Mitsubishi Galant 9G. Manual - part 333

CYLINDER HEAD GASKET

TSB Revision

ENGINE MECHANICAL <2.4L ENGINE>

11A-48

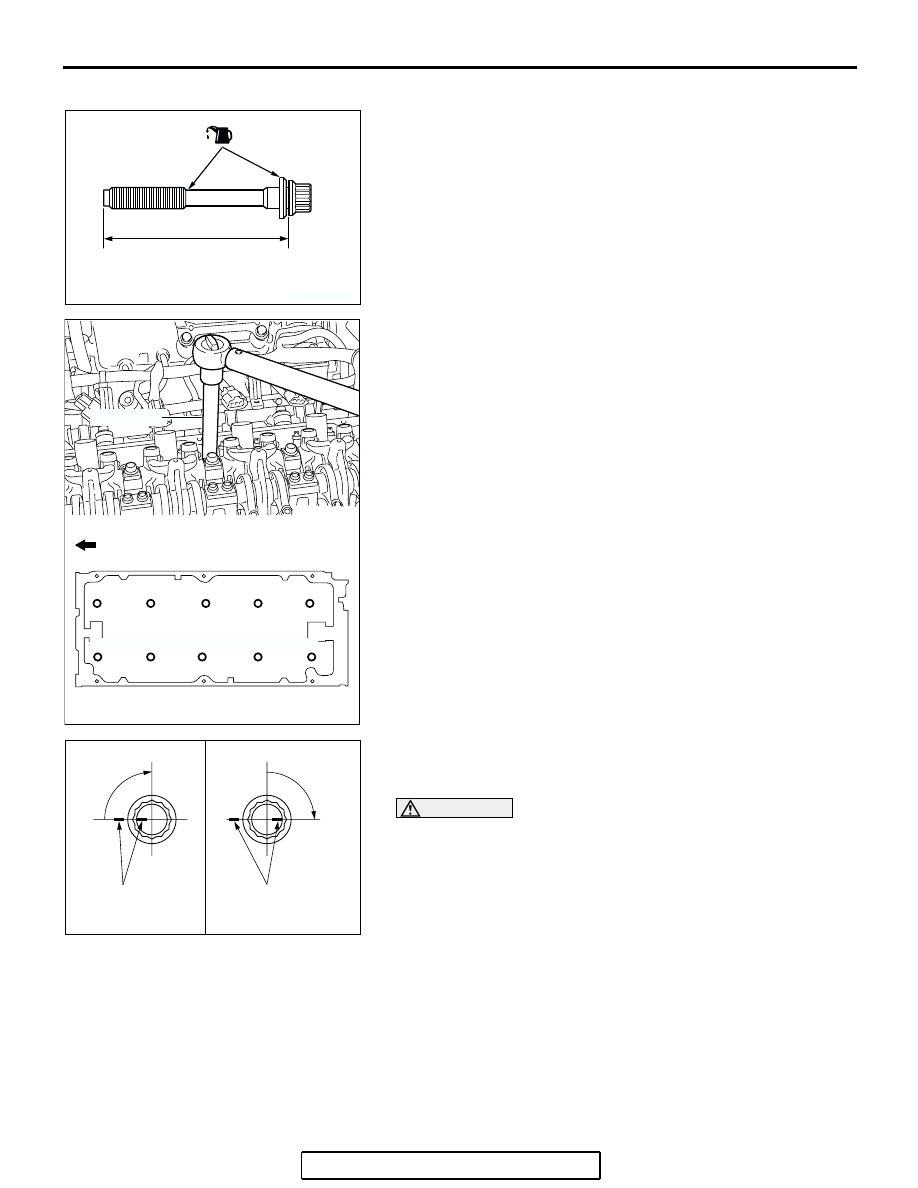

>>B<< CYLINDER HEAD BOLTS INSTALLATION

1. Check that the nominal length of each cylinder head bolt

meets the limit. If it exceeds the limit, replace the bolts with a

new one.

Limit (A): 99.4 mm (3.91 inches)

2. Apply a small amount of engine oil to the thread of the bolts

and to the washers.

3. Use special tool MB991654 to tighten the cylinder head

bolts in the following procedures.

(1) Tighten the bolts to 78

± 2 N⋅m (58 ± 1 ft-lb) in the order

shown.

(2) Loosen the bolts fully in the reverse sequence to that

shown.

(3) Tighten the bolts to 20

± 2 N⋅m (15 ± 1 ft-lb) in the order

shown.

(4) Apply a paint mark to the heads of the cylinder head bolts

and cylinder head, then tighten 90 degree angle as

shown.

CAUTION

• The bolt is not tightening sufficiently if the tightening

angle is less than a 90 degree angle.

• If the tightening angle exceeds the standard specifica-

tion, remove the bolt and start over from step 1.

(5) Tighten in a 90 degree angle as shown in the instructions

of the figure, then check to see that the paint mark on the

head of the cylinder head bolts and the paint mark on the

cylinder head is on a linear line.

.

AC102537

A

AC

(ENGINE OIL)

AC301456AB

ENGINE FRONT

MB991654

10

9

7

5

2

4

8

6

1

3

AC102331AB

PAINT MARKING

90˚

90˚

PAINT MARKING

STEP (4)

STEP (5)