Mitsubishi Lancer. Manual - part 36

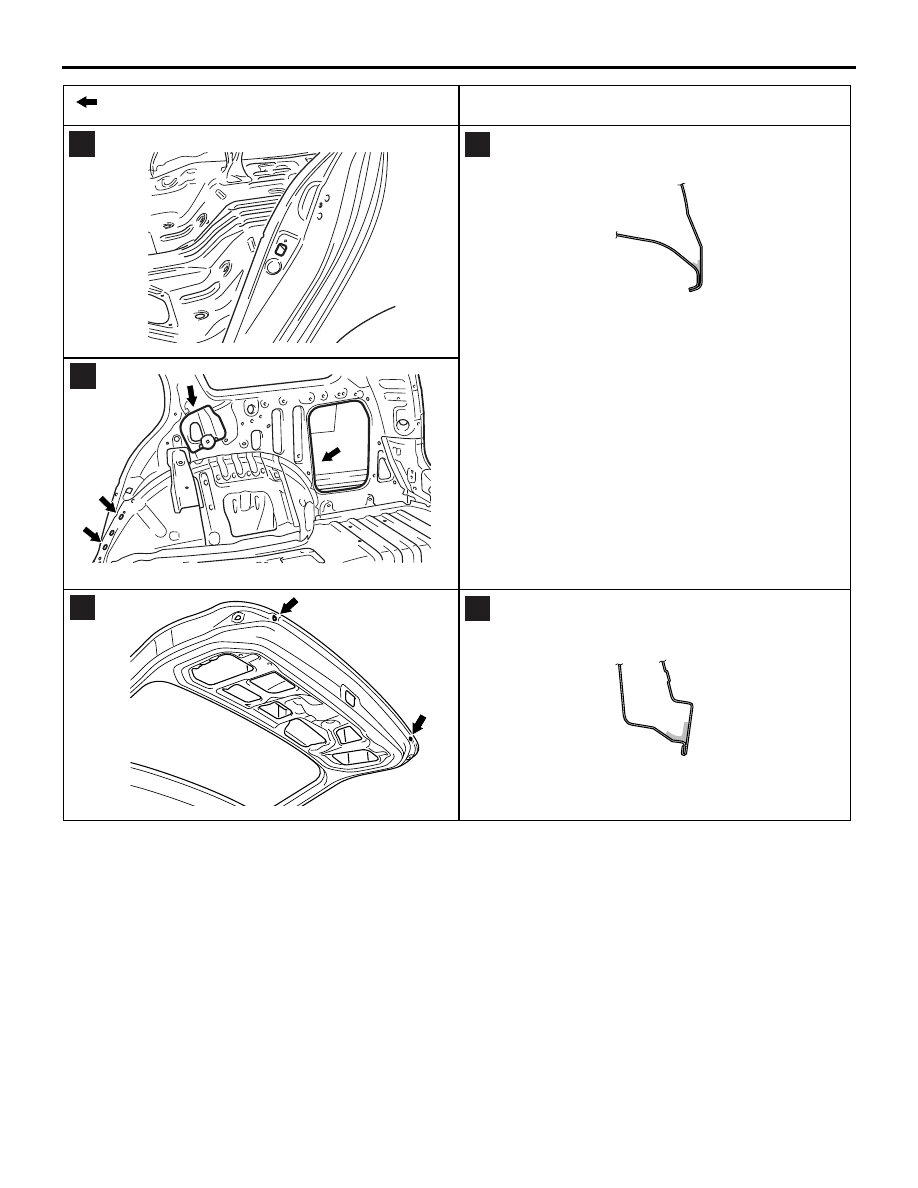

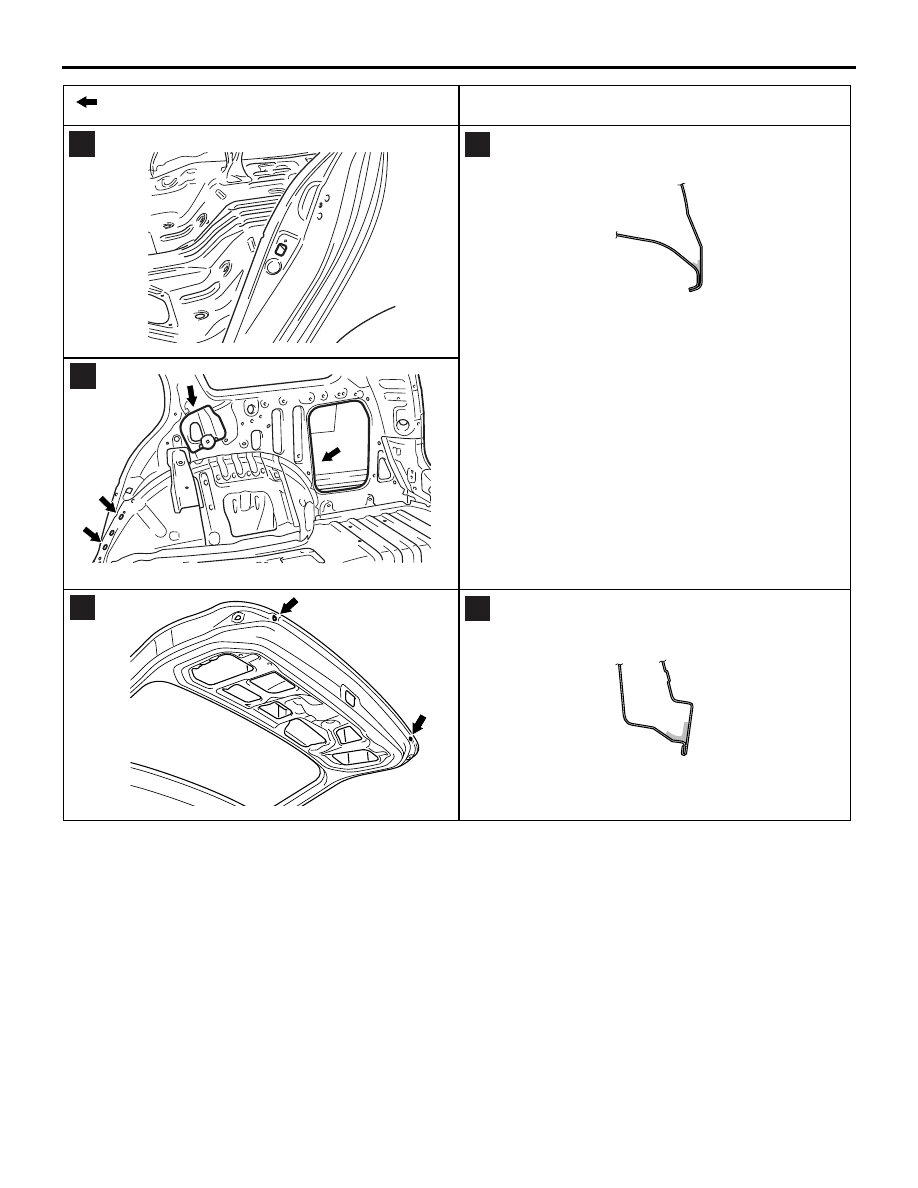

: Nozzle insertion openings

Application surfaces

AB300703AC

13

AB300915AB

H

AB301049 AB

14

AB300700

AB

15

AB300916

AB

I

WAX INJECTION LOCATIONS

CORROSION PROTECTION

4-14

|

|

|

: Nozzle insertion openings Application surfaces AB300703AC 13 AB300915AB H AB301049 AB 14 AB300700 AB 15 AB300916 AB I WAX INJECTION LOCATIONS CORROSION PROTECTION 4-14 |