Mitsubishi Montero (1991+). Manual - part 4

revolutions clockwise. DO NOT rotate counterclockwise. Realign all

timing marks. Tighten belt tensioner bolts to specification. Using

belt tension gauge, measure belt tension halfway between crankshaft

sprocket and camshaft sprocket on side opposite belt tensioner.

7) Belt tension should be 57.3-83.8 lbs. (26-38 kg). To

install remaining components, reverse removal procedure. Install

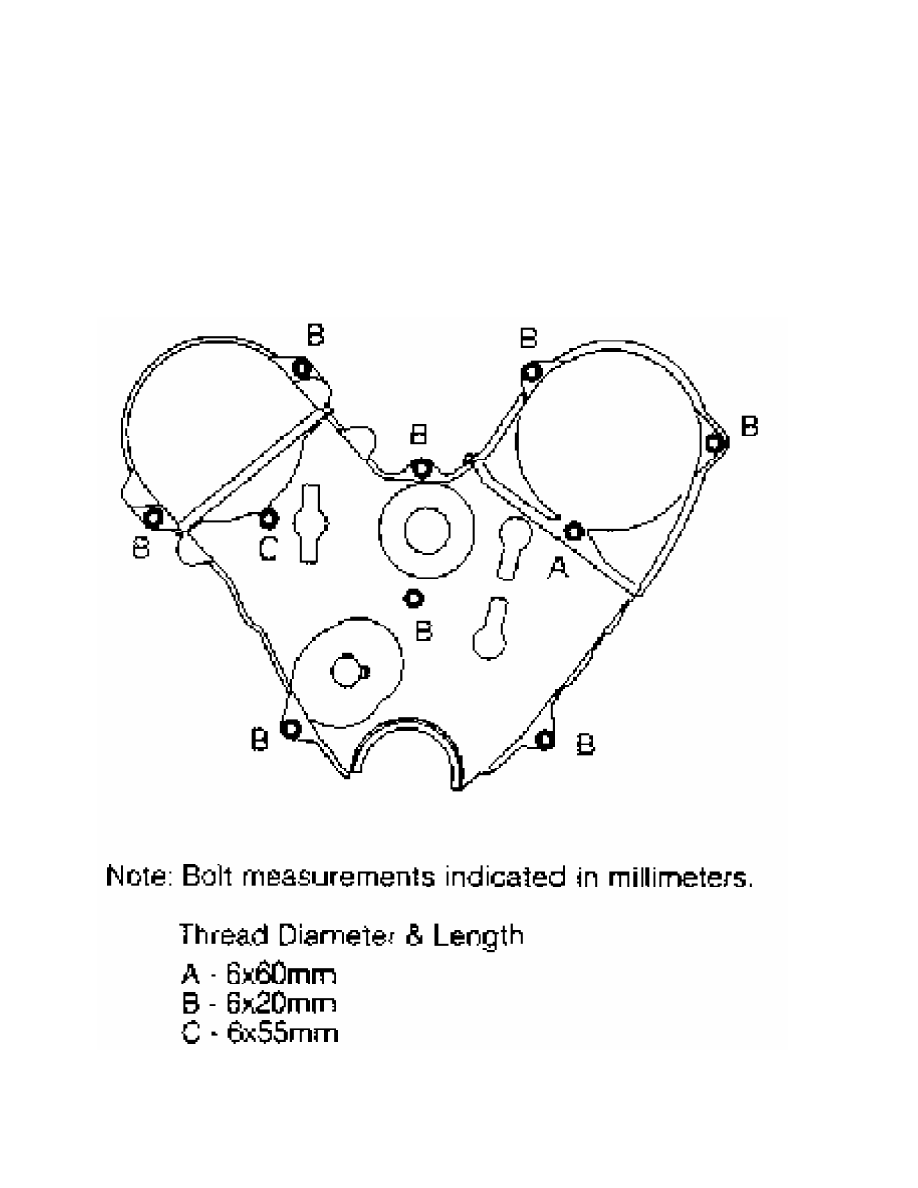

proper length bolts in timing belt covers. See Fig. 9. Tighten bolts

to specification. See TORQUE SPECIFICATIONS (MONTERO & PICKUP) table.

Fig. 9: Identifying Timing Belt Cover Bolt Lengths (MONTERO & PICKUP)

Courtesy of Mitsubishi Motor Sales of America, Inc.