Mitsubishi Galant 9G. Manual - part 301

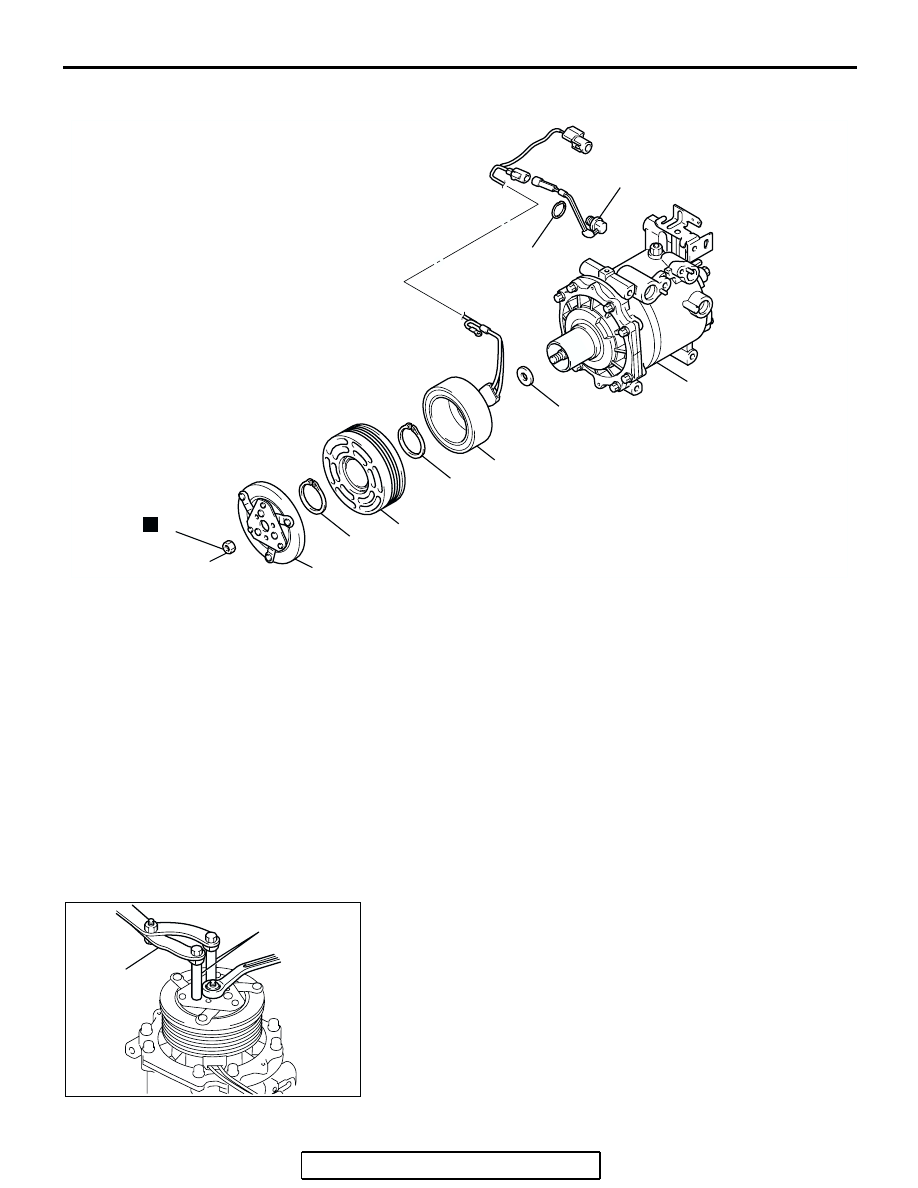

COMPRESSOR ASSEMBLY AND TENSION PULLEY

TSB Revision

HEATER, AIR CONDITIONING AND VENTILATION

55A-280

DISASSEMBLY AND ASSEMBLY

M1552004600659

Required Special Tools:

• MB991367: Special Spanner

• MB991386: Pin

DISASSEMBLY SERVICE POINT

.

<<A>> SELF-LOCKING NUT REMOVAL

AC209643AB

2

1

10

9

8

7

6

5

4

N

16 ± 1 N·m

12 ± 1 ft-lb

3

COOLING TEMPERATURE

SWITCH DISASSEMBLY STEPS

1.

SNAP RING

2.

COOLING TEMPERATURE

SWITCH

AIR CONDITIONING

COMPRESSOR CLUTCH

DISASSEMBLY

>>D<<

•

AIR GAP ADJUSTMENT

3.

SELF-LOCKING NUT

4.

ARMATURE

5.

SHIM

>>B<<

6.

SNAP RING

7.

ROTOR

8.

SNAP RING

>>A<<

9.

FIELD CORE

10. A/C COMPRESSOR

AIR CONDITIONING

COMPRESSOR CLUTCH

DISASSEMBLY (Continued)

AC209645AB

MB991386

MB991367