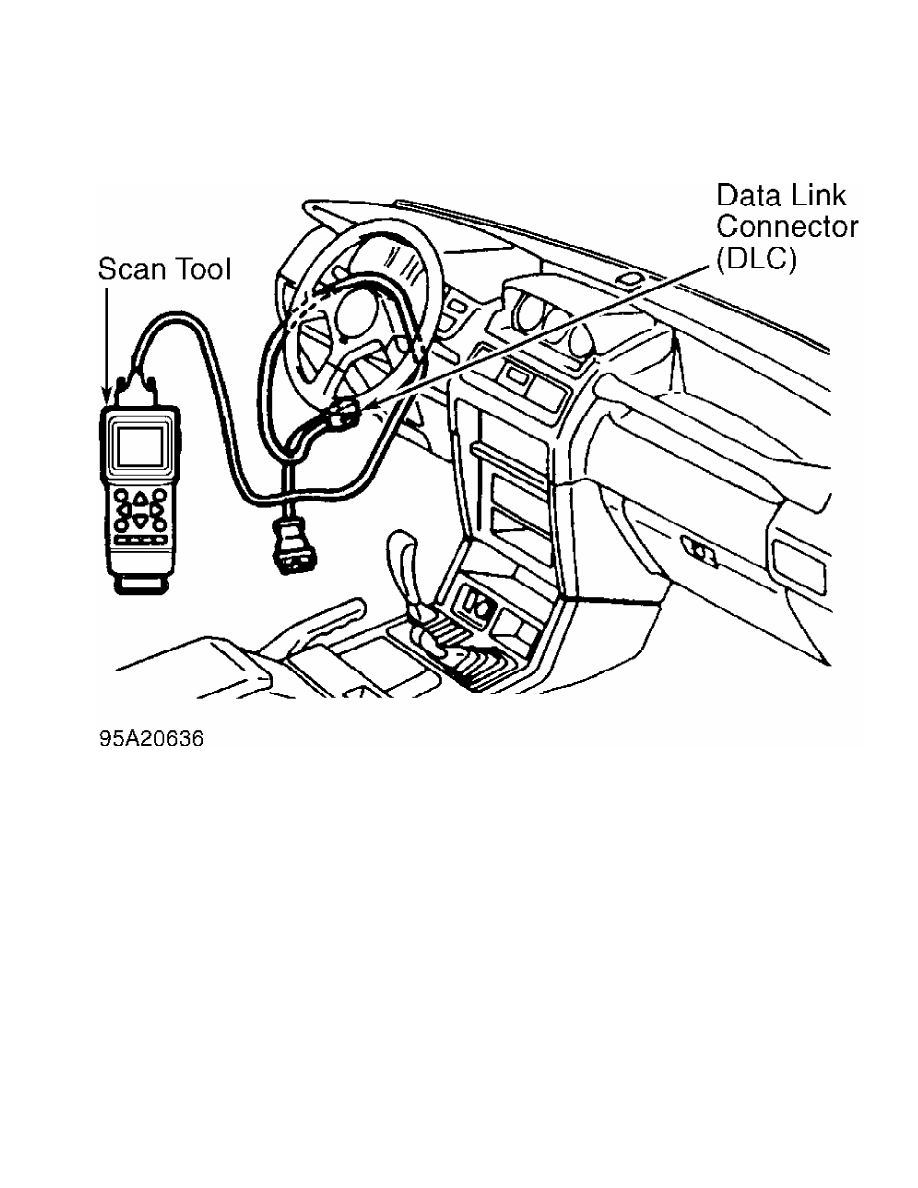

Fig. 5: Retrieving Codes Using Scan Tool

Courtesy of Mitsubishi Motor Sales of America.

Retrieving Codes Using Oil Temperature Warning Light

1) Using jumper wire, ground DLC terminal No. 1. See Fig. 6.

Note number of flashes from oil temperature warning light on

instrument panel. See Fig. 7. If normal system operation exists, oil

temperature warning light will blink 2 times per second. See Fig. 8.

2) If system is operating correctly and no DTC exists, turn

ignition off and remove jumper wire. If DTC exists, oil temperature

warning light will flash once every 2 seconds. The number of flashes

will equal first digit of DTC. After a pause of 2 seconds, second

digit will be displayed. Oil temperature warning light will flash once

every half second for second digit. See Fig. 8.

3) If more than one DTC exists, next DTC will be displayed

after pause of 3 seconds. Smallest DTC number will be first. DTCs will

be repeated.

4) Once DTC is obtained, determine probable cause and

symptom. See DIAGNOSTIC TROUBLE CODE IDENTIFICATION table. To trouble

shoot DTC, see DIAGNOSTIC TESTS. Turn ignition off and remove jumper

wire.

NOTE: Once repairs have been performed, DTCs must be cleared from

TCM memory. See CLEARING DIAGNOSTIC TROUBLE CODES (DTC).