Mitsubishi Galant 9G. Manual - part 359

STARTING SYSTEM

TSB Revision

ENGINE ELECTRICAL

16-32

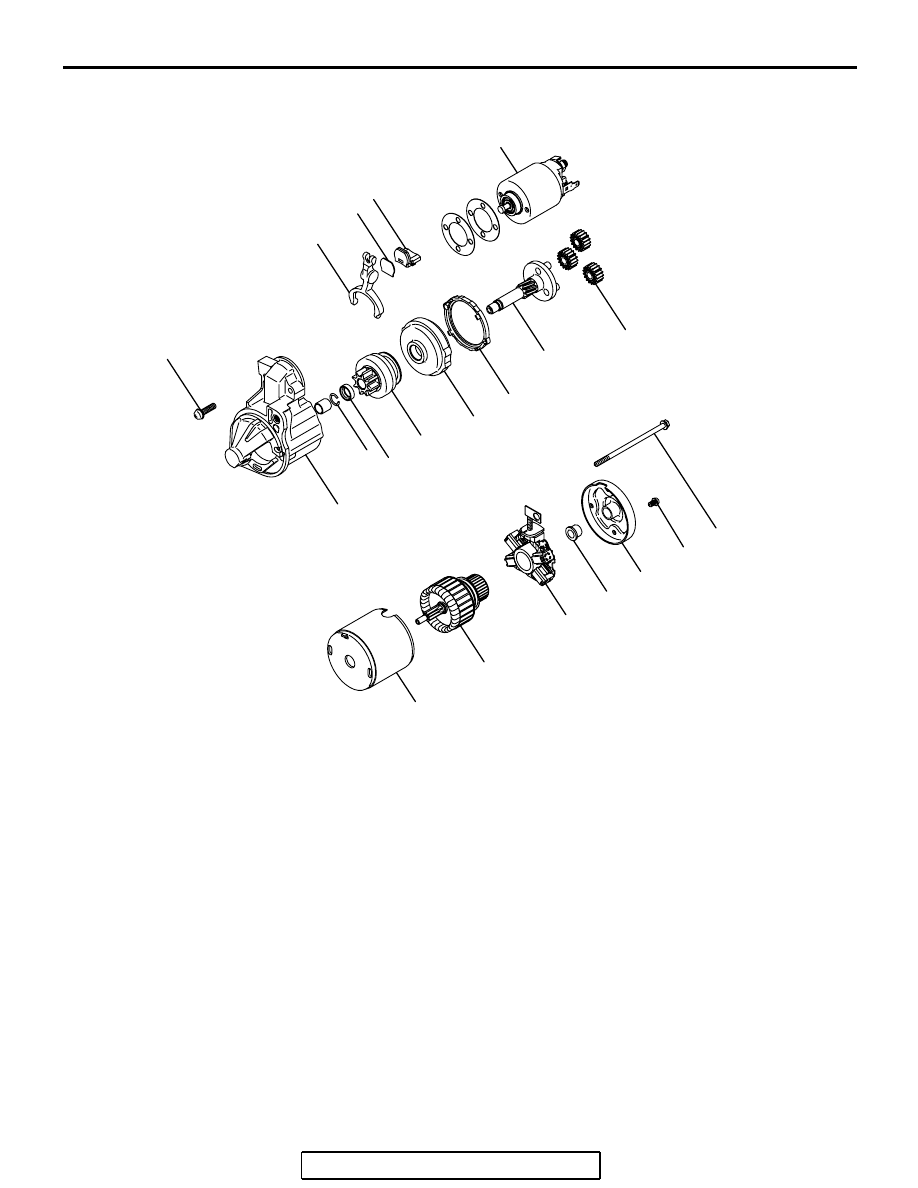

DISASSEMBLY AND ASSEMBLY

M1162001200150

AK204336AB

1

2

18

19

10

11

12

13

14

15 16

17

20

3

4

5

6

7

8

9

DISASSEMBLY STEPS

1. SCREW

2. MAGNETIC SWITCH

3. SCREW

4. SCREW

5. REAR BRACKET

6. BRUSH

7. REAR BEARING

8. ARMATURE

9. YOKE ASSEMBLY

10. PACKING A

11. PACKING B

12. PLATE

13. PLANETARY GEAR

14. LEVER

15. SNAP RING

16. STOP RING

17. OVERRUNNING CLUTCH

18. INTERNAL GEAR

19. PLANETARY GEAR HOLDER

20. FRONT BRACKET

DISASSEMBLY STEPS