Mitsubishi Galant. Manual - part 326

THROTTLE BODY ASSEMBLY

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <3.0L>

13B-529

3. If it dose not turn smoothly, the O-ring may be trapped,

remove the item, re-install it into the fuel rail and check

again.

4. Tighten the fuel pressure regulator and high-pressure fuel

hose to the specified torque.

Tightening torque:

8.8 N

⋅⋅⋅⋅

m (78 in-lb) <Fuel pressure regulator>

4.9 N

⋅⋅⋅⋅

m (43 in-lb) <High-pressure fuel hose>

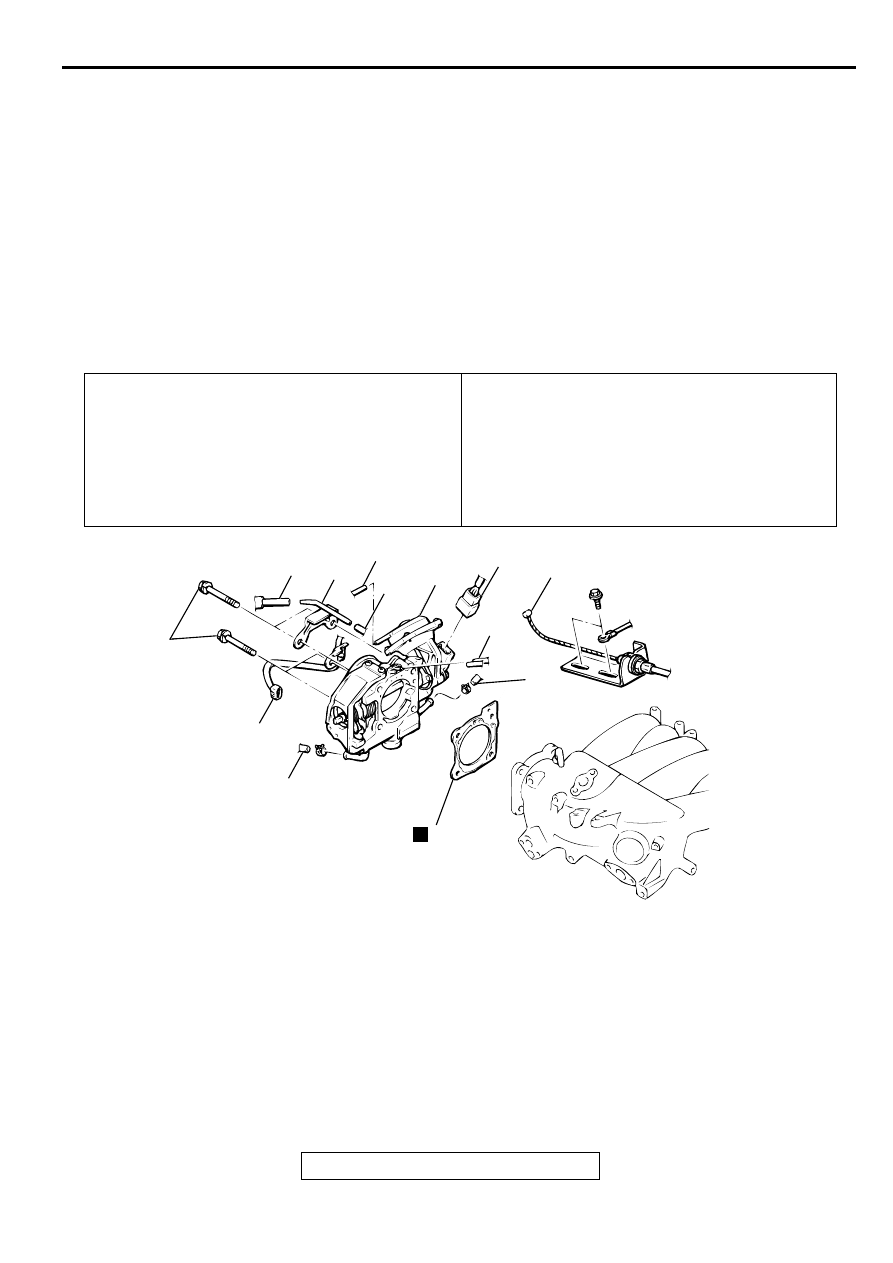

TH R O TTLE B O D Y A SSEM B LY

REMOVAL AND INSTALLATION

M1131007700102

Pre-removal Operation

•

Engine Coolant Draining [Refer to GROUP 00,

Maintenance Service

−

Engine Coolant (Change)

•

Air Cleaner Removal (Refer to GROUP 15, Air

Cleaner

Post-installation Operation

•

Air Cleaner Installation (Refer to GROUP 15, Air

Cleaner

.)

•

Engine Coolant Refilling [Refer to GROUP 00,

Maintenance Service

−

Engine Coolant (Change)

.]

•

Accelerator Cable Adjustment (Refer to GROUP 17, On-

vehicle Service

−

Accelerator Cable Check and

Adjustment

AC001624

4

6

4

4

7

2

1

4

3

5

5

8

19 N·m

14 ft-lb

AC

N

REMOVAL STEPS

1.

ACCELERATOR CABLE

CONNECTION

2.

THROTTLE POSITION SENSOR

CONNECTOR

3.

IDLE AIR CONTROL MOTOR

CONNECTOR

4.

VACUUM HOSE CONNECTION

5.

WATER HOSE CONNECTION

6.

VACUUM PIPE CONNECTION

7.

THROTTLE BODY

>>A<<

8.

THROTTLE BODY GASKET

REMOVAL STEPS (Continued)