Mitsubishi Lancer. Manual - part 61

PRECAUTIONS BEFORE SERVICE

GENERAL

0-4

SERVICING THE ELECTRICAL SYSTEM

M6001001000025

ACX00880AD

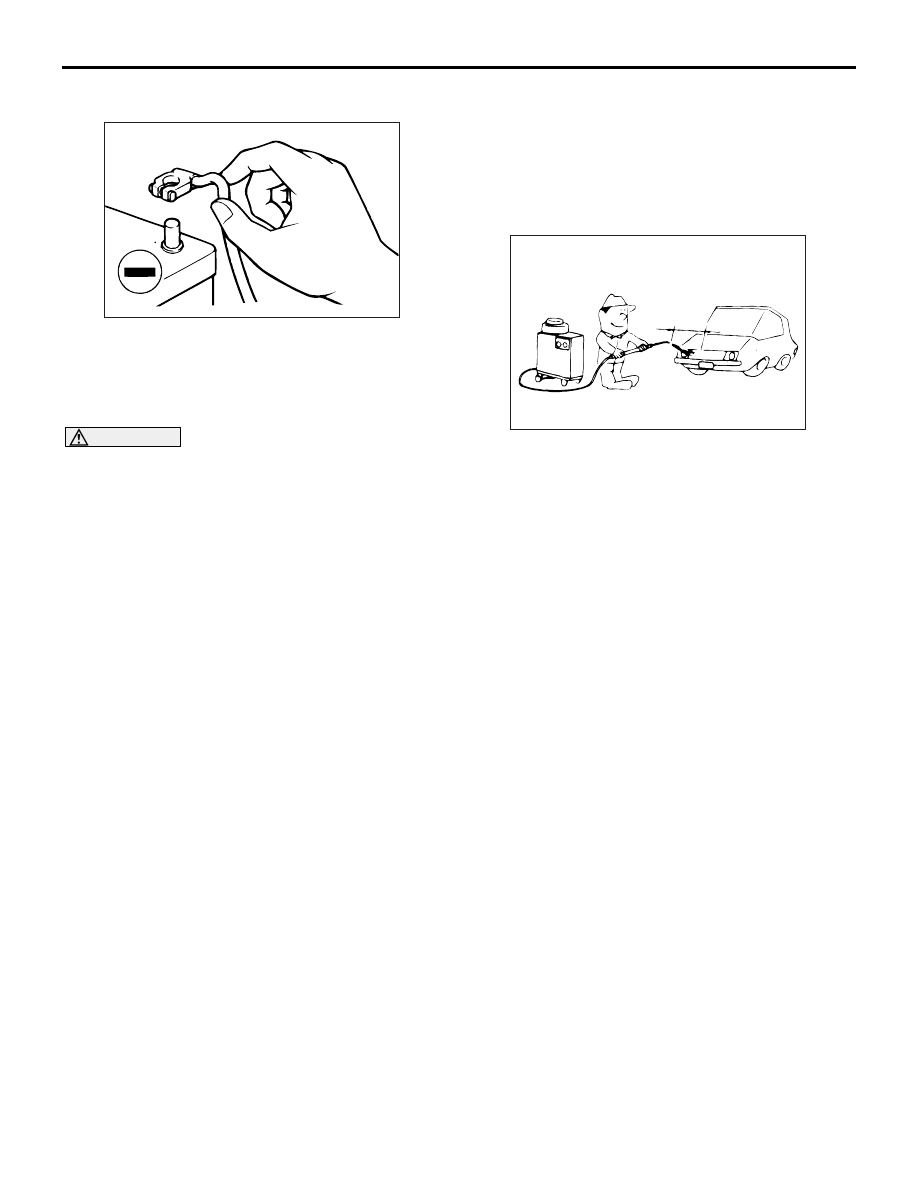

Before replacing a component related to the electri-

cal system and before undertaking any repair proce-

dures involving the electrical system, be sure to first

disconnect the negative (-) cable from the battery in

order to avoid damage caused by short-circuiting.

CAUTION

Before connecting or disconnecting the negative

(-) cable, be sure to turn off the ignition switch

and the lighting switch. (If this is not done, there

is the possibility of semiconductor parts being

damaged.)

APPLICATION OF ANTI-CORROSION

AGENTS AND UNDERCOATS

M6001001100022

If oil or grease gets onto the oxygen sensor, it will

cause a drop in the performance of the sensor.

Cover the oxygen sensor with a protective cover

when applying anti-corrosion agents and undercoats.

PRE-INSPECTION CONDITION

M6001001200029

"Pre-inspection condition" refers to the condition that

the vehicle must be in before proper engine inspec-

tion can be carried out. If you see the words "Set the

vehicle to the pre-inspection condition" in this man-

ual, it means to set the vehicle to the following condi-

tion.

• Engine coolant temperature: 80 to 90°C

• Lamps, electric cooling fan and all accessories:

OFF

• M/T: Neutral

• A/T: P range

VEHICLE WASHING

M6001001300037

ACX00881

Approx.

40 cm

AE

If high-pressure car-washing equipment or steam

car-washing equipment is used to wash the vehicle,

be sure to note the following information in order to

avoid damage to plastic components, etc.

• Spray nozzle distance: Approx. 40 cm or more

• Spray pressure: 3,900 kPa or less

• Spray temperature: 82°C or less

• Time of concentrated spray to one point: within

30 sec.

MULTI USE TESTER (M.U.T.-II/III) SUB

ASSEMBLY

M6001002000028

Refer to the "M.U.T.-II/III OPERATING INSTRUC-

TIONS" for instructions on handling the M.U.T.-II/III.