Mitsubishi Pajero Pinin. Manual - part 52

GDI –

Troubleshooting

13A-74

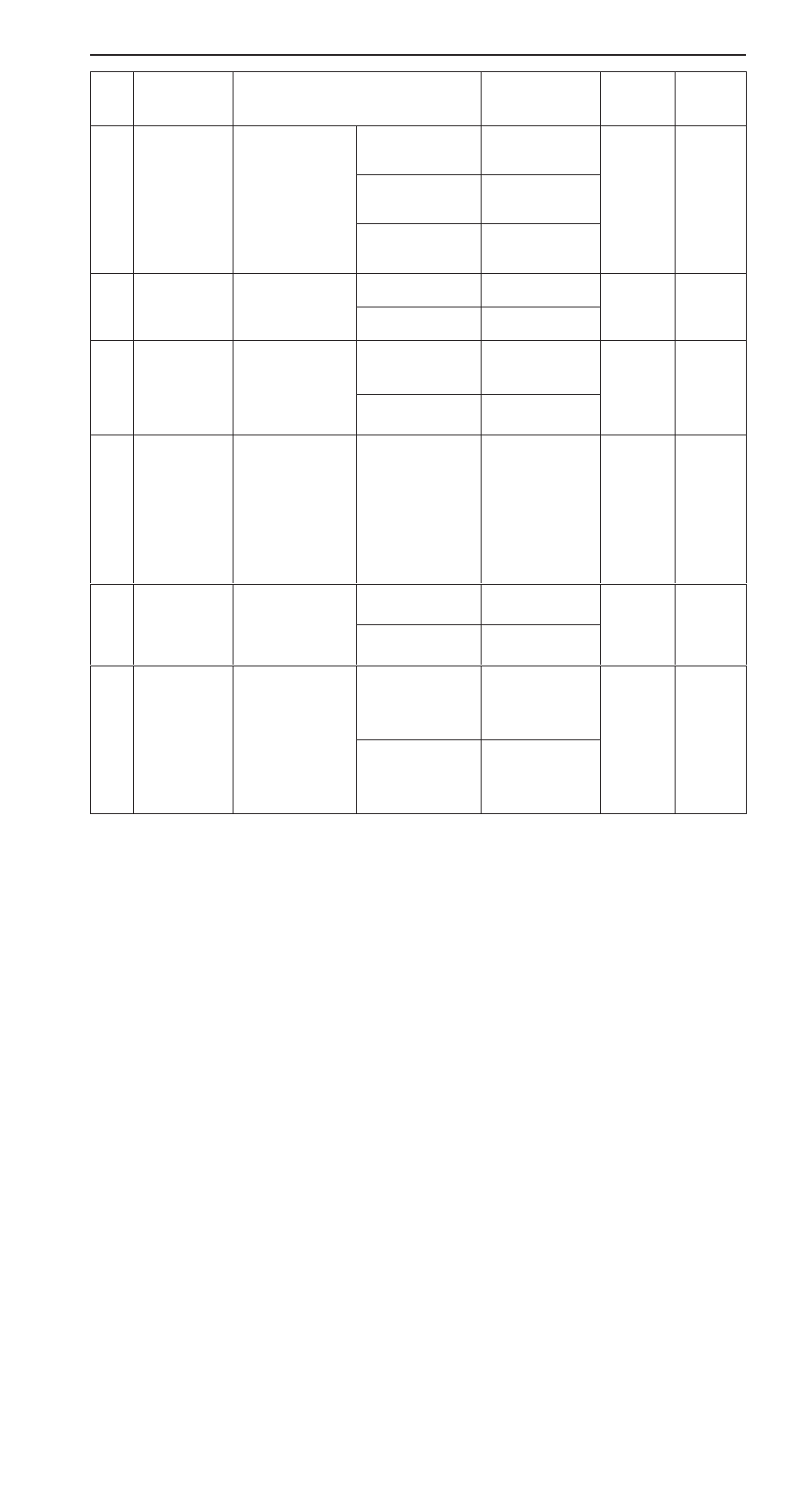

Item

No.

Refer-

ence

page

Inspection

procedure

No.

Normal condition

Requirements

Check items

41

Injector drive

time *

2

D

Engine coolant

temperature: 80

– 95

_

C

L

l

t i

Idling

0.5 – 0.7 ms*

1

Code

No.41

13A-25

D

Lamps, electric

cooling fan and

all accessories:

OFF

2,500 r/min

0.4 – 0.8 ms

OFF

D

Transmission:

Neutral (A/T: P

range)

Sudden racing

Increases

44

Ignition

advance

D

Engine: After

warm-up

Idling

12 – 20

_

BTDC *

2

Code

No.44

13A-27

advance

warm u

D

Set a timing

light.

2,500 r/min

20 – 40

_

BTDC

No.44

49

A/C relay

Engine: After warm-

up, idling

A/C switch: OFF

OFF (compressor

clutch is not oper-

ating)

Procedure

No.32

13A-69

A/C switch: ON

ON (compressor

clutch is operating)

66

Brake vacuum

sensor

D

Engine coolant

temperature: 80

– 95

_

C

D

Lamps, electric

cooling fan and

all accessories:

OFF

D

Transmission:

Neutral

(A/T: P range)

Stop the engine

from idling speed,

and then depress

the brake pedal

several times with

the ignition switch

on.

Displayed pres-

sure increases.

Code

No.66

13A-32

67

Stop lamp

switch

Ignition switch: ON

Brake pedal:

Depressed

OFF

Procedure

No.33

13A-70

Brake pedal:

Released

ON

68

EGR valve

D

Engine coolant

temperature: 80

– 95

_

C

D

Lamps, electric

cooling fan and

Idling

0 – 15 STEP

Procedure

No.29

13A-67

cooling fan and

all accessories:

OFF

D

Transmission:

Neutral

(A/T: P range)

2,500 r/min

0 – 10 STEP