Mitsubishi Galant 9G. Manual - part 422

PRECAUTIONS BEFORE SERVICE

TSB Revision

GENERAL

00-26

CAUTION

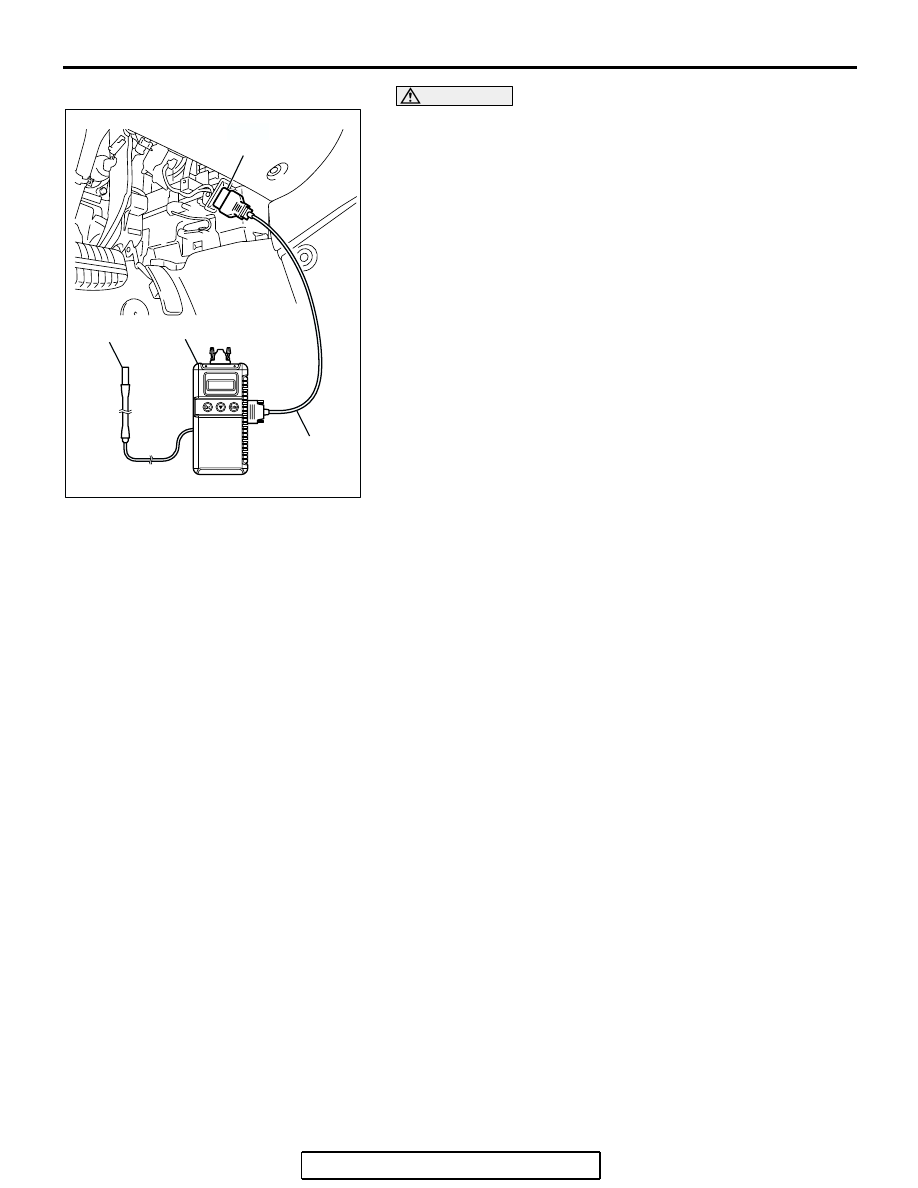

To prevent damage to scan tool MB991958, always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting scan tool MB991958.

1. Connect scan tool MB991958 to the data link connector.

2. Turn the ignition switch to the "ON" position.

3. Select "Check Mode" form the menu screen.

4. Select "ERASE MEMORY" form the menu screen.

5. Initialize the learning value.

6. After initialization of the learning value, learn the idling in

MFI engine. (Refer to LEARNING PROCEDURE FOR

IDLING IN MFI ENGINE).

LEARNING PROCEDURE FOR IDLING IN MFI

ENGINE

M1001011800102

PURPOSE

When the PCM is replaced, or when the learning value is initial-

ized, the idling is not stabilized because the learning value in

MFI engine is not completed. In this case, carry out the learning

method for the idling through the following procedures.

LEARNING PROCEDURE

1. Start the engine and carry out the warm-up for the engine

coolant temperature to reach 80

°C or more.

NOTE: When the engine coolant temperature is 80

°

C or

more, the warm-up is not needed if the ignition switch is in

"ON" position once.

2. Place the ignition switch in "LOCK" (OFF) position and stop

the engine.

3. After 10 seconds or more, start the engine again.

4. For 10 minutes, carry out the idling under the condition

shown below and then confirm the engine has the normal

idling.

• Transaxle: "P" range

• Operation in ignition-related, fan and attachments: Not to be

operated

• Engine coolant temperature: 80°C or more

NOTE: When the engine stalls during the idling, check the

dirtiness (on the throttle valve) of the throttle body and then

perform the service from Procedure 1 again.

AC302077

AC305412

AC306958AB

MB991824

MB991910

MB991668

DATA LINK

CONNECTOR