Mitsubishi Montero (1991+). Manual - part 317

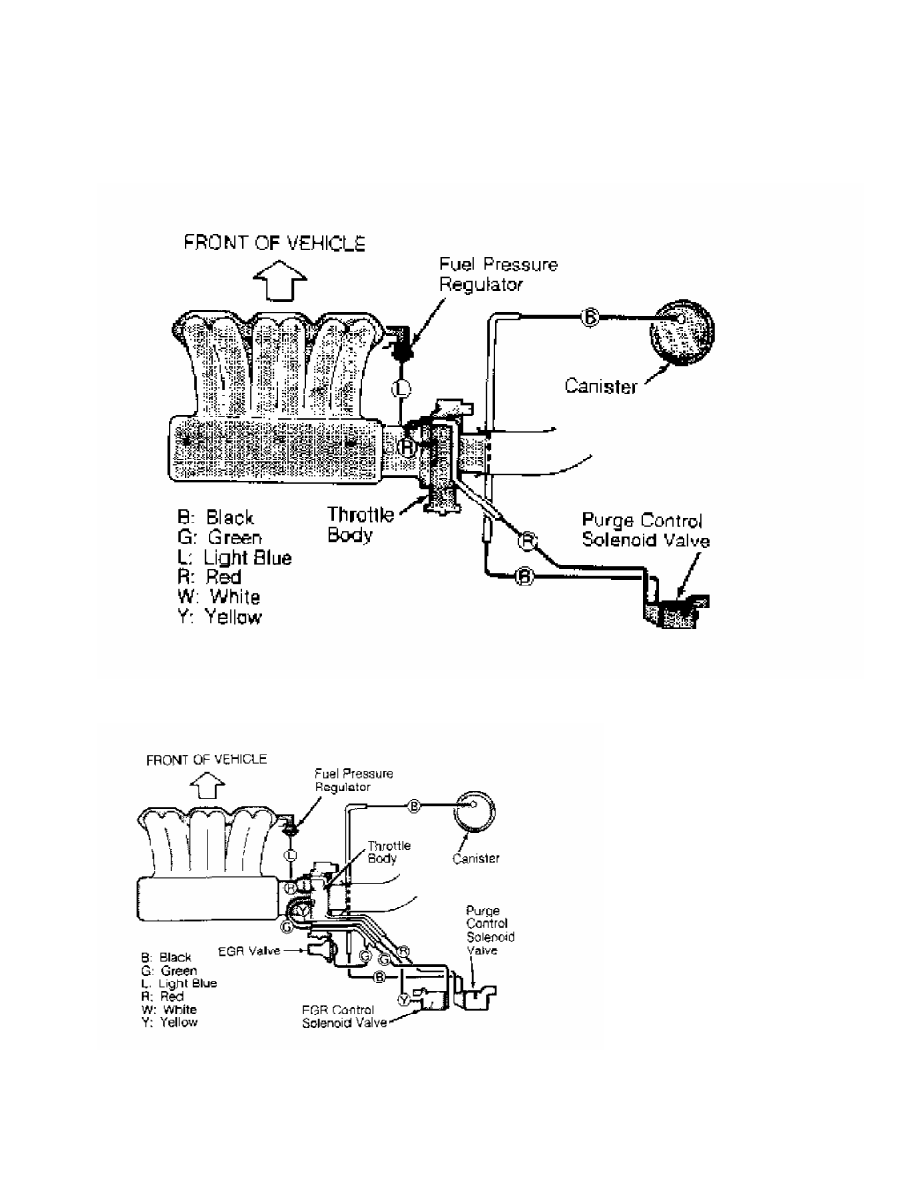

Fig. 21: Vacuum Diagram (Stealth & 3000GT/Fed.)

Courtesy of Chrysler Motors.

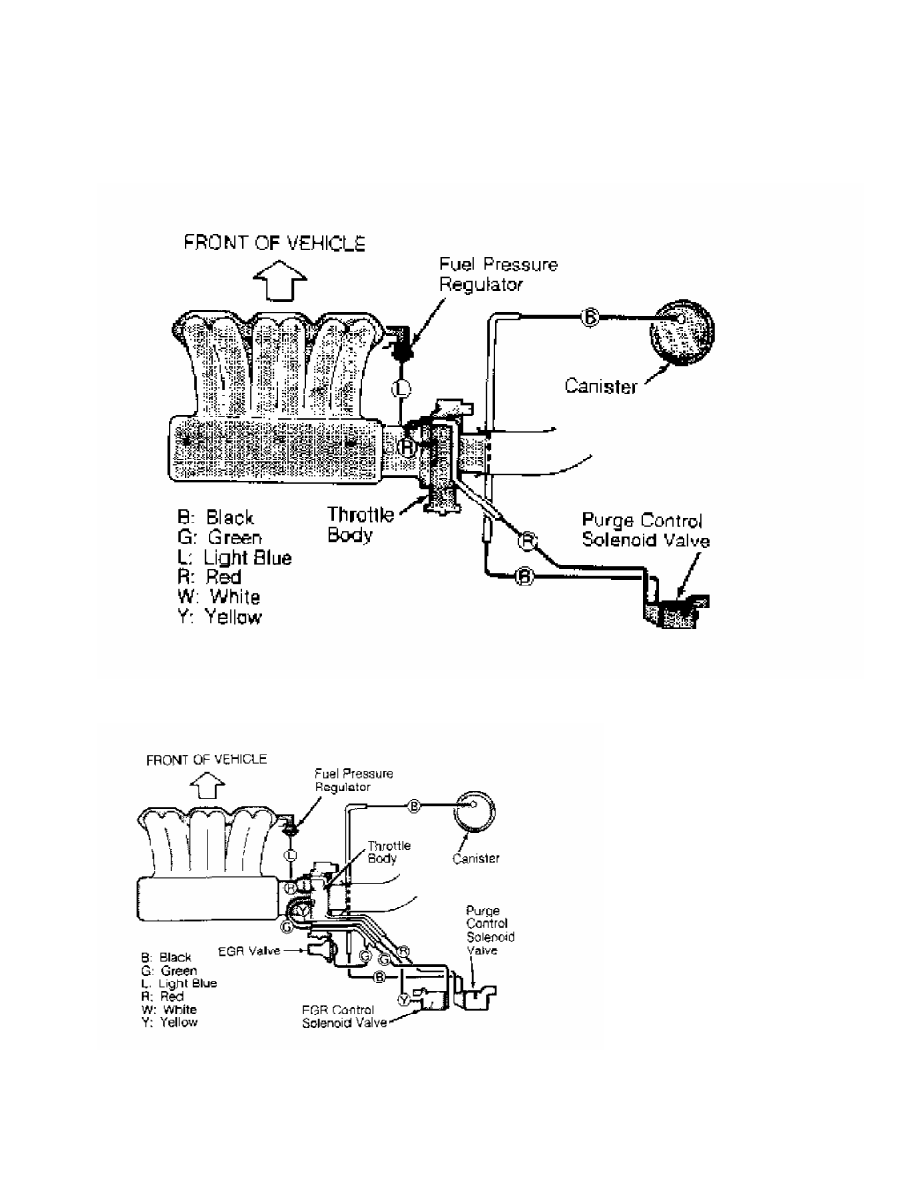

Fig. 22: Vacuum Diagram (Stealth & 3000GT/Calif.)

Courtesy of Chrysler Motors.

|

|

|

Fig. 21: Vacuum Diagram (Stealth & 3000GT/Fed.) Courtesy of Chrysler Motors. Fig. 22: Vacuum Diagram (Stealth & 3000GT/Calif.) Courtesy of Chrysler Motors. |