Mitsubishi Pajero Pinin. Manual - part 248

ABS <4WD> –

Troubleshooting

35B-15

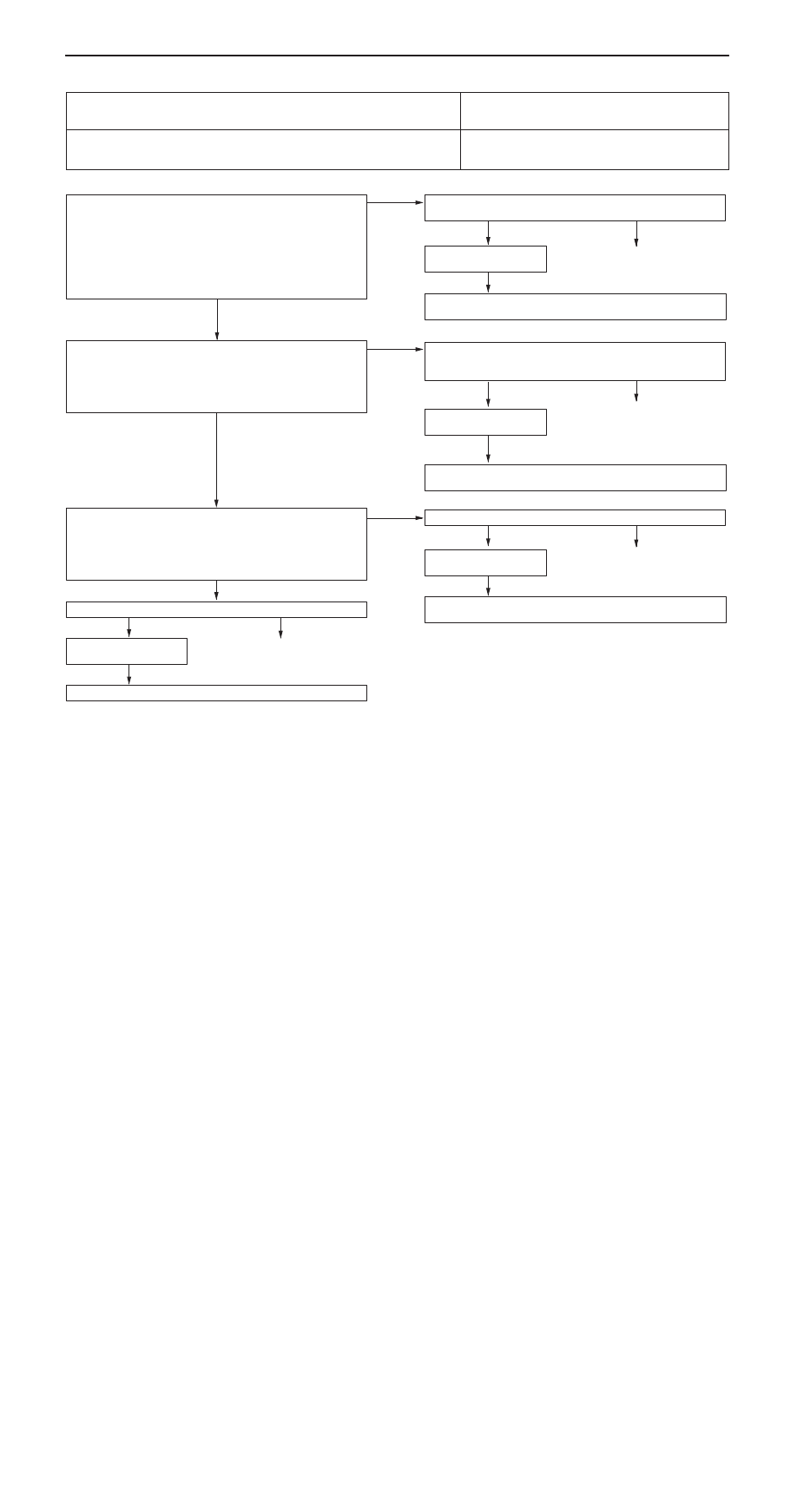

Inspection Procedure 2

Communication between MUT-

II

and the ABS-ECU is not

possible.

Probable cause

The cause may be an open circuit in the ABS-ECU power supply circuit or an open

circuit in the diagnosis output circuit.

D

Blown fuse

D

Malfunction of wiring harness or connector

D

Malfunction of hydraulic unit and ABS-ECU

NG

NG

NG

Repair

NG

Check the harness wire, and repair if necessary.

D

Between ABS-ECU and diagnosis connector

OK

NG

Repair

NG

Check the harness wire, and repair if necessary.

D

Between ignition switch and ABS-ECU

OK

NG

Repair

NG

Check the harness wire, and repair if necessary.

D

Between ABS-ECU and earth

NG

Repair

NG

Replace the hydraulic unit and ABS-ECU.

OK

Check the trouble symp-

tom.

OK

Check the trouble symp-

tom.

OK

Check the following connector: A-58

Measure at the ABS-ECU connector A-58.

D

Disconnect the connector, and measure at the harness side

connector.

D

Continuity between 21 and body earth, and between 23 and

body earth

OK: Continuity

Check the following connector: A-58

OK

Check the trouble symp-

tom.

Measure at the ABS-ECU connector A-58.

D

Disconnect the connector, and measure at the harness side

connector.

D

Ignition switch: ON

D

Voltage between 10 and body earth

OK: System voltage

Check the following connectors: A-58, C-40 <R.H. drive

vehicles>, C-02 <R.H. drive vehicles>, C-78 <L.H. drive vehicles>,

C-76 <R.H. drive vehicles>, C-74

OK

Check the trouble symp-

tom.

Measure at the diagnosis connector C-35 and the ABS-ECU con-

nector A-58.

D

Disconnect the connectors, and measure at the harness side

connectors.

D

Continuity between the following terminals

ABS-ECU side – Diagnosis connector side

19 – 1

9 – 7

OK: Continuity

NG

Check the following connectors: A-58, C-28 <L.H. drive

vehicles>, C-40 <R.H. drive vehicles>, C-70, C-35