Mitsubishi Space Star. Manual - part 120

AUTOMATIC TRANSMISSION –

On-vehicle Service

23-47

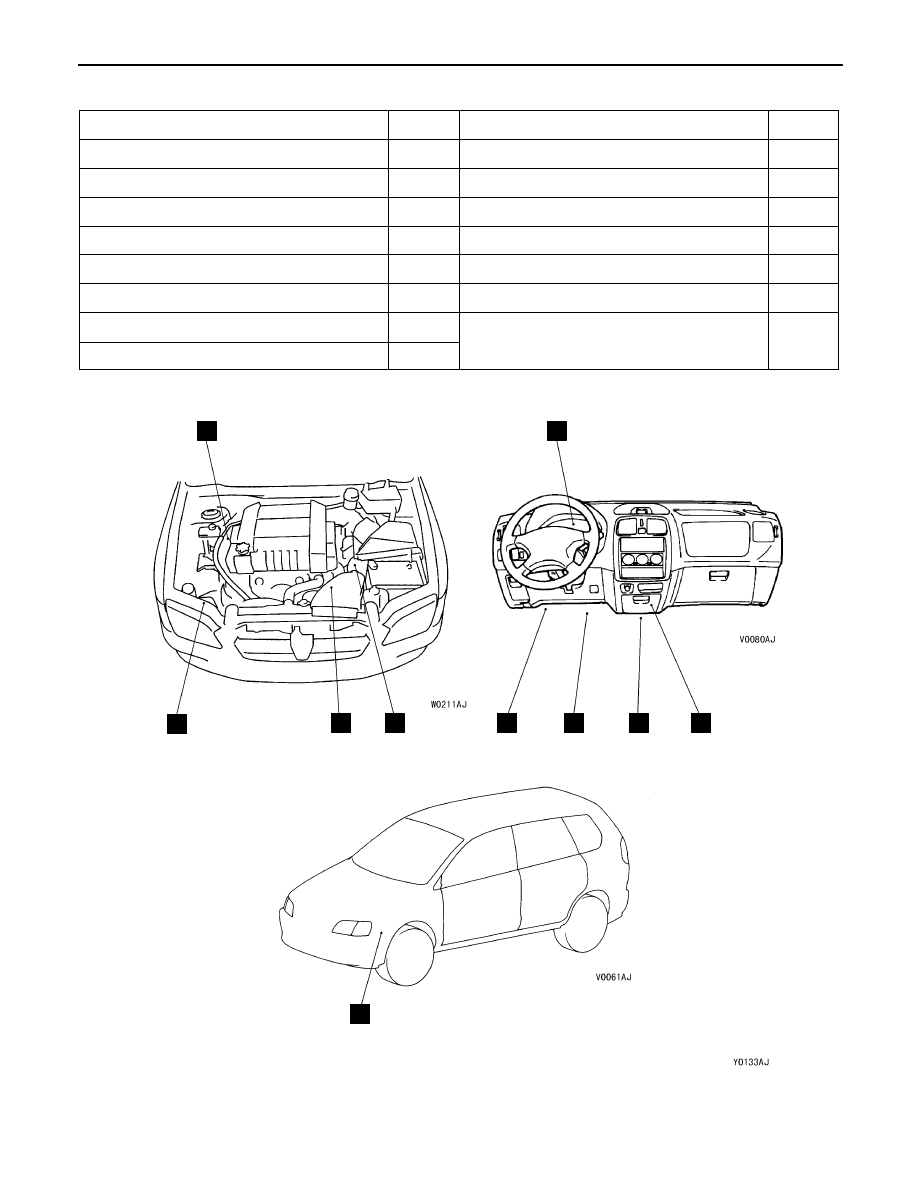

A/T CONTROL COMPONENT LOCATION

Name

Symbol

Name

Symbol

Accelerator position sensor

J

Input shaft speed sensor

D

A/T control relay

I

A/T fluid temperature sensor

D

A/T control solenoid valve assembly

D

Output shaft speed sensor

D

Crank angle sensor

A

Shift indicator lamp

E

Diagnosis connector

H

Stop lamp switch

F

Dual pressure switch

B

Vehicle speed sensor

D

Engine-A/T-ECU

I

Wide open throttle switch

G

Inhibitor switch

C

A

B

C

D

E

F

G

H

I

J