Mitsubishi Galant (2004+). Manual - part 580

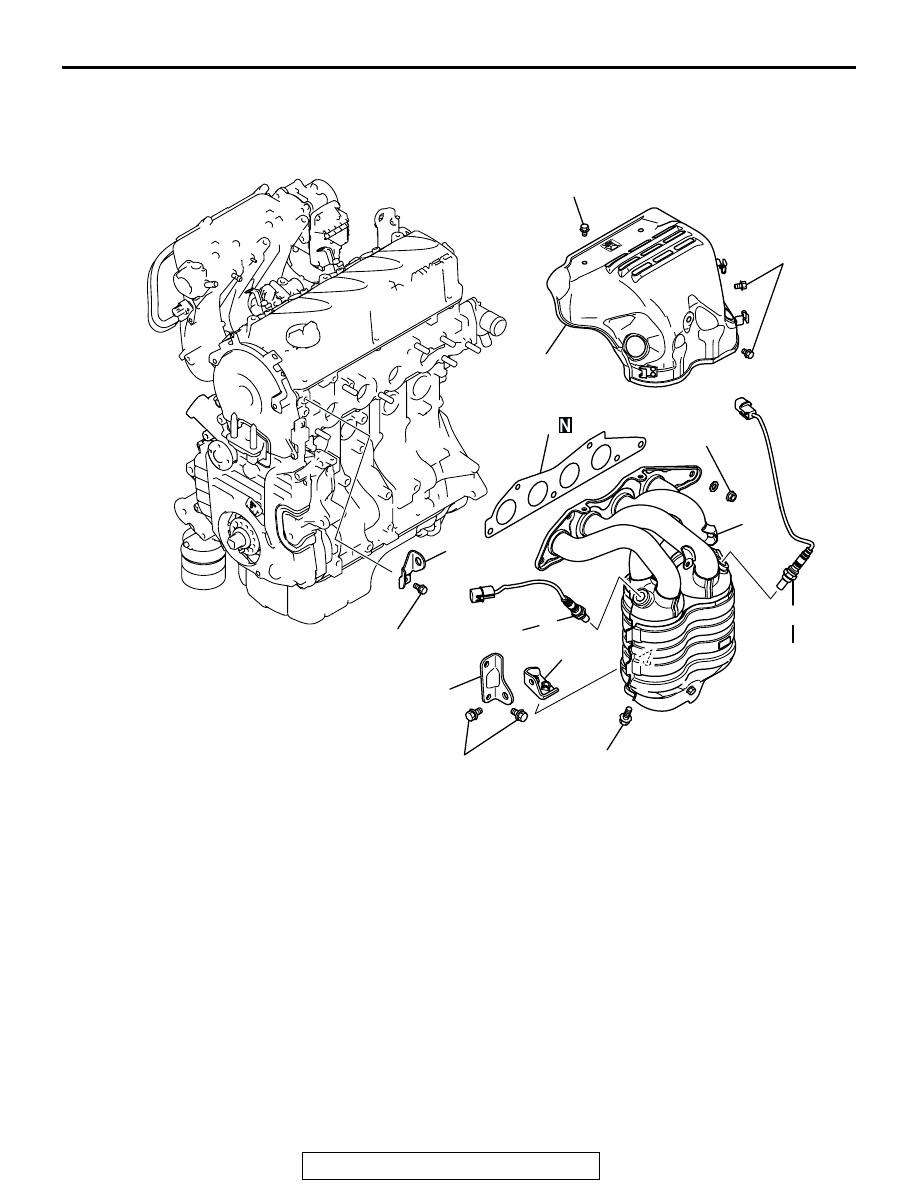

EXHAUST MANIFOLD

TSB Revision

ENGINE OVERHAUL <2.4L ENGINE>

11B-9

EXHAUST MANIFOLD

REMOVAL AND INSTALLATION

M1113004900457

Required Special Tools:

• MD998770: Oxygen Sensor Wrench

AK303212

1

2

3

4

8

5

6

7

34 ± 5 N·m

26 ± 2 ft-lb

36 ± 5 N·m

27 ± 3 ft-lb

44 ± 5 N·m

33 ± 3 ft-lb

49 ± 5 N·m

36 ± 3 ft-lb

14 ± 1 N·m

124 ± 8 in-lb

24 ± 3 N·m

18 ± 1 ft-lb

14 ± 1 N·m

124 ± 8 in-lb

44 ± 5 N·m

33 ± 3 ft-lb

AB

REMOVAL STEPS

1. ENGINE HANGER

<<A>> >>B<<

2. OXYGEN SENSOR

<<A>> >>B<<

3. OXYGEN SENSOR

4. EXHAUST MANIFOLD COVER

5. EXHAUST MANIFOLD BRACKET

"B"

6. EXHAUST MANIFOLD

7. EXHAUST MANIFOLD GASKET

8. EXHAUST MANIFOLD BRACKET

"A"

REMOVAL STEPS (Continued)