Mitsubishi Pajero Pinin. Manual - part 44

GDI –

Troubleshooting

13A-42

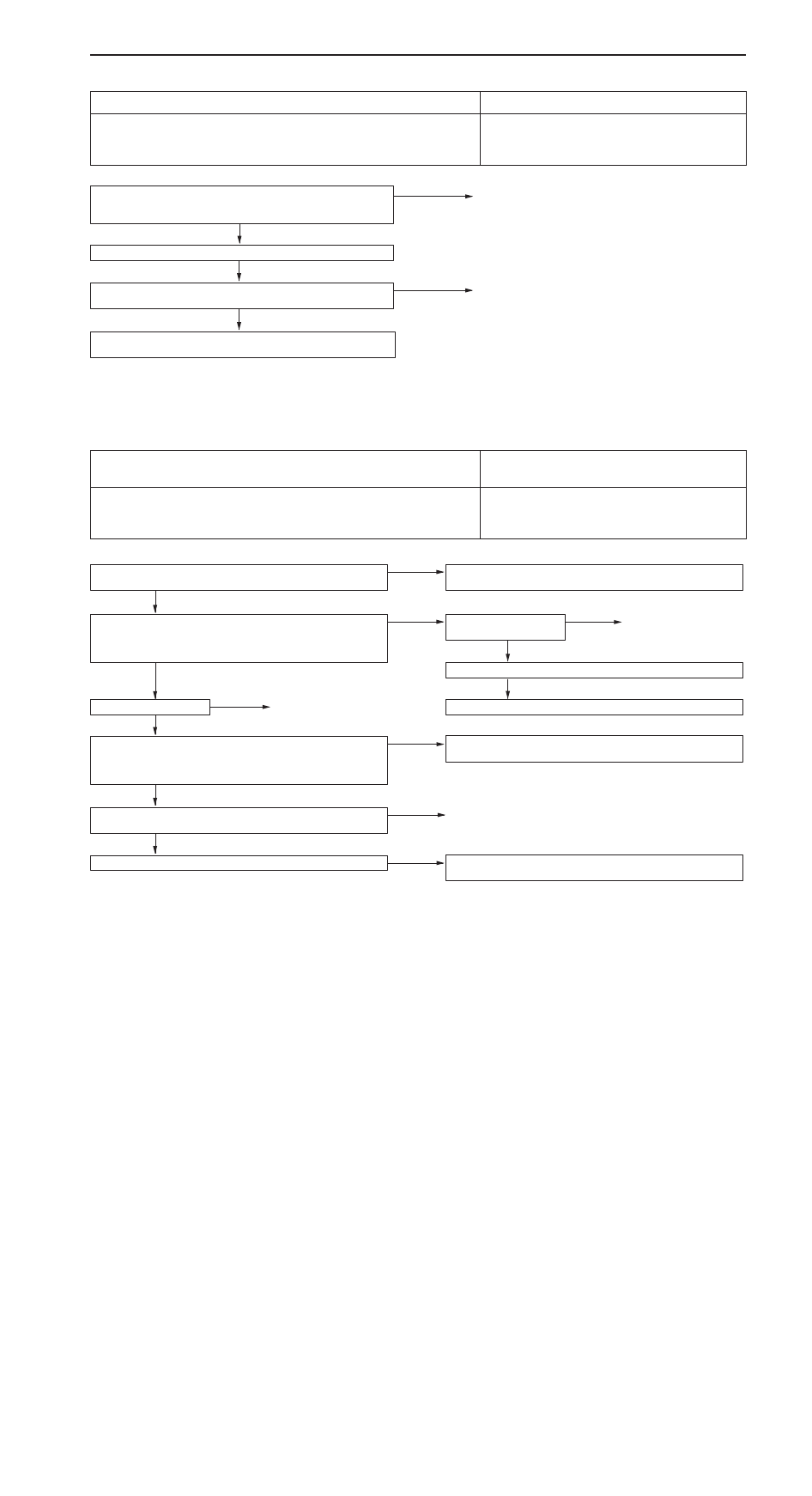

INSPECTION PROCEDURE 2

MUT-

II

communication with engine-ECU is impossible.

Probable cause

This may be caused by malfunction of engine-ECU power supply circuit and earth

circuit.

D

Malfunction of engine-ECU power supply circuit

D

Malfunction of engine-ECU

D

Open circuit between the engine-ECU and diagnosis

connector

NG

Check the harness wire between engine-ECU and diagnosis con-

nector.

NG

Repair

OK

Check trouble symptom.

Check the following connectors:

C-53 <Vehicles with multi center display>, C-19, C-28, C-35,

C-70

NG

Repair

OK

Check the engine-ECU power supply and earth circuit system. (Refer

to P.13A-62, INSPECTION PROCEDURE 23.)

NOTE

On vehicles with multi center display, if a malfunction cannot be resolved after the procedure above, check

the multi center display and replace if necessary. (Refer to GROUP 54 – Multi center display.)

INSPECTION PROCEDURE 3

The engine warning lamp does not illuminate right after

the ignition switch is turned to the ON position.

Probable cause

Because there is a burnt-out bulb, the engine-ECU causes the engine warning lamp

to illuminate for five seconds immediately after the ignition switch is turned to ON.

If the engine warning lamp does not illuminate immediately after the ignition switch

is turned to ON, one of the malfunctions listed at right has probably occurred.

D

Burnt-out bulb

D

Defective warning lamp circuit

D

Malfunction of the engine-ECU

MUT-

II

Data list

16 Engine-ECU power supply voltage (Refer to P.13A-72.)

NG

Check the engine-ECU power supply and earth circuit system.

(Refer to P.13A-62, INSPECTION PROCEDURE 23.)

OK

Measure at the engine-ECU connector C-17.

D

Disconnect the connector, and measure at the harness side.

D

Earth the terminal No. 31.

OK: The engine warning lamp illuminates.

OK

Check the following

connector: C-17

NG

Repair

OK

Check trouble symptom.

NG

Replace the engine-ECU.

NG

Check a burnt-out bulb.

NG

Replace

OK

Measure at the combination meter connector C-06.

D

Disconnect the connector, and measure at the harness side.

D

Voltage between 1 and earth (Ignition switch: ON)

OK: System voltage

NG

Check the engine warning lamp power supply circuit, and repair

if necessary.

OK

Check the following connectors:

C-06, C-07, C-17, C-28

NG

Repair

OK

Check trouble symptom.

NG

Check the harness wire between combination meter and engine-

ECU, and repair if necessary.