Mitsubishi Galant (2004+). Manual - part 991

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-781

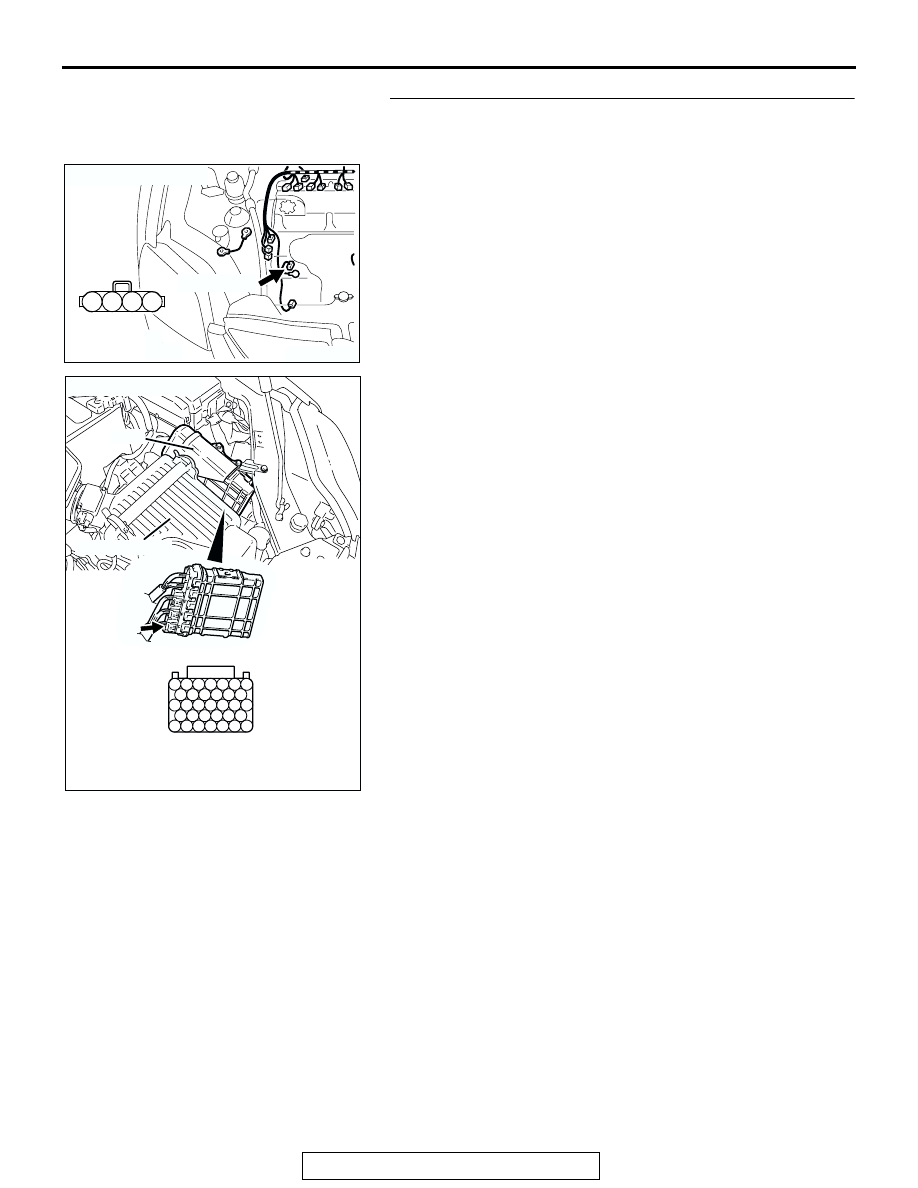

STEP 7. Check for harness damage between generator

connector B-116 (terminal No. 4) and PCM connector B-23

(terminal No. 131).

Q: Is the harness wire in good condition?

YES : Replace the generator. Then go to Step 8.

NO : Repair it. Then go to Step 8.

AK303884

2

1

3

4

AB

CONNECTOR: B-116

B-116 (GR)

HARNESS

CONNECTOR:

COMPONENT SIDE

127 126 125 124 123 122 121

133 132 131 130 129 128

140 139 138 137 136 135 134

146 145 144 143 142 141

153 152 151 150 149 148 147

AK303058

HARNESS CONNECTOR:

COMPONENT SIDE

CONNECTOR: B-23

B-23

PCM

AB

AIR CLEANER