Mitsubishi Pajero Pinin. Manual - part 237

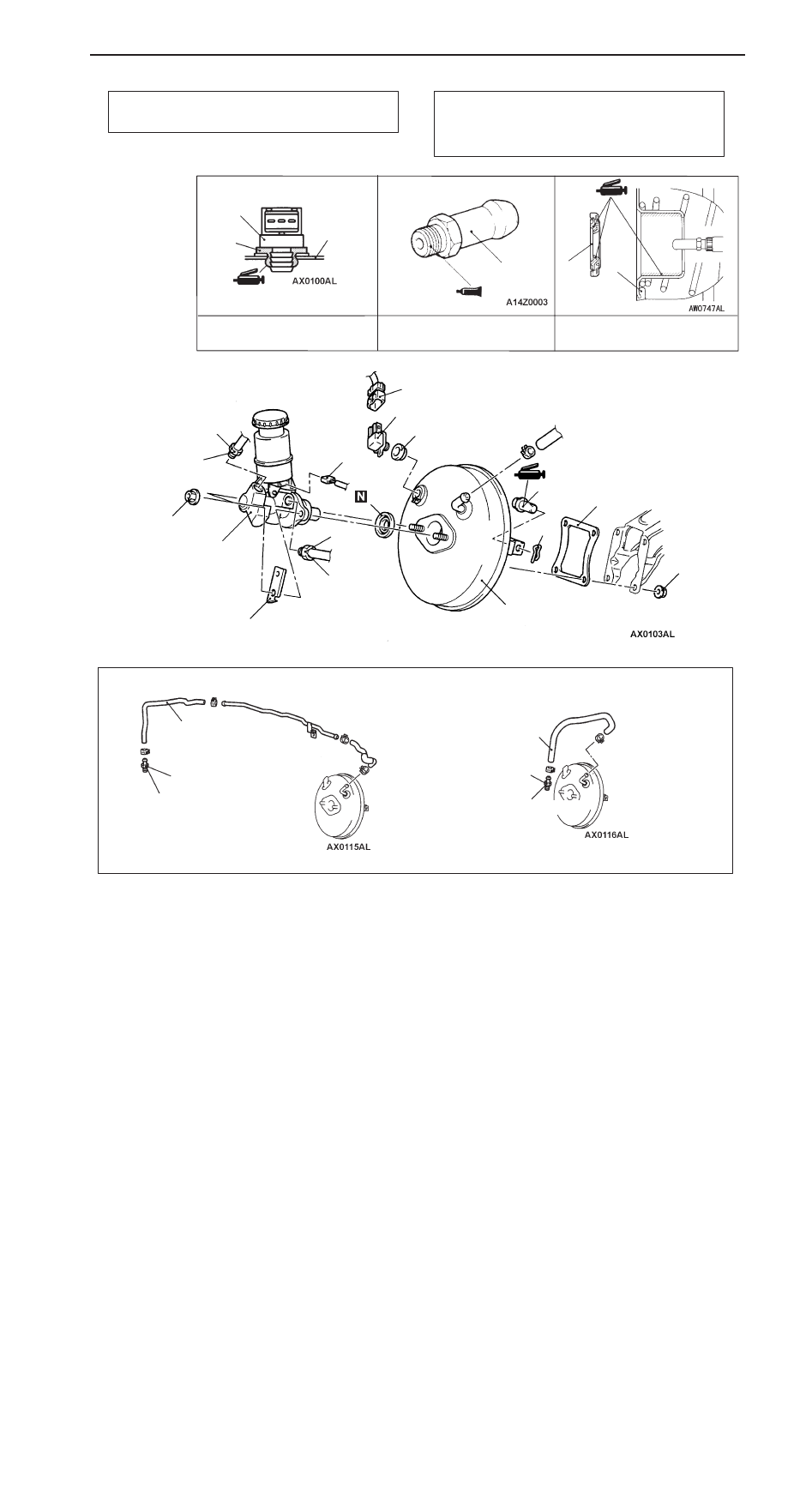

BASIC BRAKE SYSTEM –

Master Cylinder and Brake Booster

35A-16

<L.H. drive vehicles without ABS and R.H. drive vehicles>

Pre-removal Operation

Brake Fluid Draining

Post-installation Operation

D

Brake Fluid Supplying and Air Bleeding

(Refer to P.35A-10.)

D

Brake Pedal Adjustment (Refer to P.35A-6.)

Specified Sealant: 3M ATD

Part No.8661 or equivalent

Grease: Silicone grease

11

4

7

8

14

9

10

1

2

12

12 Nm

15 Nm

14 Nm

15 Nm

1

3

11

6

14

14.7 – 17.7 Nm

12

10

5

13

<L.H. drive vehicles>

14

<R.H. drive vehicles>

14.7 – 17.7 Nm

6

Grease: Silicone grease

12

4