Mitsubishi Pajero Pinin. Manual - part 249

ABS <4WD> –

Troubleshooting

35B-19

DATA LIST REFERENCE TABLE

The following items can be read by the MUT-

II

from the ABS-ECU input data.

1.

When the system is normal

Item No.

Check item

Checking requirements

Normal value

11

Front-right wheel speed sensor

Perform a test run

Vehicle speeds

displayed on the

12

Front-left wheel speed sensor

displayed on the

speedometer

and MUT

II

are

13

Rear-right wheel speed sensor

and MUT-

II

are

identical.

14

Rear-left wheel speed sensor

16

ABS-ECU power supply

voltage

Ignition switch: ON

9.2 – 17.5 V

32

G sensor

Vehicle is stopped.

2.4 – 2.6 V

Vehicle is running.

0.5 – 4.5 V

33

Stop lamp switch

Depress the brake pedal.

ON

Release the brake pedal.

OFF

2.

When the ABS-ECU shut off ABS operation.

When the diagnosis system stops the ABS-ECU, the MUT-

II

display data will be unreliable.

ACTUATOR TEST REFERENCE TABLE

The MUT-

II

activates the following actuators for testing.

NOTE

1.

If the ABS-ECU runs down, actuator testing cannot be carried out.

2.

Actuator testing is only possible when the vehicle is stationary.

ACTUATOR TEST SPECIFICATIONS

No.

Item

01

Solenoid valve for

front-right wheel

Solenoid valves and pump

motors in the hydraulic unit

(simple inspection mode)

02

Solenoid valve for front-left

wheel

(simple inspection mode)

03

Solenoid valve for rear-right

wheel

04

Solenoid valve for rear-left

wheel

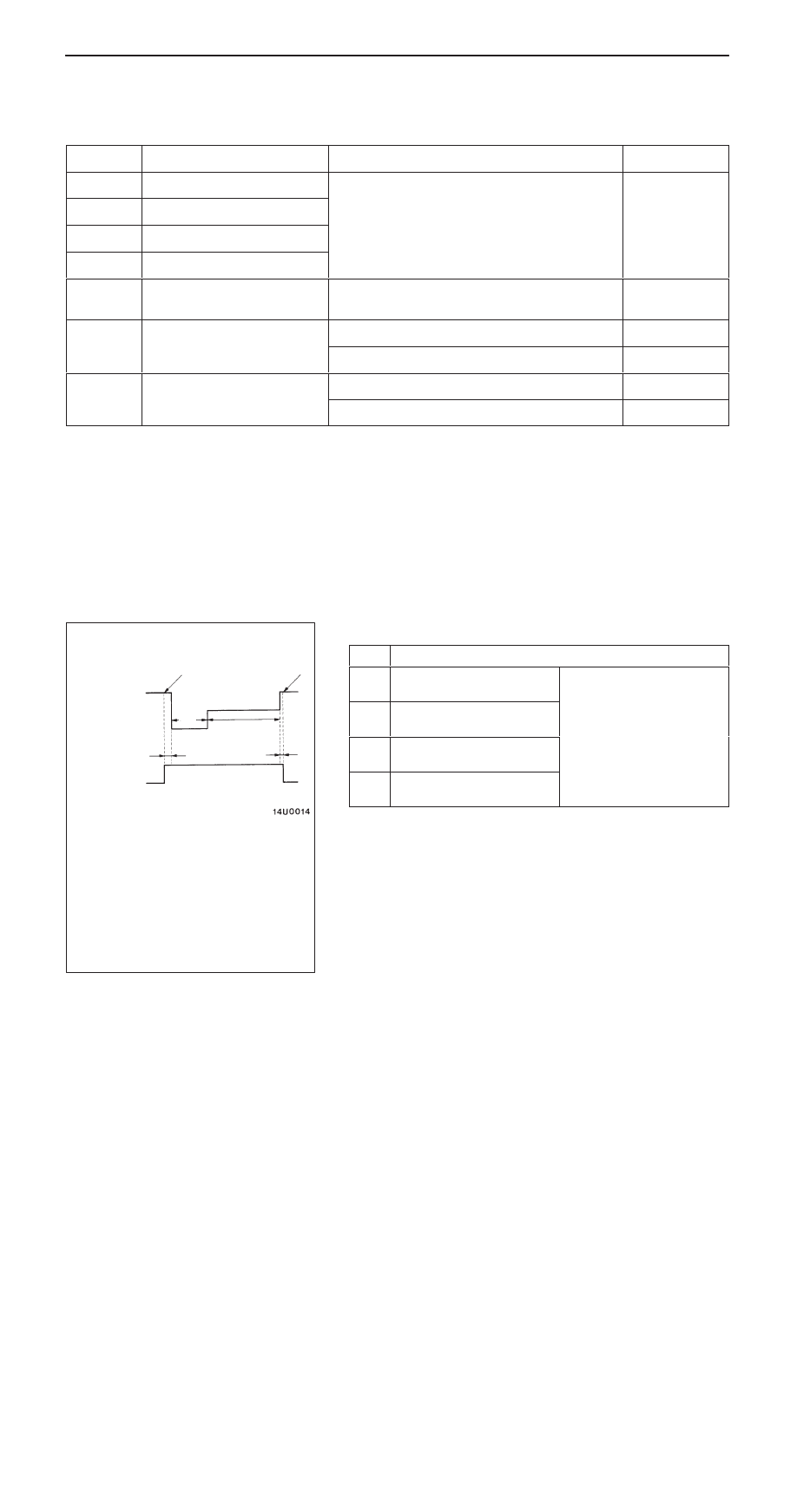

2s

1s

Activation pattern

Solenoid

valve

Pump

motor

ON

OFF

Start of

forced

action

End of forced

action

A

B

C

0.05 s

0.01 s

NOTE

A: Hydraulic pressure increase

B: Hydraulic pressure holds

C: Hydraulic pressure decrease