Mitsubishi Pajero Pinin. Manual - part 51

GDI –

Troubleshooting

13A-70

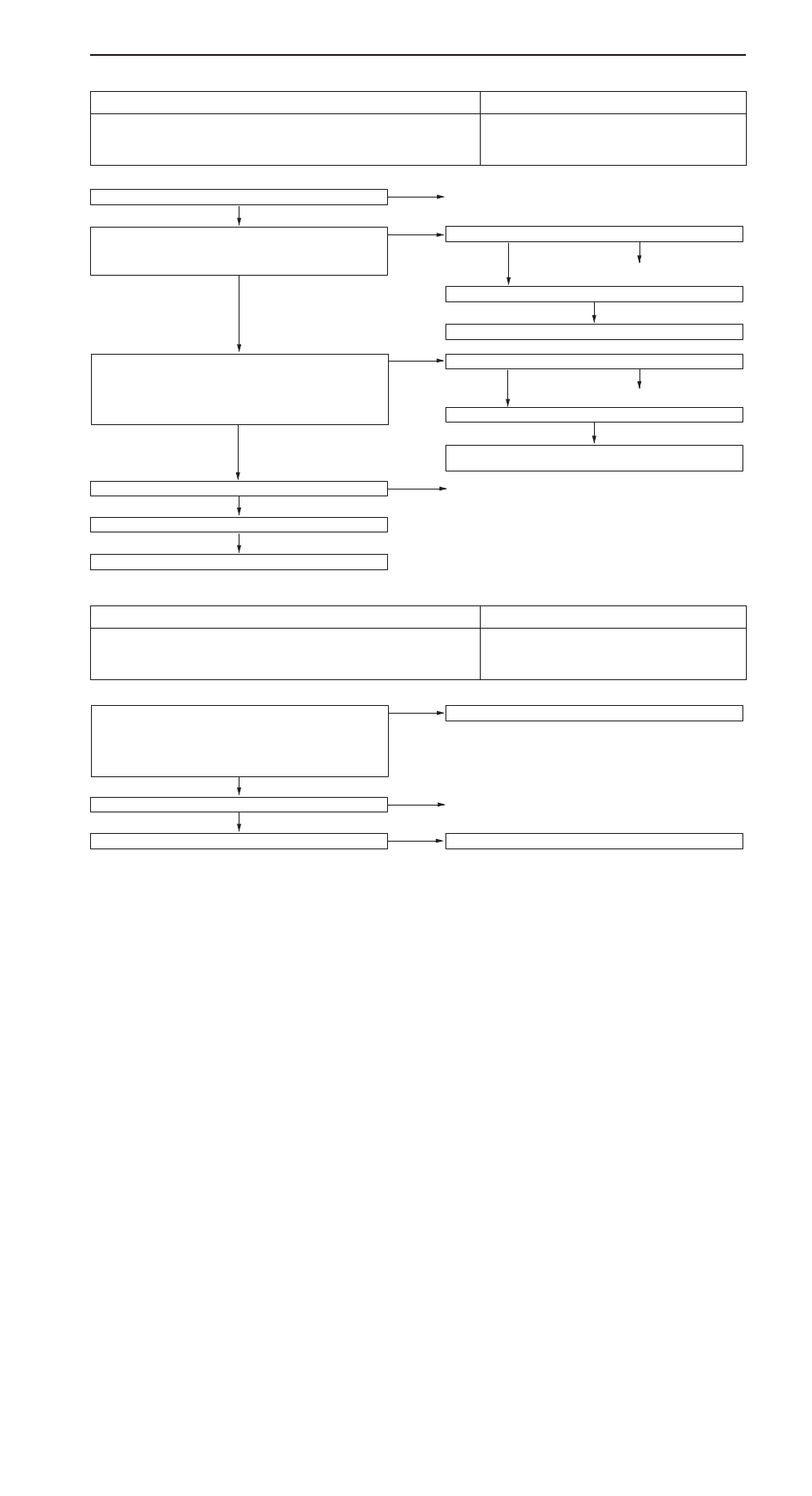

INSPECTION PROCEDURE 33

Stop lamp switch system

Probable cause

The engine-ECU determines whether the brake pedal is depressed or not, by means

of the stop lamp switch input signal.

D

Malfunction of the stop lamp switch

D

Open circuit or short-circuited harness wire in the

stop lamp circuit, or poor connector contact

D

Malfunction of the engine-ECU

NG

NG

NG

Repair

Check the stop lamp switch. (Refer to GROUP 35 – Brake Pedal.)

NG

Replace

OK

Measure at stop lamp switch connector C-04.

D

Disconnect the connector, and measure at the harness side.

D

Voltage between terminal 2 and earth

OK: System voltage

NG

Check the following connector: C-29

OK

Check trouble symptom.

Check the harness wire between the battery and stop lamp switch.

NG

Repair

OK

Measure at engine-ECU connector C-18.

D

Disconnect the connector, and measure at the harness side.

D

Voltage between terminal 63 and earth

(Ignition switch: ON)

OK: 0 – 3 V (when the brake pedal is not depressed)

System voltage (when the brake pedal is depressed)

NG

Check the following connectors: C-02, C-04, C-28

OK

Check trouble symptom.

Check the harness wire between the engine-ECU and stop lamp,

and repair if necessary.

OK

Check the following connector: C-18

NG

Repair

OK

Check trouble symptom.

NG

Replace the engine-ECU.

INSPECTION PROCEDURE 34

Small lamp switch

Probable cause

The engine-ECU determines whether the small lamp switch is on or off.

According to that information, the engine-ECU controls

alternator output current when the vehicle is started.

D

Improper connector contact, open circuit or

short-circuited harness wire in the taillamp relay

circuit

D

Malfunction of the engine-ECU

NG

Replace the engine-ECU.

OK

Check the trouble symptoms.

OK

Check the following connector: C-19

NG

Repair

Measure at the engine-ECU connector C-19.

D

Disconnect the connector, and measure at the harness

side.

D

Voltage between 88 and earth

(Lighting switch: ON)

OK: System voltage

NG

Check the taillamp relay circuit. (Refer to ELECTRICAL WIRING.)