Mitsubishi Galant. Manual - part 510

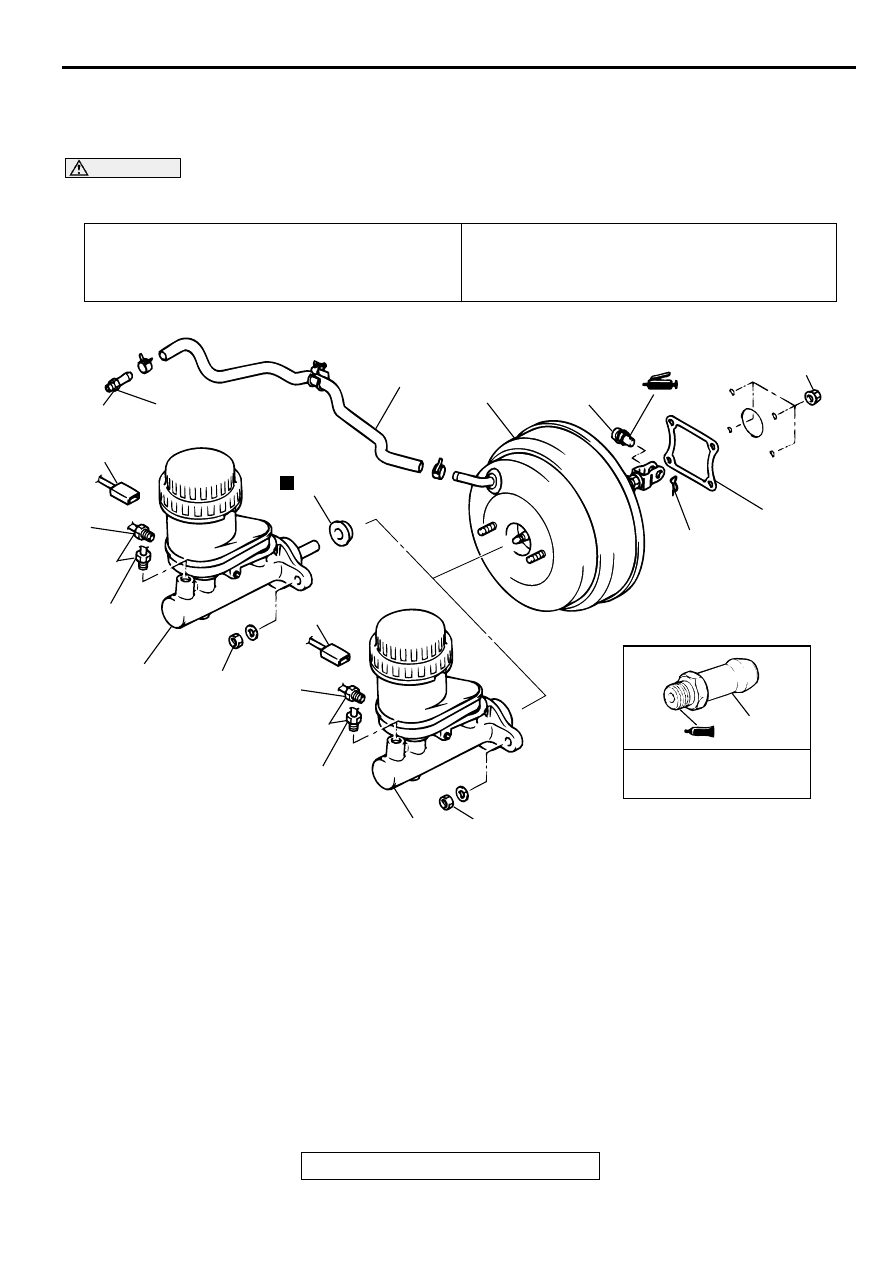

MASTER CYLINDER ASSEMBLY AND BRAKE BOOSTER

TSB Revision

BASIC BRAKE SYSTEM

35A-31

M A STER C YLIN DER ASSEM B LY AN D B R A K E B O O STER

REMOVAL AND INSTALLATION

M1351003700054

CAUTION

Do not remove the check valve from the vacuum hose. If the check valve is defective, replace it

together with the vacuum hose.

Pre-removal Operation

Brake Fluid Draining

Post-installation Operation

•

Brake Fluid Supplying

•

Brake Line Bleeding (Refer to

.)

•

Brake Pedal Adjustment (Refer to

.)

AC003755

13 N·m

113 in-lb

5

4

2

1

1

15 N·m

11 ft-lb

3

10

8

N

6

9

14 N·m

124 in-lb

10 N·m

89 in-lb

5

SEALANT: 3M™ AAD PART

NO. 8661, 8663, 8672, 8678,

8679 OR EQUIVALENT

AB

7

1

1

15 N·m

11 ft-lb

2

3

15 - 18 N·m

11 - 13 ft-lb

<VEHICLES WITH TCL>

<VEHICLES WITHOUT TCL>

REMOVAL STEPS

1. BRAKE TUBE CONNECTION

2. BRAKE FLUID LEVEL SENSOR

CONNECTOR

3. MASTER CYLINDER ASSEMBLY

>>B<<

•

ADJUSTMENT OF CLEARANCE BE-

TWEEN BRAKE BOOSTER PUSH-

ROD AND PRIMARY PISTON

>>A<<

4. VACUUM HOSE (WITH BUILT-IN

CHECK VALVE)

5. FITTING

6. SNAP PIN

7. CLEVIS PIN

8. BRAKE BOOSTER

9. SEALER

10. PLATE AND SEAL ASSEMBLY <VE-

HICLES WITH TCL>

REMOVAL STEPS (Continued)