Mitsubishi Space Star. Manual - part 3

General/Service Specifications/Sealants/Special Tools

ENGINE <4G9> –

11A-3

GENERAL

OUTLINE OF CHANGES

Since the resin intake manifold is adopted, the fuel system is changed, and the vehicle with A/T is added

to the lineup, the following service adjustment procedures are made.

Other service procedures are the same as before.

SERVICE SPECIFICATIONS

Items

Standard value

Limit

Idle speed r/min

A/T

650

±

100

–

Cylinder head bolt shank length mm

–

96.4

SEALANTS

Items

Specified sealants

Remarks

Beam camshaft cap and cylinder

head

3M ATD Part No.8660 or equivalent

Semi-drying sealant

Camshaft position sensor support

MITSUBISHI GENUINE PART

MD970389 or equivalent

Drive plate bolt

3M Stud locking 4170 or equivalent

–

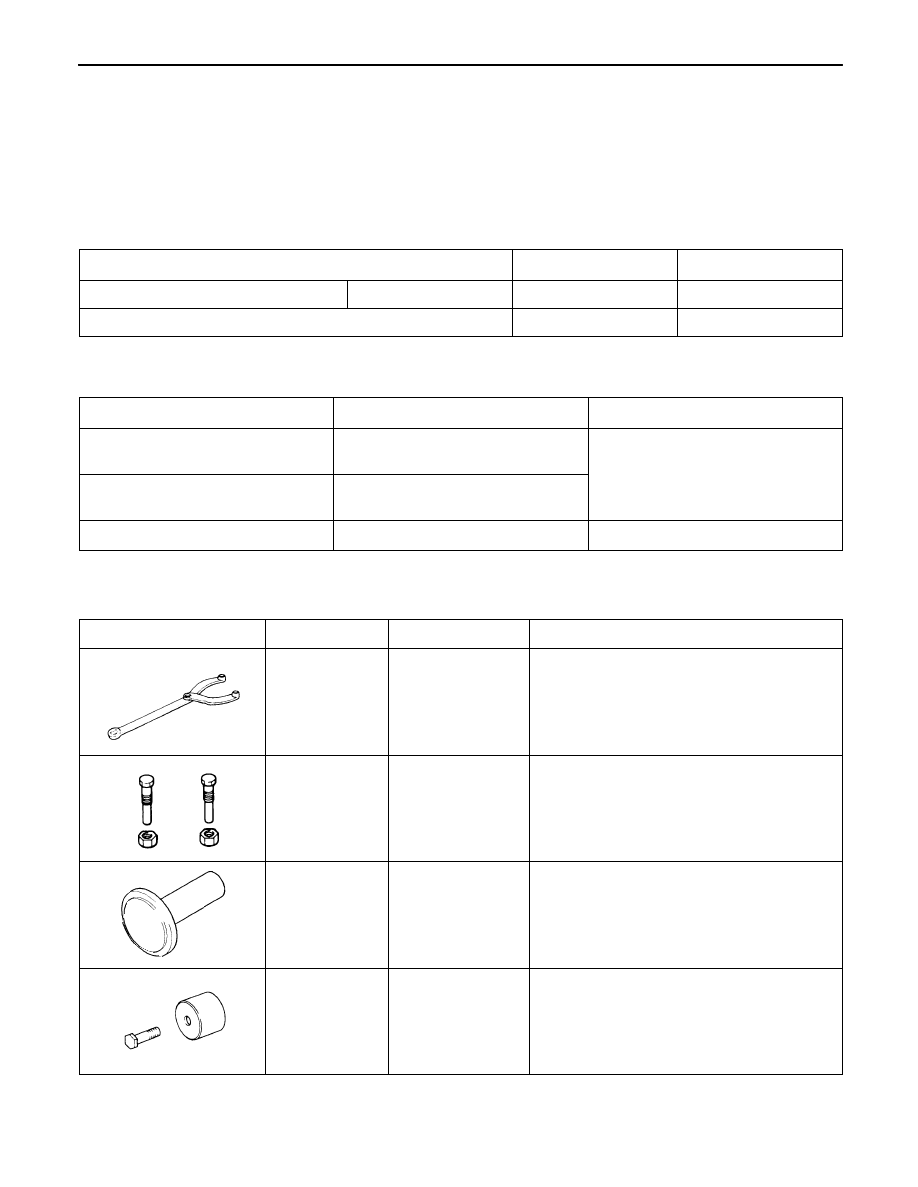

SPECIAL TOOLS

Tool

Number

Name

Use

MB990767

End yoke holder

Holding the camshaft sprocket

MD998719

Crankshaft pulley

holder pin

Holding the camshaft sprocket

MD998762

Circular packing

installer

Press-fitting the circular packing

MD998713

Camshaft oil seal

installer

Press-fitting the camshaft oil seal