Mitsubishi Pajero Pinin. Manual - part 271

BODY –

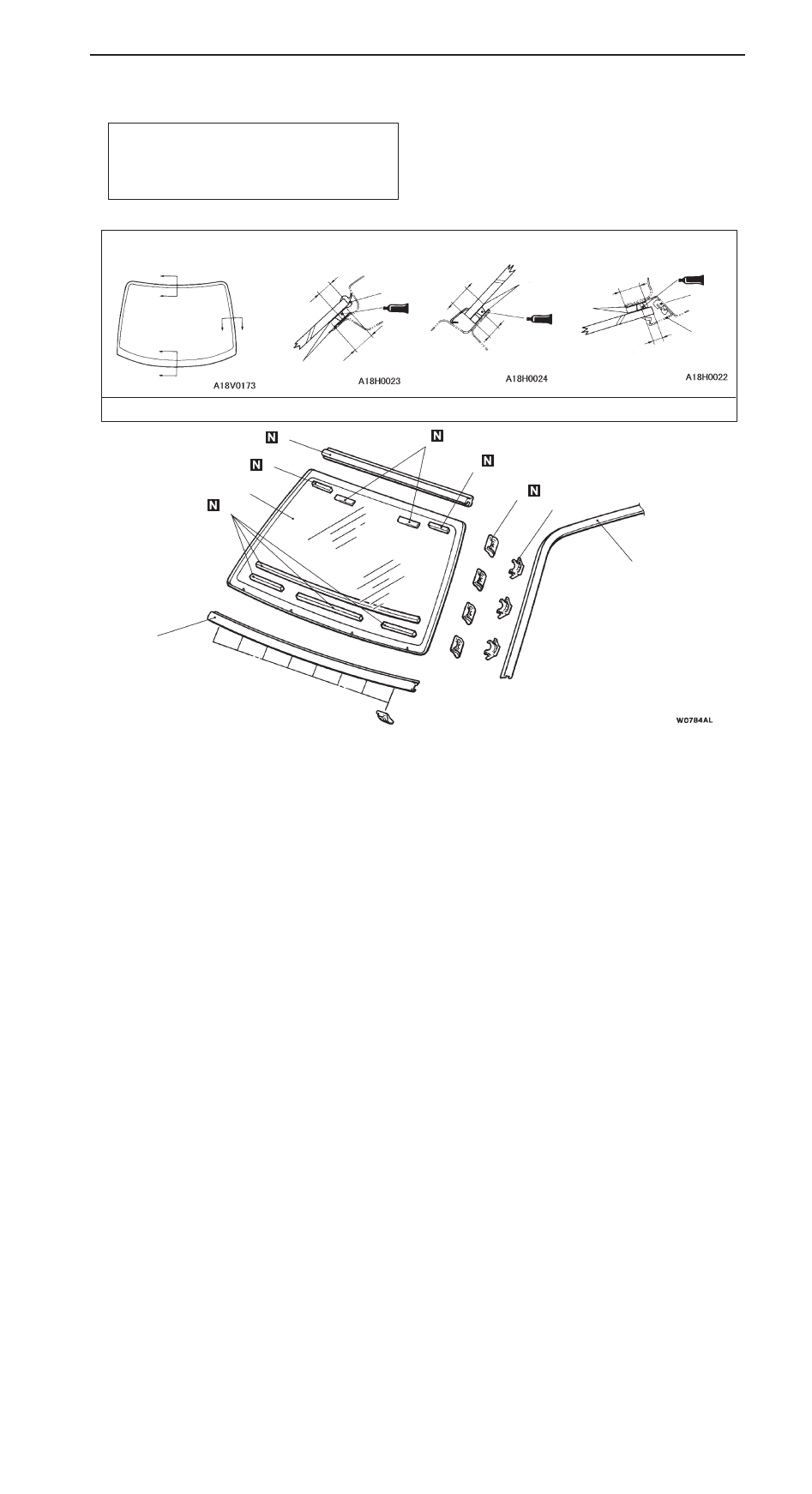

Window Glass

42-10

WINDSHIELD

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operations

D

Front Pillar Trim Removal and Installation

(Refer to GROUP 52A.)

D

Headlining Removal and Installation

(Refer to GROUP 52A.)

A

B

Adhesive: 3M ATD Part No. 8609 Super Fast Urethane Auto Glass Sealant or equivalent

A

B

C

C

Section A – A

Section B – B

Section C – C

mm

Primer

Primer

Primer

14

15

15

15

7

9

5

4

7

8

1

2

3

6

5

5

6

1

7

Removal steps

A

A

"

1. Roof drip moulding (Refer to

GROUP 51.)

2. Roof drip moulding clip

3. Windshield lower moulding

A

B

" "

A

A

4. Windshield

"

A

A

5. Windshield spacer

"

A

A

6. Windshield upper moulding

"

A

A

7. Clip

"

A

A

8. Glass stopper