Mitsubishi Lancer. Manual - part 196

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING

37-32

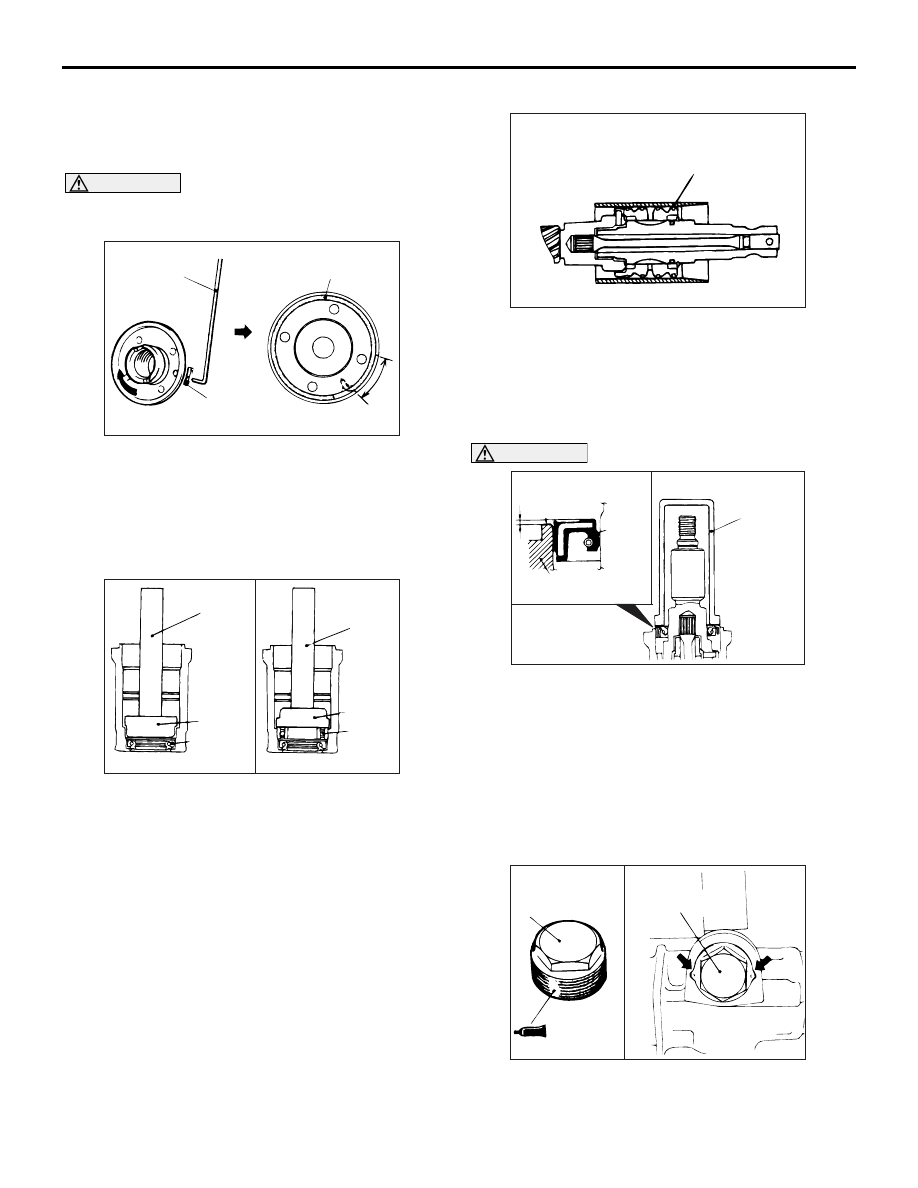

3. Wrap the rack end with plastic tape, and push the

rack bushing onto the rack.

>>E<< CIRCLIP INSTALLATION

CAUTION

Insert the circlip to the rack stopper hole while

turning the rack stopper clockwise.

ACX01158

Circlip

Slot

AB

Circlip

Slot

Insert the circlip to the rack stopper hole through cyl-

inder hole. Turn the rack stopper clockwise and

insert the circlip firmly.

>>F<< UPPER OIL SEAL/UPPER

BEARING INSTALLATION

ACX01159AC

MB990938

MB991203

Oil seal

MB991203

Bearing

MB990938

Apply a coating of ATF DEXRON III or DEXRON II to

the outside of the upper oil seal/upper bearing. Using

the following special tools, press the upper oil

seal/upper bearing into the valve housing.

• Bar (snap-in type) (MB990938)

• Oil seal and bearing Installer (MB991203)

>>G<< SEAL RINGS INSTALLATION

ACX01160 AB

MB991317

Because the seal rings expand after installation,

tighten after installing by using special tool seal ring

installer (MB991317) to compress the rings, or press

down by hand.

>>H<< LOWER OIL SEAL INSTALLATION

ACX01161

Housing

AC

Oil

seal

Approximately

1 mm

MB990941

CAUTION

To eliminate a seal malfunction at the valve hous-

ing alignment surface, the upper surface of the

oil seal should project outward approximately 1

mm from the housing edge surface.

Using special tool torque tube bearing installer

(MB990941), press the oil seal into the valve hous-

ing.

>>I<< END PLUG INSTALLATION

ACX01162 AB

End plug

End plug

1. Apply specified sealant to the threaded part of the

end plug.