Mitsubishi Pajero Pinin. Manual - part 365

HEATER, AIR CONDITIONER AND VENTILATION

–

On-vehicle Service

55-11

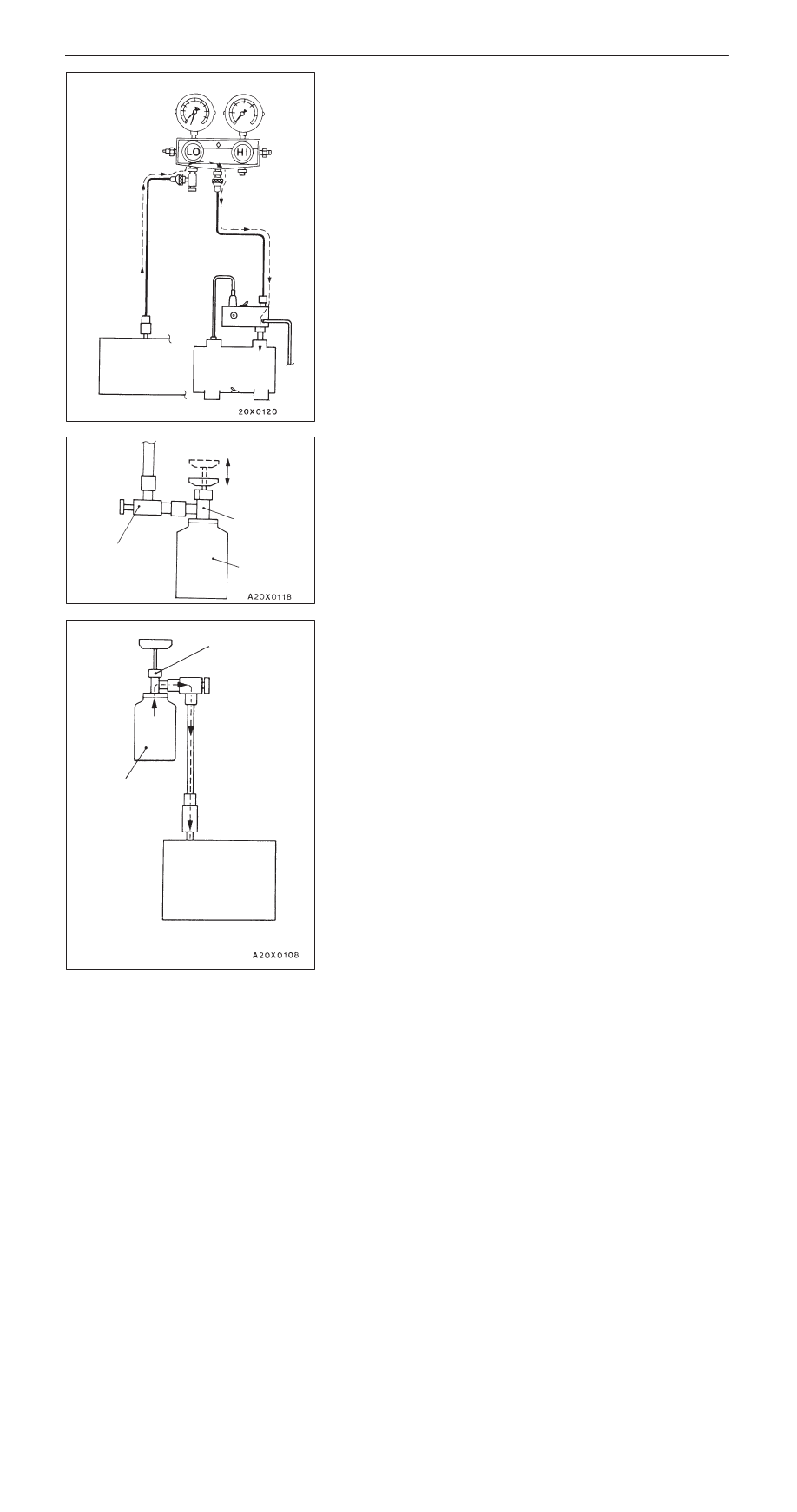

12. Turn the vacuum pump adaptor switch to the R-134a side

to start the vacuum pump.

Caution

Do not operate the compressor for evacuation.

13. Evacuate to a vacuum reading of 100 kPa or higher (takes

approx. 10 minutes).

14. Turn the vacuum pump adaptor switch OFF and allow

to stand it for 5 minutes.

Caution

Do not operate the compressor in the vacuum

condition; damage may occur.

15. Carry out a leak test. (Good if the negative pressure does

not drop.)

Caution

If the negative pressure drops, increase the tightness

of the connections, and then repeat the evacuation

procedure from step (12).

16. With the handle turned back all the way (valve open),

install the charging valve to the service can.

17. Turn the handle of the adaptor valve back all the way

(valve closed), remove it from the gauge manifold and

install the service can.

18. Tighten the handle of the charging valve (valve closed)

to puncture the service can.

19. Turn the handle of the charging valve back (valve open) and

tighten the handle of the adaptor valve (valve open) to

charge the system with refrigerant.

Caution

If the service can is inverted, liquid refrigerant may

be drawn into the compressor damaging it by liquid

compression. Keep the service can upright to ensure

that refrigerant is charged in gas state.

20. If the refrigerant is not drawn in, turn the handle of the

adaptor valve back all the way (valve closed).

21. Check for gas leaks using a leak detector.

If a gas leak is detected, re-tighten the connections, and

then repeat the charging procedure from evacuation in

step (12).

Caution

The leak detector for R-134a should be used.

22. Start the engine.

23. Operate the A/C and set to the lowest temperature (MAX.

COOL).

Low-pressure

service valve

Vacuum pump

Adaptor valve

Valve open

Valve close

Charging

valve

Service can

Charging valve

Service can

(Refrigerant

container)

Low-pressure

service valve