Mitsubishi Galant 9G. Manual - part 595

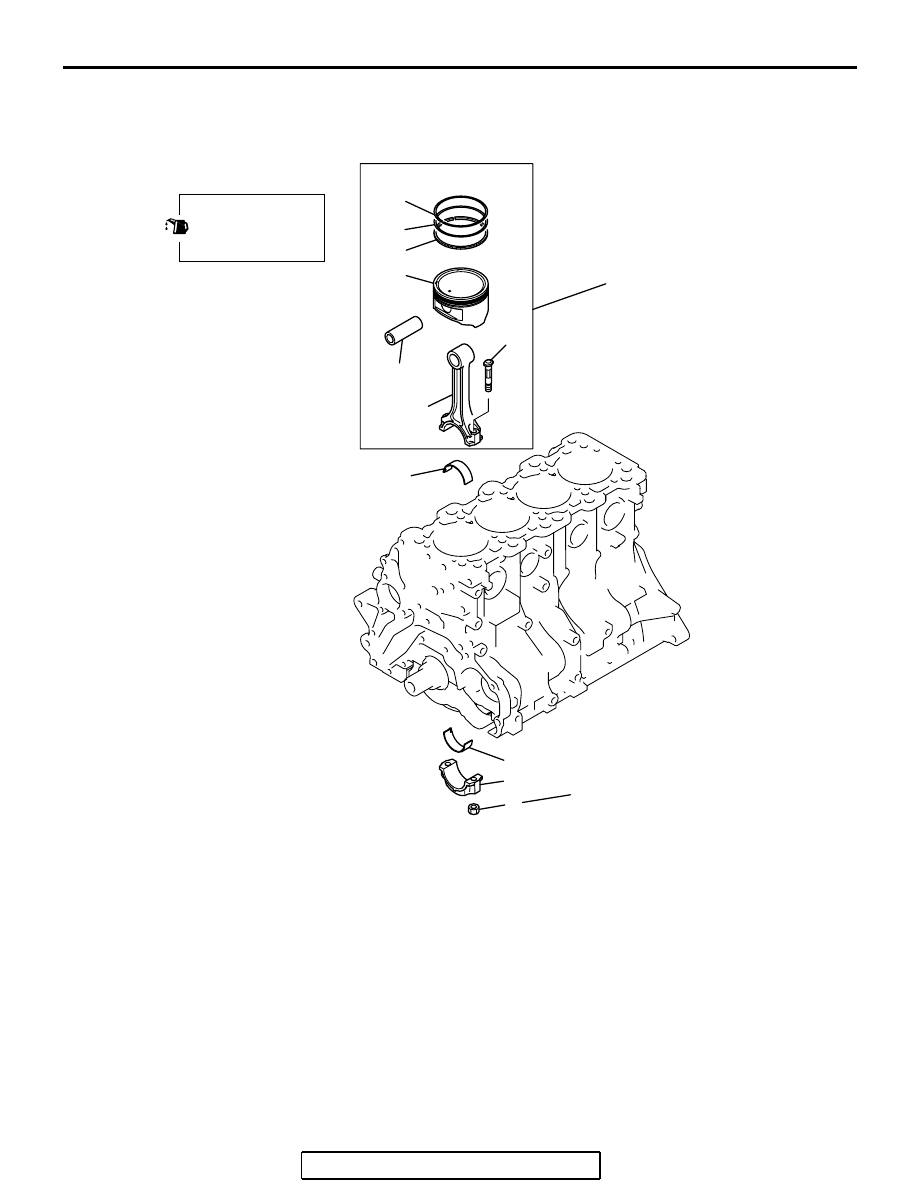

PISTON AND CONNECTING ROD

TSB Revision

ENGINE OVERHAUL <2.4L ENGINE>

11B-52

PISTON AND CONNECTING ROD

REMOVAL AND INSTALLATION

M1113008400584

Required Special Tool:

• MIT216941: Piston Pin Setting Tool

AK301260AC

1

2

3

4

5

6

7

8

9

10

11

12

20 ± 2 N·m

15 ± 1 ft-lb

APPLY ENGINE OIL

TO ALL MOVING

PARTS BEFORE

INSTALLATION.

→ + 90˚ to 94˚

REMOVAL STEPS

>>G<<

1. NUT

2. CONNECTING ROD CAP

>>D<<

3. CONNECTING ROD BEARING

>>E<<

4. PISTON AND CONNECTING ROD

ASSEMBLY

>>D<<

5. CONNECTING ROD BEARING

>>C<<

6. PISTON RING No. 1

>>C<<

7. PISTON RING No. 2

>>B<<

8. OIL RING

9. PISTON PIN

10.PISTON

11. CONNECTING ROD

12.BOLT

REMOVAL STEPS (Continued)