Mitsubishi Space Star. Manual - part 73

MPI –

On-vehicle Service

13B-79

NOTE

Unless the ISC servo is released, the Actuator test mode

will continue 27 minutes.

8.

Switch OFF the ignition switch.

9.

Disconnect the MUT-

II.

10. Start the engine again and let it run at idle speed for

about 10 minutes; check that the idling condition is normal.

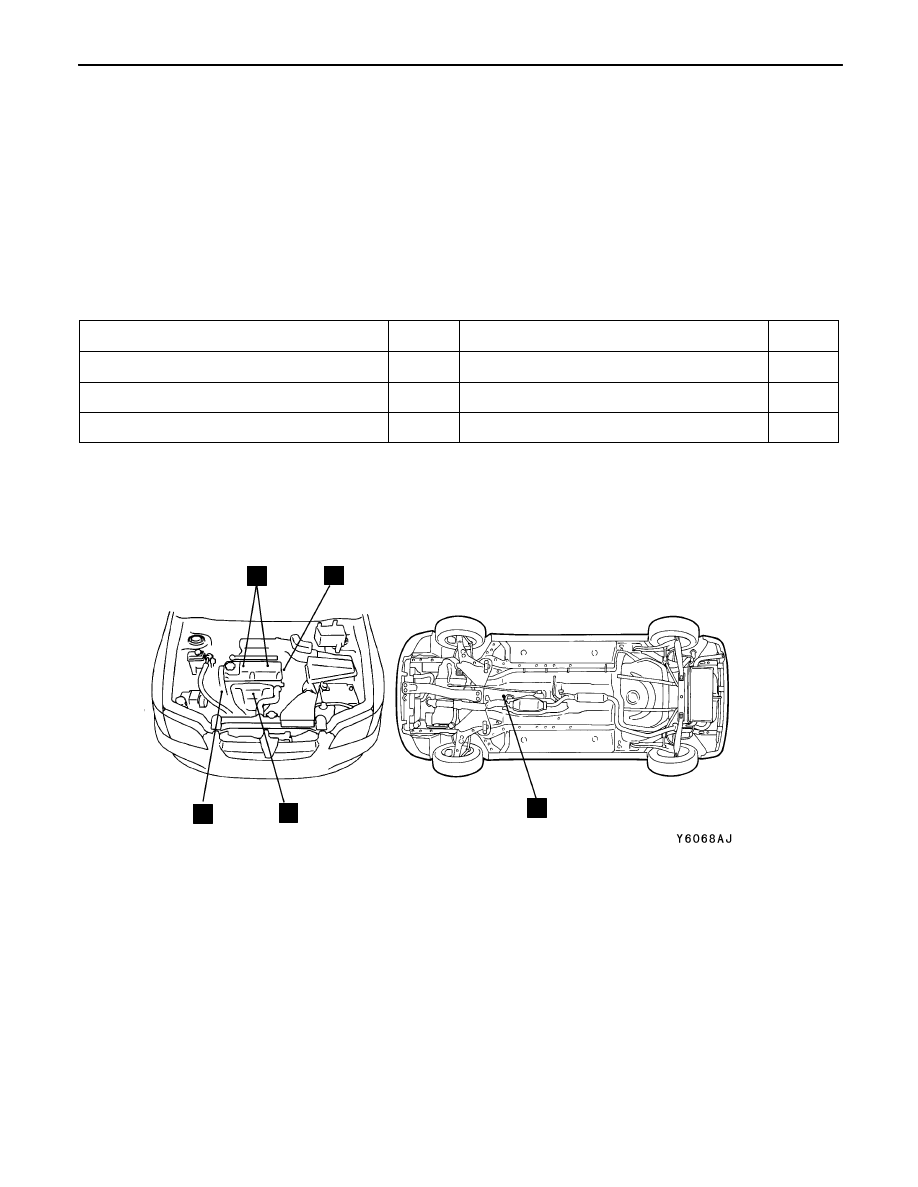

COMPONENT LOCATION

Name

Symbol

Name

Symbol

Camshaft position sensor

B

Ignition failure sensor

B

Crank angle sensor

C

Oxygen sensor (front)

D

Ignition coil

A

Oxygen sensor (rear)

E

C

B

A

D

E