Mitsubishi Pajero Pinin. Manual - part 123

MPI <4G9> –

Troubleshooting

13C-78

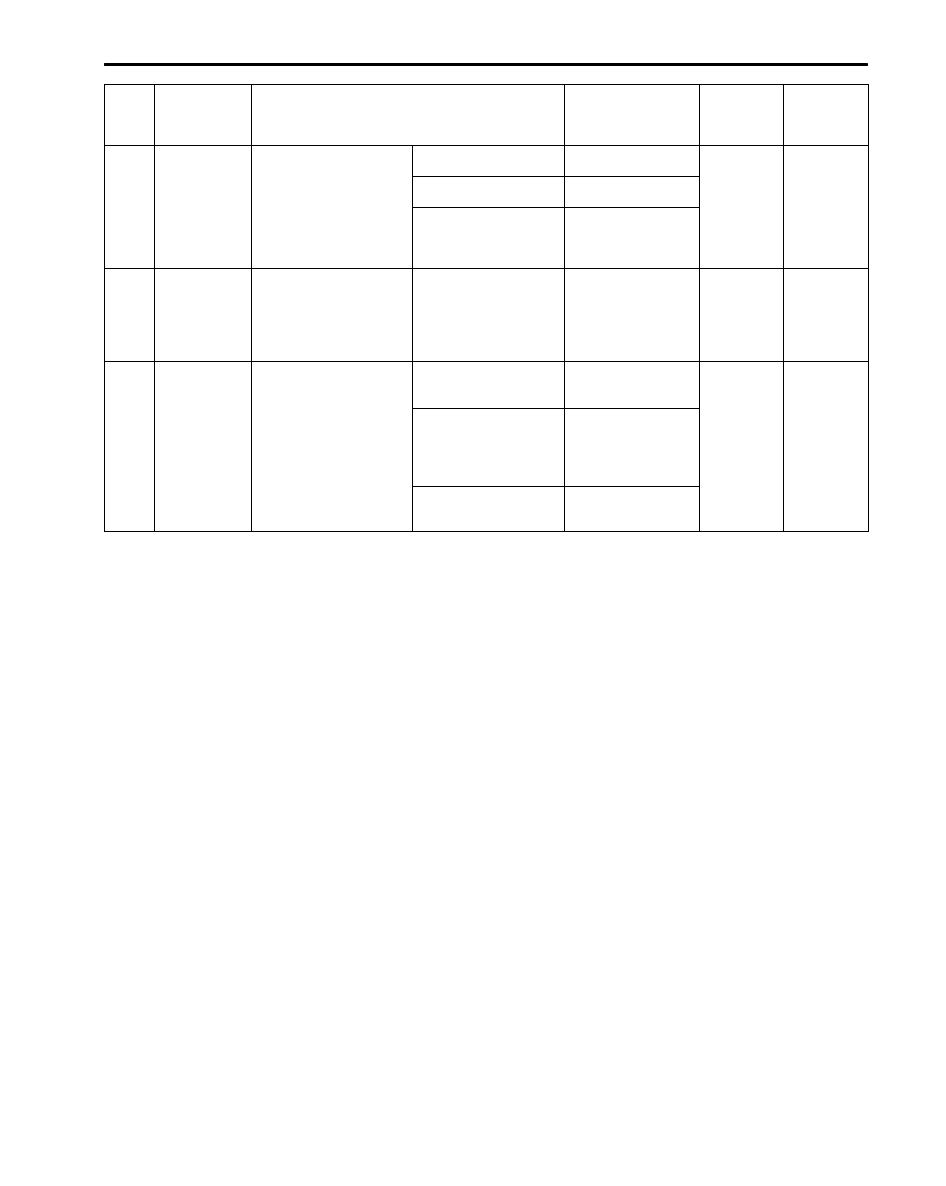

Item

No.

Reference

page

Inspection

procedure

No.

Normal condition

Inspection contents

Inspection

item

A1

L

Oxygen

sensor

Engine: After warm-up

Idling

0.2 V or less

Code No.

P0130

13C-25

L

sensor

(sensor 1)

Sudden racing

0.6 – 1.0 V

P0130

2,500 r/min

0.4 V or less and

0.6 – 1.0 V alter-

nates

A2

L

Oxygen

sensor

(sensor 2)

D

Transmission:

2nd gear <M/T>,

L range <A/T>

D

Drive with throttle

widely open

3,500 r/min

0.6 – 1.0 V

Code No.

P0136

13C-27

8A

L

Throttle

position

sensor

D

Engine coolant

temperature:

80

95

_

C

Release the acceler-

ator pedal.

6 – 20 %

Code No.

P0120

13C-22

sensor

(Throttle

valve open-

ing angle)

80 – 95

_

C

D

Ignition switch:

ON

(Engine: Stopped)

Depress the acceler-

ator pedal gradually

Increase in re-

sponse to pedal

depression

stroke.

Depress the acceler-

ator pedal fully.

80 – 100 %