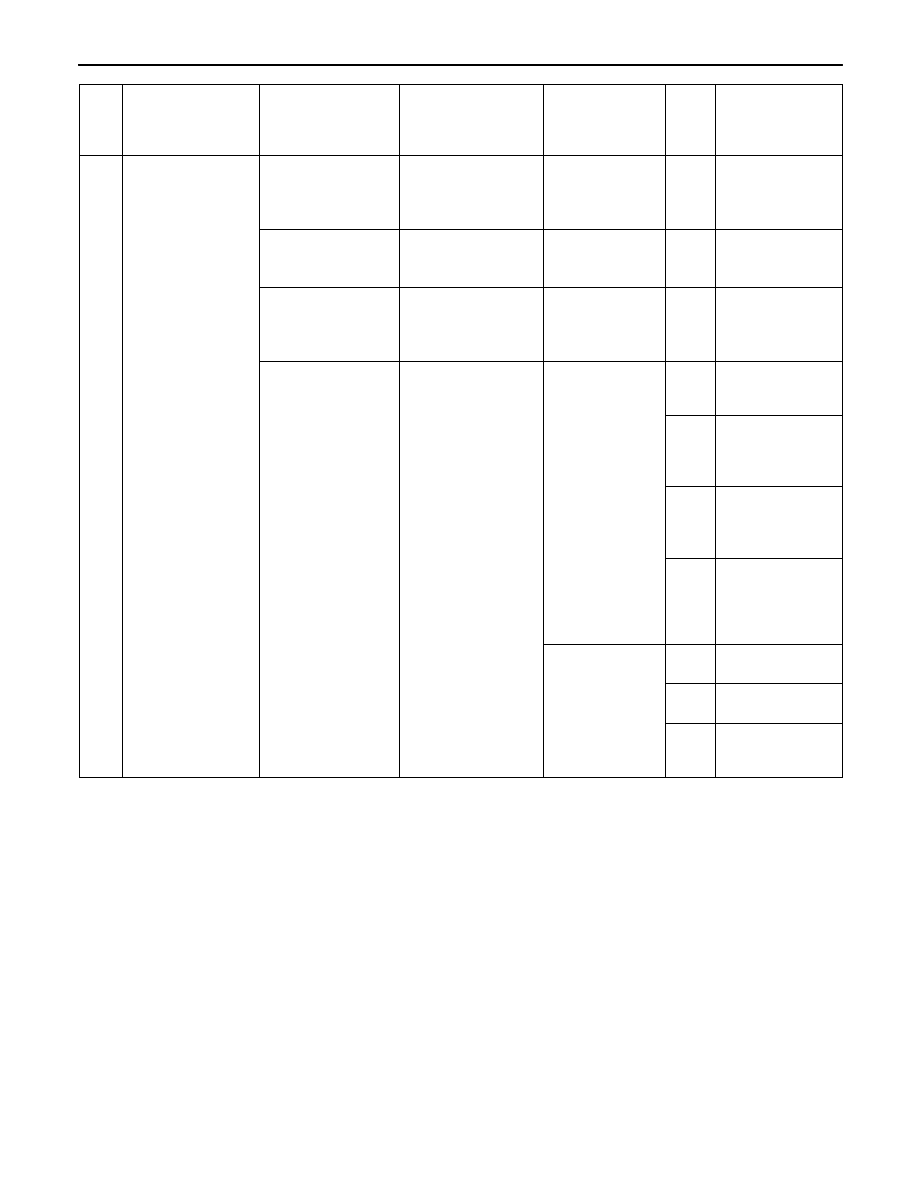

Mitsubishi Space Star. Manual - part 110

AUTOMATIC TRANSMISSION –

Troubleshooting <A/T>

23-7

No.

Inspection

procedure page

if there is an

abnormality

Diag-

nosis

code

No.

Check item

Judgement value

Test and operation

State prior to test

and operation

5

Engine: Idling

Selector lever

position: N

Brake pedal

(Retest)

(1) Depressed

(2) Released

Data list No. 26

(1) ON

(2) OFF

Stop lamp

switch

26

Stop lamp switch

system (23-15)

A/C switch

(1) ON

(2) OFF

Data list No. 65

(1) ON

(2) OFF

Dual pressure

switch

–

Dual pressure

switch system

(23-30)

Accelerator pedal

(1) Released

(2) Half depressed

Data list No. 21

(1) 550 – 850 r/min

Gradually rises

from (1)

Crank angle

sensor

21

Crank angle

sensor system

(23-12)

Selector lever

position

(1) N

→

D

Should be no

abnormal shifting

shocks

Malfunction

when starting

–

Engine stalling

during shifting

(23-23)

(1) N

→

D

(2) N

→

R

Time lag should be

within 2 seconds

–

Shocks when

changing from N

to D and large

time lag (23-23)

–

Shocks when

changing from N

to R and large

time lag (23-24)

–

Shocks when

changing from N

to D,N to R and

large time lag

(23-25)

Driving

impossible

–

Does not move

forward (23-21)

–

Does not

reverse (23-22)

–

Does not move

(forward or

reverse) (23-22)