Mitsubishi Galant 9G. Manual - part 920

ON-VEHICLE SERVICE

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-1122

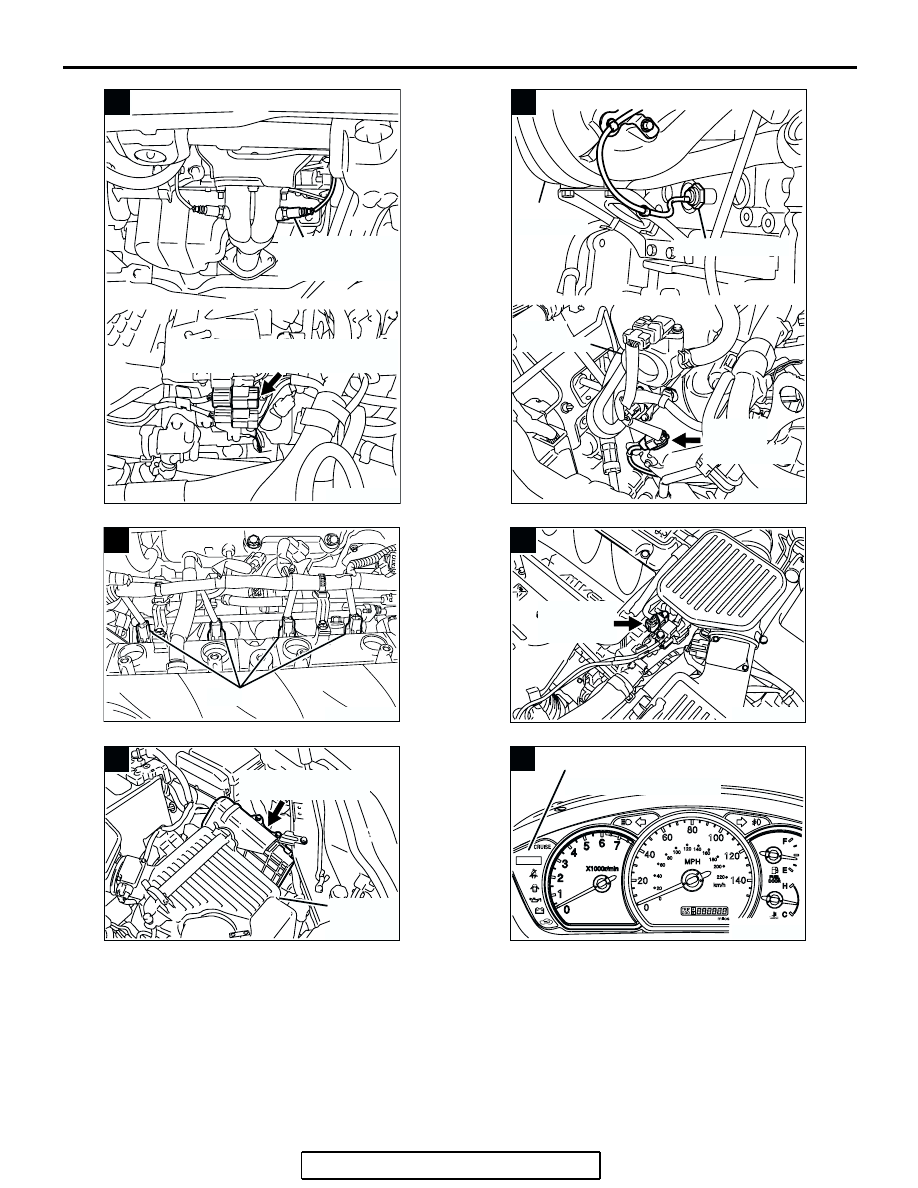

AK303957AB

CYLINDER 2, 3

HEATED OXYGEN

SENSOR (REAR)

CYLINDER 2, 3 HEATED OXYGEN

SENSOR (REAR) CONNECTOR

L

AK303958AB

KNOCK SENSOR

INTAKE

MANIFOLD

INTAKE

MANIFOLD

M

KNOCK

SENSOR

CONNECTOR

AK303959AB

N

INJECTOR

AK303960AB

CAMSHAFT

POSITION

SENSOR

O

AK303961AB

POWERTRAIN

CONTROL MODULE

P

AIR

CLEANER

AK302202AC

Q

MULFUNCTION INDICATOR LAMP

(SERVICE ENGINE SOON OR

CHECK ENGINE LAMP)