Content .. 1072 1073 1074 1075 ..

Mitsubishi Galant (2004+). Manual - part 1074

ON-VEHICLE SERVICE

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-1113

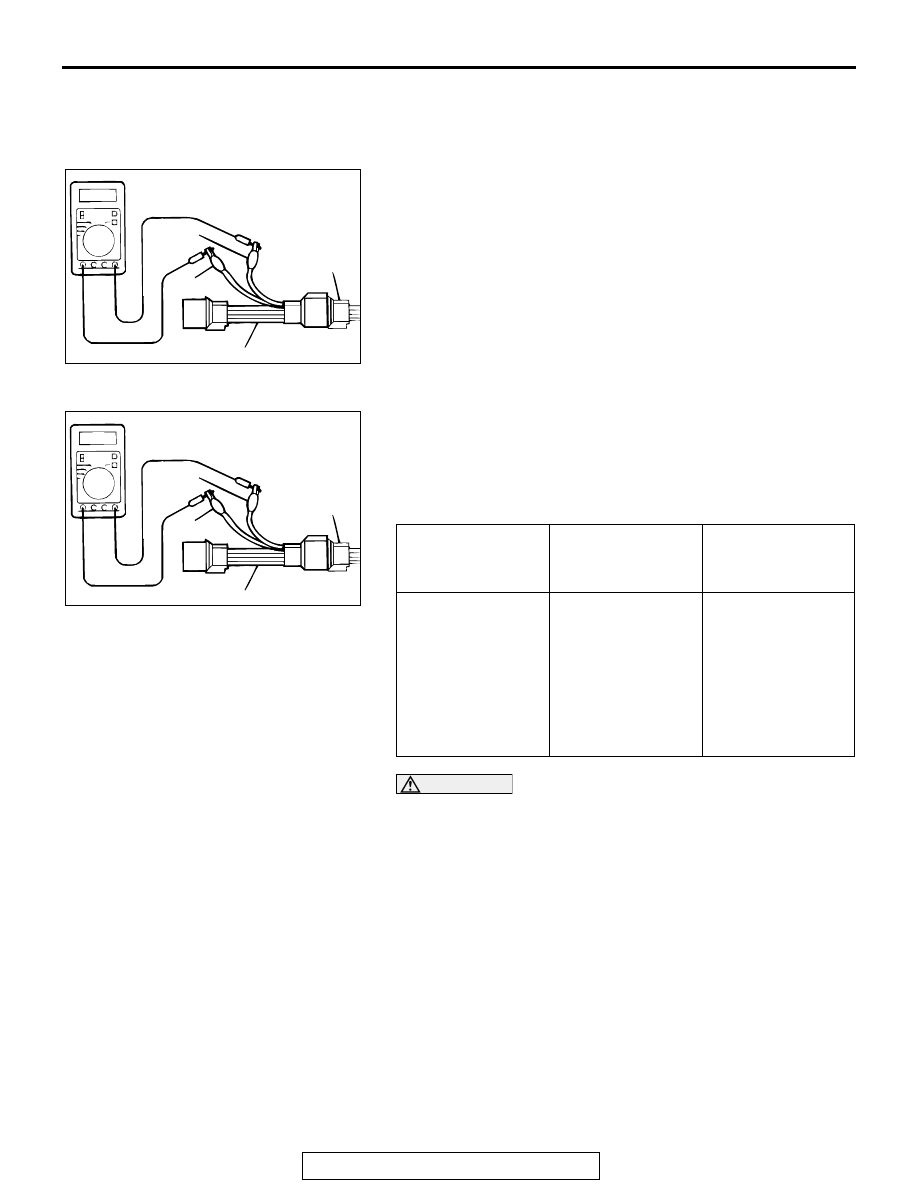

<Heated oxygen sensor (front)>

1. Using the scan tool MB991958, observe HO

2

S reading. If

values are unsatisfactory, or if Scan tool is not available, use

the following procedure:

(1) Disconnect the heated oxygen sensor connector and

connect special tool MB991316 to the connector on the

heated oxygen sensor side.

(2) Make sure that there is continuity [4.5

− 8.0 ohms at 20°C

(68

°F)] between terminal No. 1 (red clip) and terminal No.

3 (blue clip) on the heated oxygen sensor connector.

(3) If there is no continuity, replace the heated oxygen

sensor.

(4) Warm up the engine until engine coolant is 80

°C (176°F)

or higher.

(5) Perform a revving for 5 minutes or more with the engine

speed of 4,500 r/min.

(6) Connect a digital voltage meter between terminal No. 2

(black clip) and terminal No. 4 (white clip).

2. While repeatedly revving the engine, measure the heated

oxygen sensor output voltage.

Standard value:

CAUTION

• Be very careful when connecting the jumper wire;

incorrect connection can damage the heated oxygen

sensor.

• Be careful the heater is broken when voltage of beyond

8 volts is applied to the heated oxygen sensor heater.

NOTE: If the sufficiently high temperature [of approximate

400

°

C (752

°

F) or more] is not reached although the heated

oxygen sensor is normal, the output voltage would be possi-

bly low although the rich air/fuel ratio. Therefore, if the out-

put voltage is low, use jumper wires to connect the terminal

No. 1 (red clip) and the terminal No. 3 (blue clip) of the

heated oxygen sensor with a (+) terminal and (-) terminal of

8 volts power supply respectively, then check again.

3. If the output voltage is not within the standard value, replace

the heated oxygen sensor.

ENGINE

HEATED OXYGEN

SENSOR OUTPUT

VOLTAGE

REMARKS

When revving

engine

0.6

− 1.0 volt

If you make the

air/fuel ratio rich by

revving the engine

repeatedly, a

normal heated

oxygen sensor will

output a voltage of

0.6

− 1.0 volt.

AKX01624 AB

MB991316

HEATED

OXYGEN

SENSOR

EQUIPMENT

SIDE

CONNECTOR

BLUE

RED

AKX01624

HEATED

OXYGEN

SENSOR

COMPONENT

SIDE

CONNECTOR

MB991316

WHITE

BLACK

AN