Mitsubishi Pajero Pinin. Manual - part 125

MPI <4G9> –

Troubleshooting

13C-86

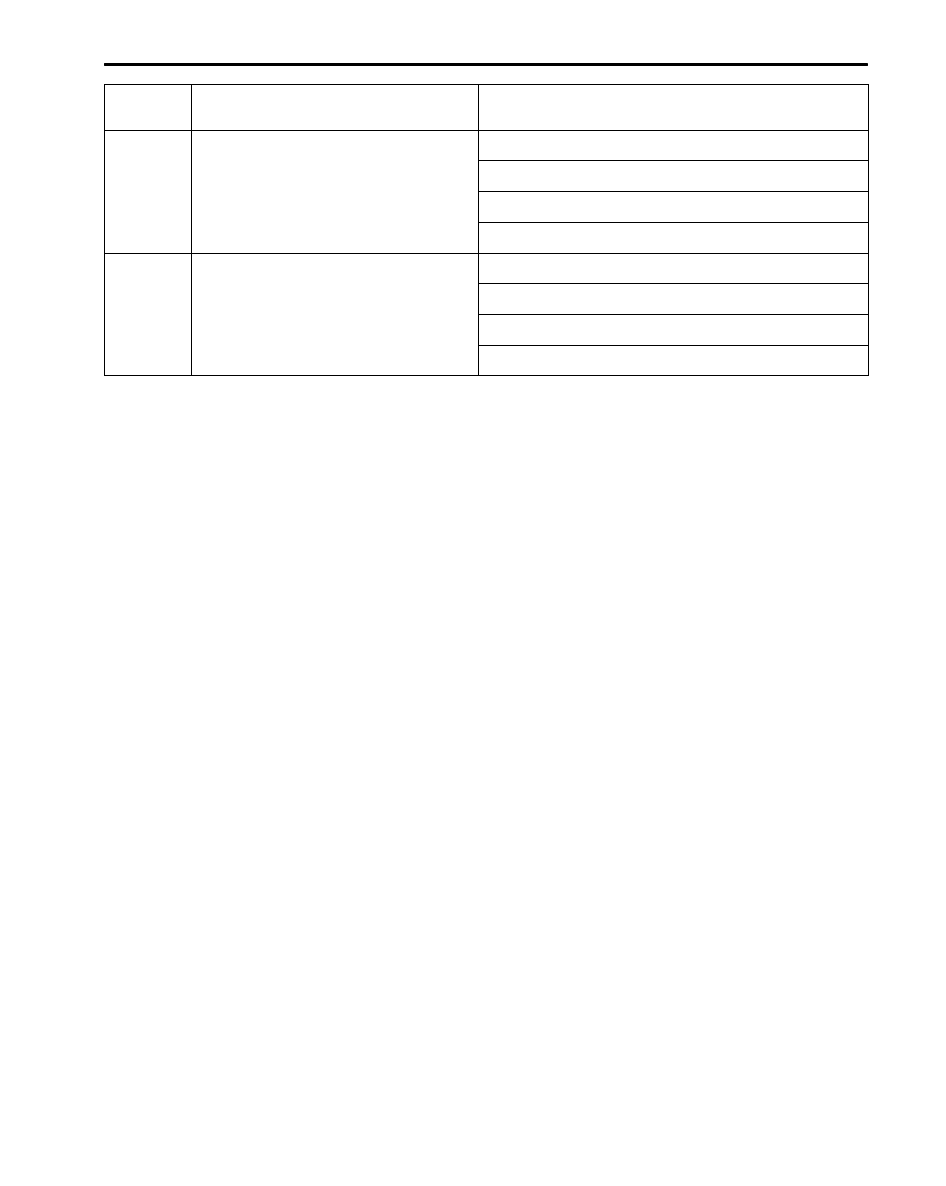

Terminal

No.

Normal condition (Check condition)

Inspection item

72 – 92

Intake air temperature sensor

5.3 – 6.7 k

Ω

(When intake air temperature is 0

_

C)

2.3 – 3.0 k

Ω

(When intake air temperature is 20

_

C)

1.0 – 1.5 k

Ω

(When intake air temperature is 40

_

C)

0.30 – 0.42 k

Ω

(When intake air temperature is 80

_

C)

83 – 92

Engine coolant temperature sensor

5.1 – 6.5 k

Ω

(When coolant temperature is 0

_

C)

2.1 – 2.7 k

Ω

(When coolant temperature is 20

_

C)

0.9 – 1.3 k

Ω

(When coolant temperature is 40

_

C)

0.26 – 0.36 k

Ω

(When coolant temperature is 80

_

C)