Content .. 1358 1359 1360 1361 ..

Mitsubishi Galant (2004+). Manual - part 1360

ON-VEHICLE SERVICE

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <3.8L ENGINE>

13B-1133

THROTTLE BODY (THROTTLE VALVE AREA)

CLEANING

M1131001000503

WARNING

If the throttle valve is operation in service, a finger

might be injured as the result of being caught by the

throttle valve. Make sure that the ignition switch is

surely in "LOCK"(OFF) position before the service in

order that the throttle valve cannot be operation.

1. Remove the throttle body.

CAUTION

• Do not spray the cleaning solvent directly to the throttle

valve.

• Make sure the cleaning solvent does not enter the

motor and the sensor through the shaft.

2. Spray cleaning solvent on a clean cloth.

3. Wipe off the dirt around the throttle valve with the cloth

sprayed with cleaning solvent.

4. Attach the throttle body.

FUEL PRESSURE TEST

M1131001900584

Required Special Tools:

• MB991958: Scan tool (MUT-III Sub Assembly)

• MB991824: V.C.I.

• MB991827: USB Cable

• MB991910: Main Harness A

• MB991637: Fuel Pressure Gauge Set

• MD998709: Adaptor Hose

• MD998742: Hose Adaptor

1. Release residual pressure from the fuel line to prevent fuel

spray. (Refer to

WARNING

To prevent a fire, cover the hose connection with

shop towels to prevent splashing of fuel that could be

caused by some residual pressure in the fuel pipe

line.

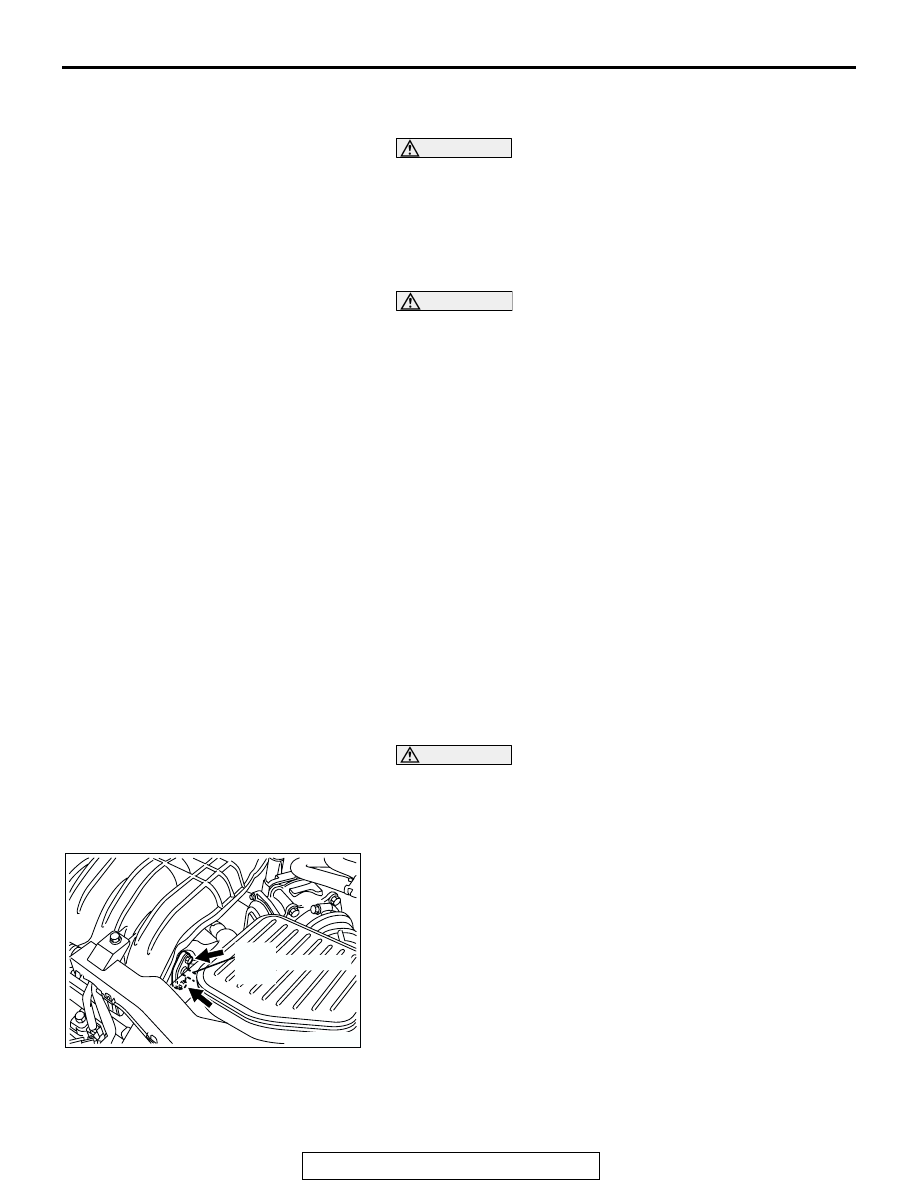

2. Disconnect the fuel high-pressure hose at the fuel rail side.

3. Assemble the fuel pressure measurement tools as follows.

AK203312AB

FUEL

HIGH-PRESSURE

HOSE