Mitsubishi Montero (1991+). Manual - part 6

tensioner center bolt. Using Tensioner Pulley Socket (MD998767) and

torque wrench, apply 84 INCH lbs. (9.5 N.m). See Fig. 17. Retighten

center bolt to specification. See TORQUE SPECIFICATIONS (3000GT) table

at end of article. Ensure tensioner pulley does not rotate while

tightening center bolt.

10) Ensure wire installed in automatic tensioner can be

easily removed and installed. Rotate crankshaft 2 revolutions

clockwise. Wait 5 minutes. Ensure wire can still be removed and

installed easily or automatic tensioner rod projects from tensioner

body .150-.177" (3.8-4.5 mm).

11) If rod projection is not to specification, repeat steps

9) and 10). To complete installation, reverse removal procedure.

Install proper length bolts in timing belt covers. Install bolts into

engine support bracket in reverse order of removal sequence. See

Fig. 10. Tighten bolts to specification. See TORQUE SPECIFICATIONS

(3000GT) table.

NOTE: Engine support bracket reamer bolt must be tightened slowly

while spraying lubricant on bolt.

CAMSHAFT & ROCKER ARMS

Removal (SOHC)

1) Remove PCV valve and breather hoses. Remove timing belt,

camshaft sprocket and rear timing belt cover. See TIMING BELT under

REMOVAL & INSTALLATION. Remove rocker covers and gaskets. Remove

circular packing from rear of camshafts.

2) Remove camshaft oil seal from front of cylinder head or

distributor adapter. Remove distributor adapter and "O" ring. Install

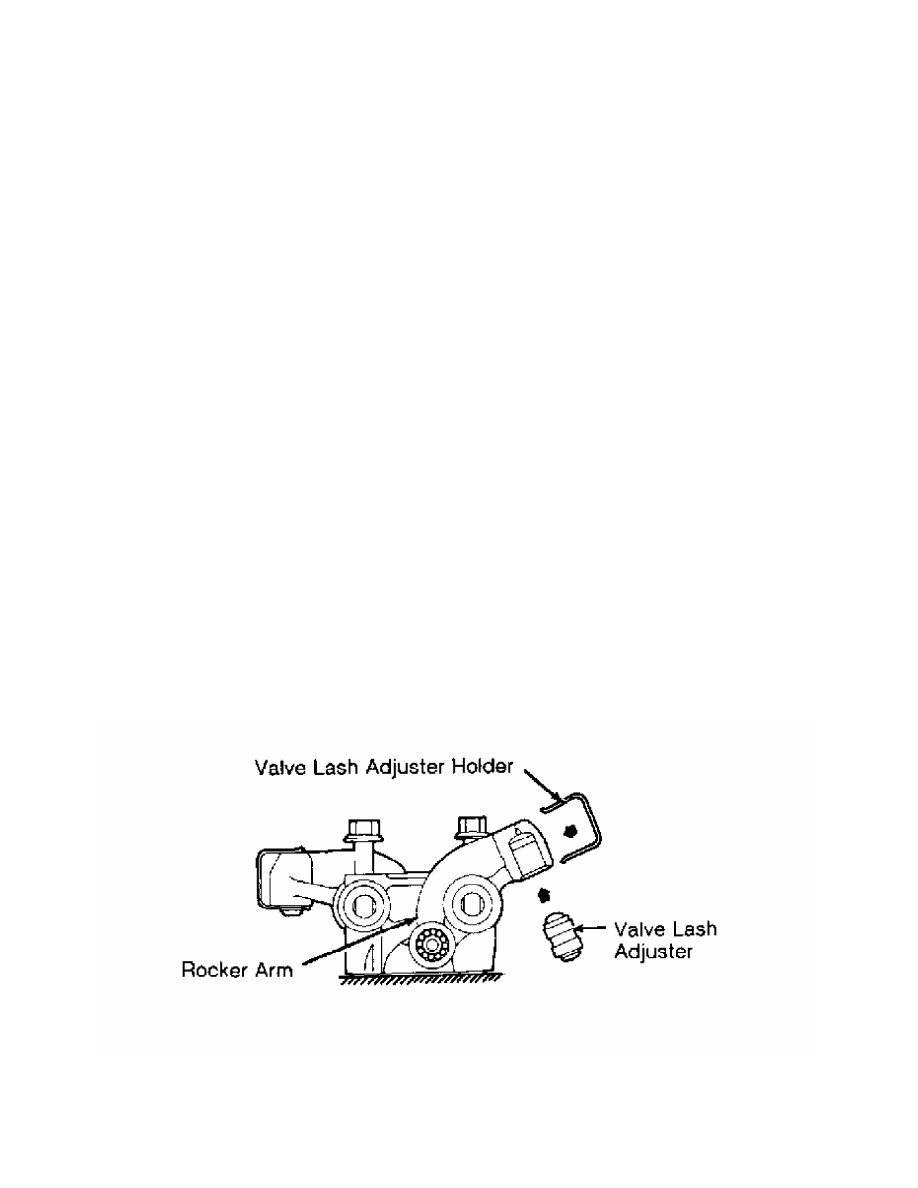

Valve Lash Adjuster Holder (MD998443) on rocker arm. See Fig. 18. Note

arrow marks on bearing caps and cylinder head. See Fig. 19.

3) Bearing cap location number is stamped on front side of

bearing cap. Remove bearing cap bolts. Keep components in order for

reassembly reference. Remove rocker arm assembly. Remove camshaft from

cylinder head.

Fig. 18: Installing Valve Lash Adjuster Holder (SOHC)

Courtesy of Mitsubishi Motor Sales of America, Inc.