Mitsubishi Galant 9G. Manual - part 592

CYLINDER HEAD AND VALVES

TSB Revision

ENGINE OVERHAUL <2.4L ENGINE>

11B-40

3. Before fitting the valve seat, either heat the cylinder head up

to approximately 250

°C (482°F) or cool the valve seat in

liquid nitrogen, to prevent the cylinder head bore from

galling.

4. Using a valve seat cutter, correct the valve seat to the

specified width and angle.

See "VALVE SEAT RECONDITIONING PROCEDURE" on

the previous page.

VALVE GUIDE REPLACEMENT PROCEDURE

1. Using a press, remove the valve guide toward the cylinder

block.

CAUTION

Do not install a valve guide of the same size again.

2. Rebore the valve guide hole of the cylinder head so that it

fits the press-fitted oversize valve guide.

Valve guide hole diameters

0.05 oversize 11.05

− 11.07 mm (0.4350 − 0.4358 inch)

0.25 oversize 11.25

− 11.27 mm (0.4429 − 0.4437 inch)

0.50 oversize 11.50

− 11.52 mm (0.4528 − 0.4535 inch)

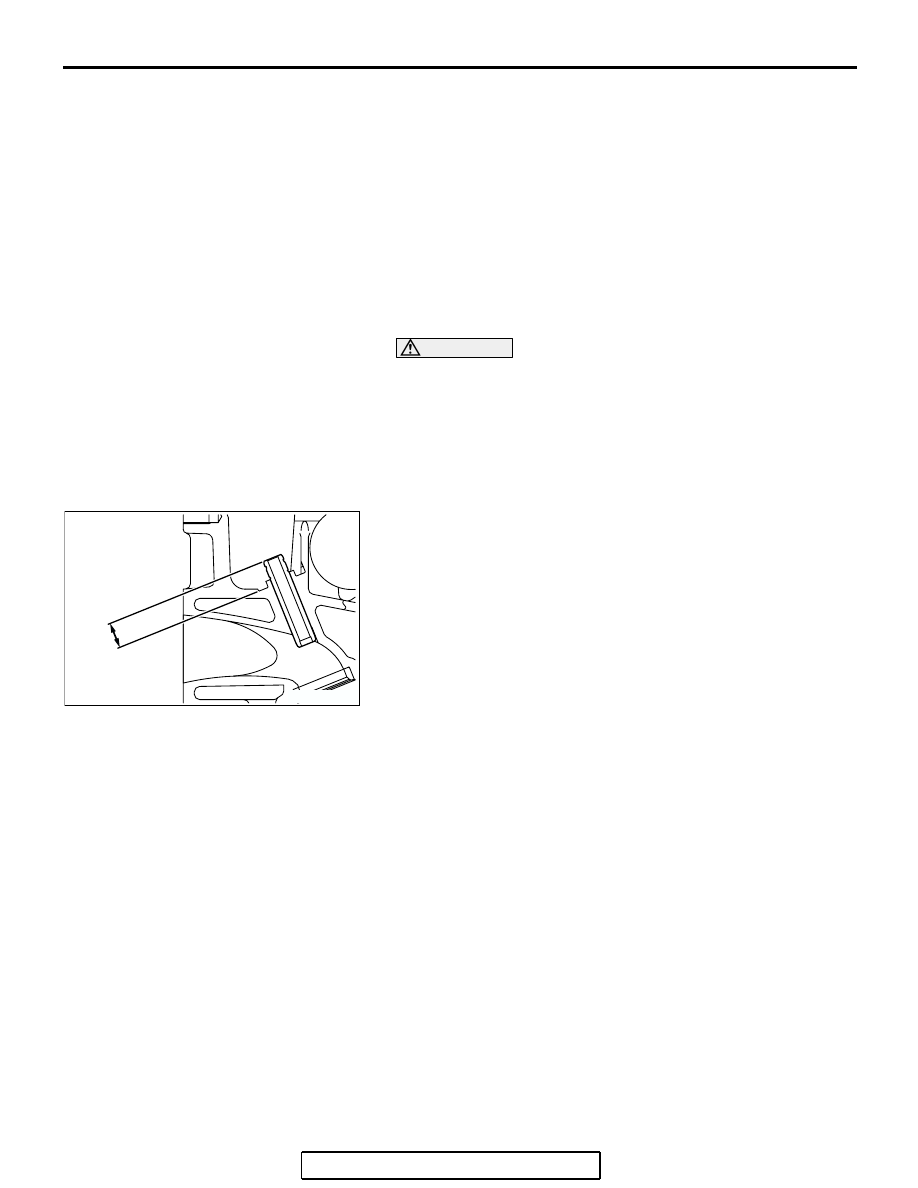

3. Press-fit the valve guide until it protrudes 14.0 mm (0.55

inch) from the cylinder head top surface as shown in the

illustration.

NOTE: When press-fitting the valve guide, work from the

cylinder head top surface.

NOTE: Pay attention to the difference in length of the valve

guides. [Intake side: 45.5 mm (1.79 inches); exhaust side:

50.5 mm (1.99 inches)]

NOTE: After installing the valve guides, insert new valves in

them to check for smooth operation.

AK301399AC

14.0 mm

(0.55 in)