Mitsubishi Pajero Pinin. Manual - part 46

GDI –

Troubleshooting

13A-50

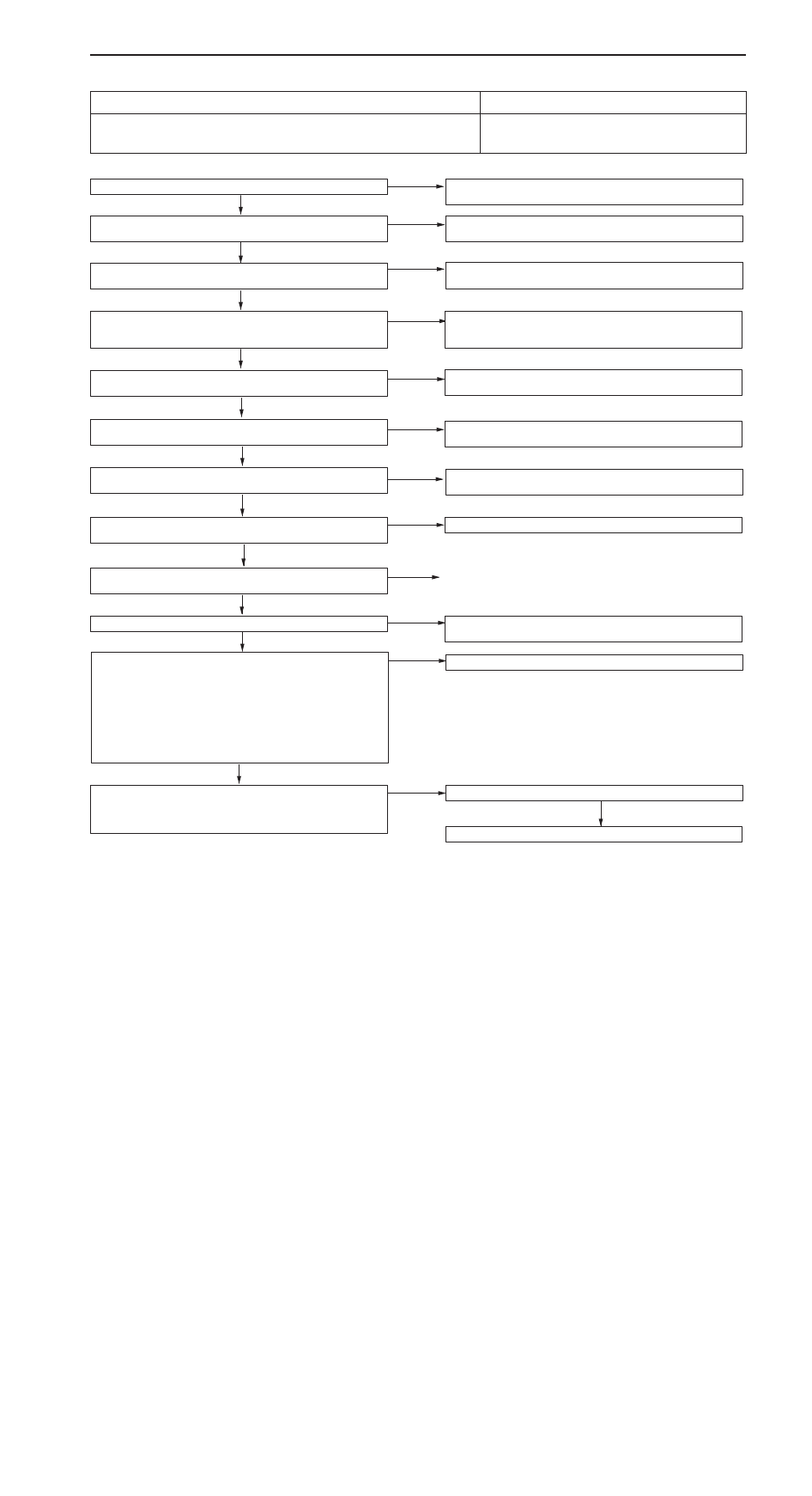

INSPECTION PROCEDURE 9

When the engine is cold, it stalls at idling. (Die out)

Probable cause

The cause is probably an incorrect air/fuel ratio or poor intake air amount when

the engine is cold.

D

Malfunction of the electronic-control throttle valve

system

D

Malfunction of the throttle body

Have the battery terminals been disconnected recently?

Yes

Warm up the engine, and then let it run at idle for approx. ten

minutes.

No

MUT-

II

Self-Diag code

Is a diagnosis code displayed?

Yes

Refer to P.13A-14, INSPECTION CHART FOR DIAGNOSIS

CODES.

No

Is the engine idling correct after the engine has been warmed

up?

Yes

Refer to “Unstable idling (rough idle, hunting).” (Refer to P.13A-47,

INSPECTION PROCEDURE 7.)

No

MUT-

II

Data list

22 Crank angle sensor (Refer to P.13A-72.)

Check idling speed when the engine is cold.

NG

Check the throttle valve position feedback system. (Refer to

P.13A-37, INSPECTION PROCEDURE FOR DIAGNOSIS CODE

92.)

OK

MUT-

II

Data list

26 Accelerator pedal position switch (Refer to P.13A-73.)

NG

Check the accelerator position switch. (Refer to P.13A-65, IN-

SPECTION PROCEDURE 27.)

OK

MUT-

II

Data list

21 Engine coolant temperature sensor (Refer to P.13A-72.)

NG

Check the engine coolant temperature sensor. (Refer to P.13A-19,

INSPECTION PROCEDURE FOR DIAGNOSIS CODE 21.)

OK

MUT-

II

Data list

68 EGR valve (Refer to P.13A-74.)

NG

Check the EGR valve system. (Refer to P.13A-67, INSPECTION

PROCEDURE 29.)

OK

Does the engine stall immediately after the accelerator pedal is

released?

Yes

Clean around the throttle valve. (Refer to P.13A-92.)

No

Measure fuel high pressure between the fuel pump (high pressure)

and injector. (Refer to P.13A-97.)

NG

Repair

OK

Check ignition timing. (Refer to GROUP 11A – Engine Adjustment.)

NG

Check that the crank angle sensor and timing belt cover are proper-

ly installed.

OK

Check ignition coil spark for each cylinder.

(1) Remove the ignition coil.

(2) Install a new spark plug to the removed ignition coil.

(3) Disconnect the injector intermediate connector.

Caution

Never touch the connector terminal as approx. 100 V is

applied to the injector, or you are seriously injured.

(4) Earth the spark plug electrode securely.

(5) Check that the spark plug ignites when the engine is cranked.

NG

Replace the ignition coil.

OK

Check all the following items:

D

Spark plugs

D

Compression pressure

D

Engine oil viscosity

NG

Check trouble symptom.

OK

Replace the injector.