Mitsubishi Galant (2004+). Manual - part 27

BOLTED PANEL FIT AND ADJUSTMENT

TSB Revision

REFERENCE MATERIAL

8-3

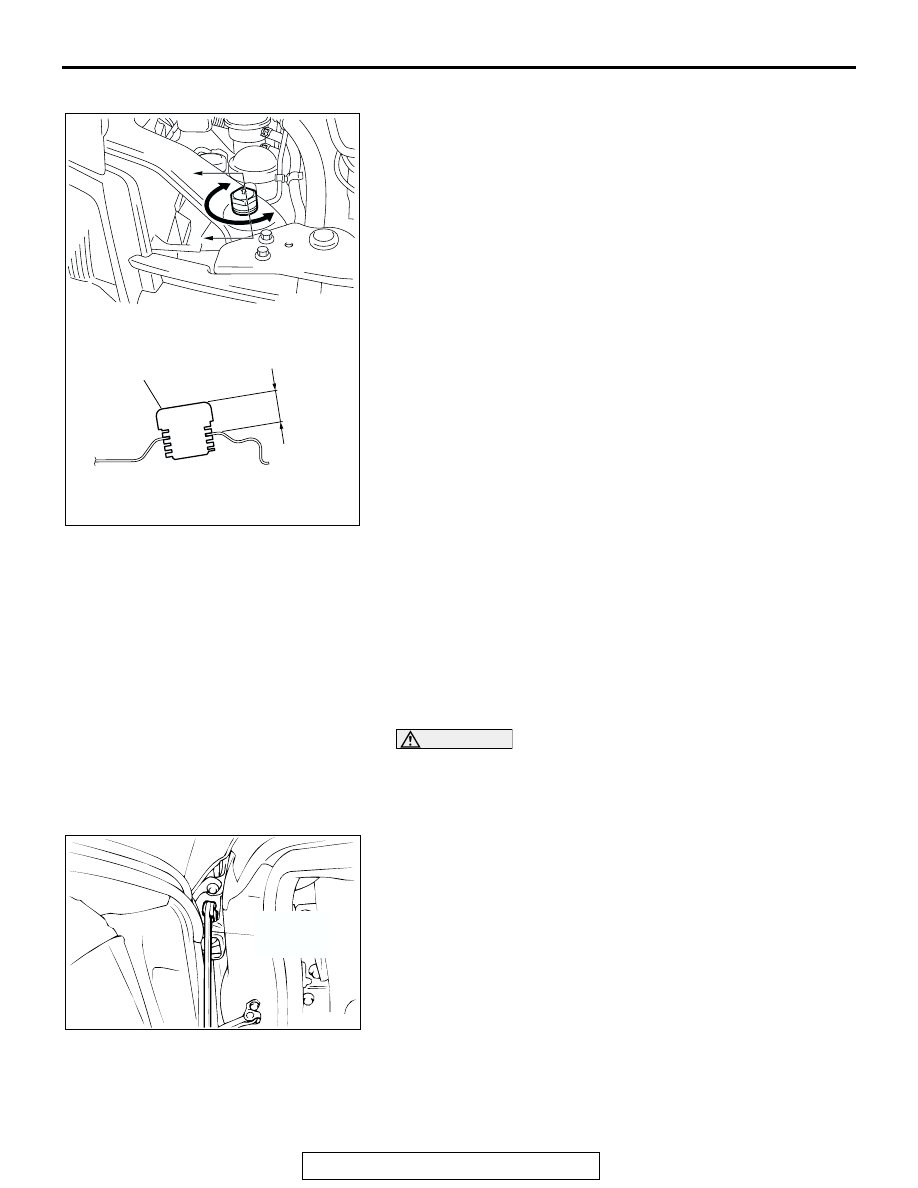

ADJUSTMENT OF HOOD HEIGHT

Turn the hood dumper until its height is as shown. If the hood

height is still not even at the left and right sides, turn the hood

dumper further until the hood height is even.

NOTE: Turning a new hood dumper one full turn will

increase/decrease the hood height by approximately 3 mm (0.1

inch).

DOOR

M4080006000160

ADJUSMENT OF DOOR FIT

Required Special Tools:

•

MB990211: Slide Hammer

•

MB990243: Body Puller

•

MB990900 or MB991164: Door adjusting Wrench

•

MB990939: Brass Bar

CAUTION

•

Attach protection tape to the fender and door edges

where the hinge is installed.

•

Do not rotate special tool MB991164 with a torque of

over 98 N

⋅

m (72 ft-lb).

1. Use special tool MB990900 or MB991164 to loosen the

hinge mounting bolts on the body side, and then adjust the

clearance around the door so that it is uniform on all sides.

Door hinge mounting bolt tightening torque: 27

±

5

N

⋅

m (20

±

4 ft-lb)

AC205081

AC205082

AC205810

SECTION A – A

A

A

HOOD DAMPER

AC

UNITS: mm (in)

17 ± 0.5

(0.7 ± 0.02)

AC000592

MB990900

OR

MB991164

AB