Mitsubishi Pajero Pinin. Manual - part 24

ENGINE <4G9-MPI> –

On-vehicle Service

11B-7

ALTERNATOR DRIVE BELT TENSION ADJUSTMENT

1.

Loosen the nut of the alternator pivot bolt.

2.

Loosen the lock bolt.

3.

Use the adjusting bolt to adjust the belt tension and belt

deflection to the standard values.

Standard value:

Items

When adjusted

When replaced

Vibration frequency Hz

155 – 175

203 – 234

Tension N

343 – 441

588 – 784

Deflection

(Reference) mm

10.5 – 12.0

6.7 – 8.5

4.

Tighten the nut of the alternator pivot bolt.

Tightening torque: 44

±

10 N·m

5.

Tighten the lock bolt.

Tightening torque: 23

±

2 N·m

6.

Tighten the adjusting bolt.

Tightening torque: 5.0

±

1.0 N·m

POWER STEERING OIL PUMP DRIVE BELT <Vehicles

without A/C>, POWER STEERING OIL PUMP AND A/C

COMPRESSOR DRIVE BELT <Vehicles with A/C> TENSION

CHECK AND ADJUSTMENT

1.

Check if the belt tension is within the standard value using

one of the methods below.

Standard value:

Items

When

checked

When

adjusted

When

replaced

Vibration

frequency

Hz

114 – 139

121 – 133

145 – 166

Tension N

392 – 588

441 – 539

637 – 833

Deflection

(Reference)

mm

10.0 – 12.0

10.0 – 11.0

7.0 – 9.0

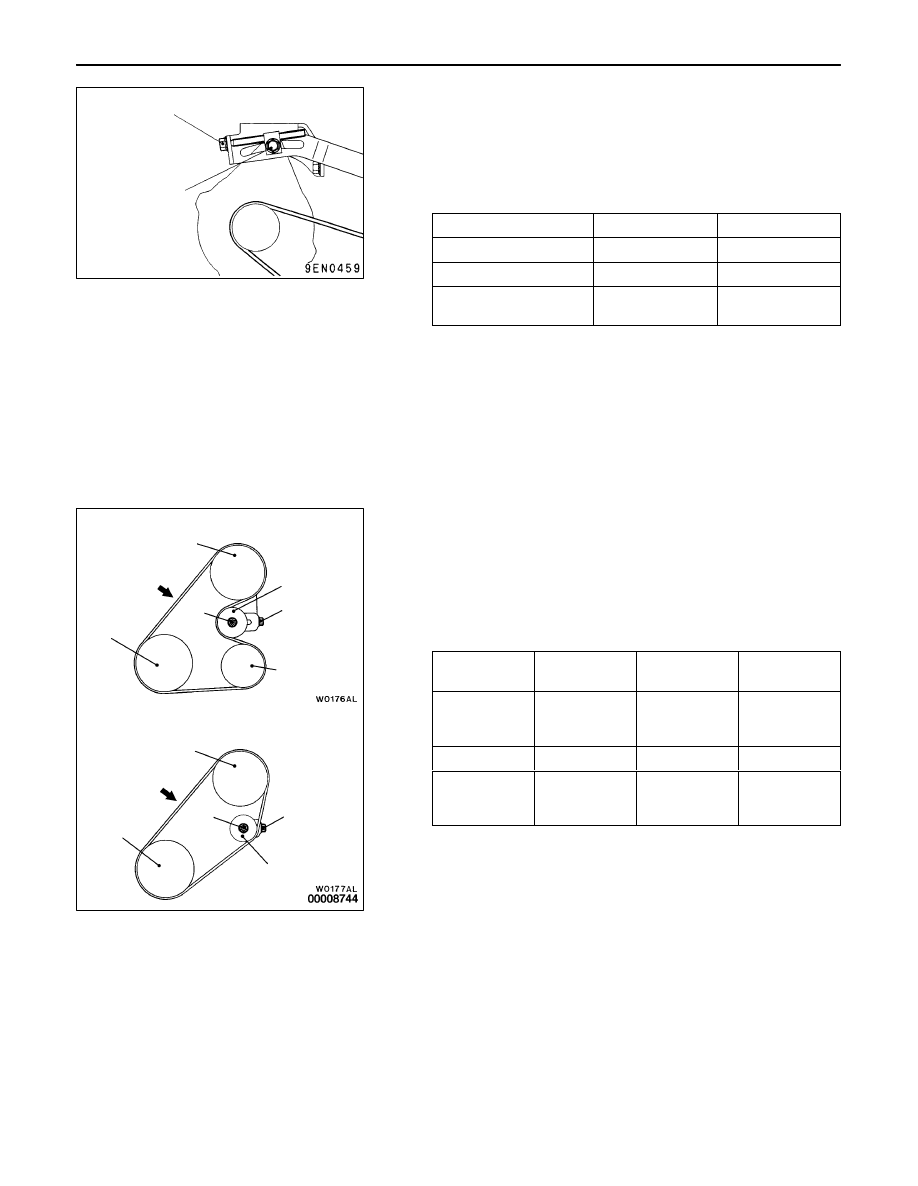

<When measuring the vibration frequency>

With your finger tip lightly tap the centre of the belt between

the pulleys in the location shown by the arrow in the

illustration and then measure the belt vibration frequency.

NOTE

Refer to P.11B-6 for information regarding the vibration

frequency measurement method using MUT-

II

.

<When measuring the tension>

Use a belt tension gauge to measure the belt tension.

Adjusting bolt

Lock bolt

<Vehicles without A/C>

<Vehicles with A/C>

Oil pump pulley

Crankshaft

pulley

Tension

pulley

A

B

Oil pump pulley

Crankshaft

pulley

Tension

pulley

A

B

A/C

compressor

pulley