Mitsubishi Lancer (4A9 engine). Manual - part 307

COMPRESSOR ASSEMBLY

HEATER, AIR CONDITIONER AND VENTILATION

55A-109

COMPRESSOR ASSEMBLY

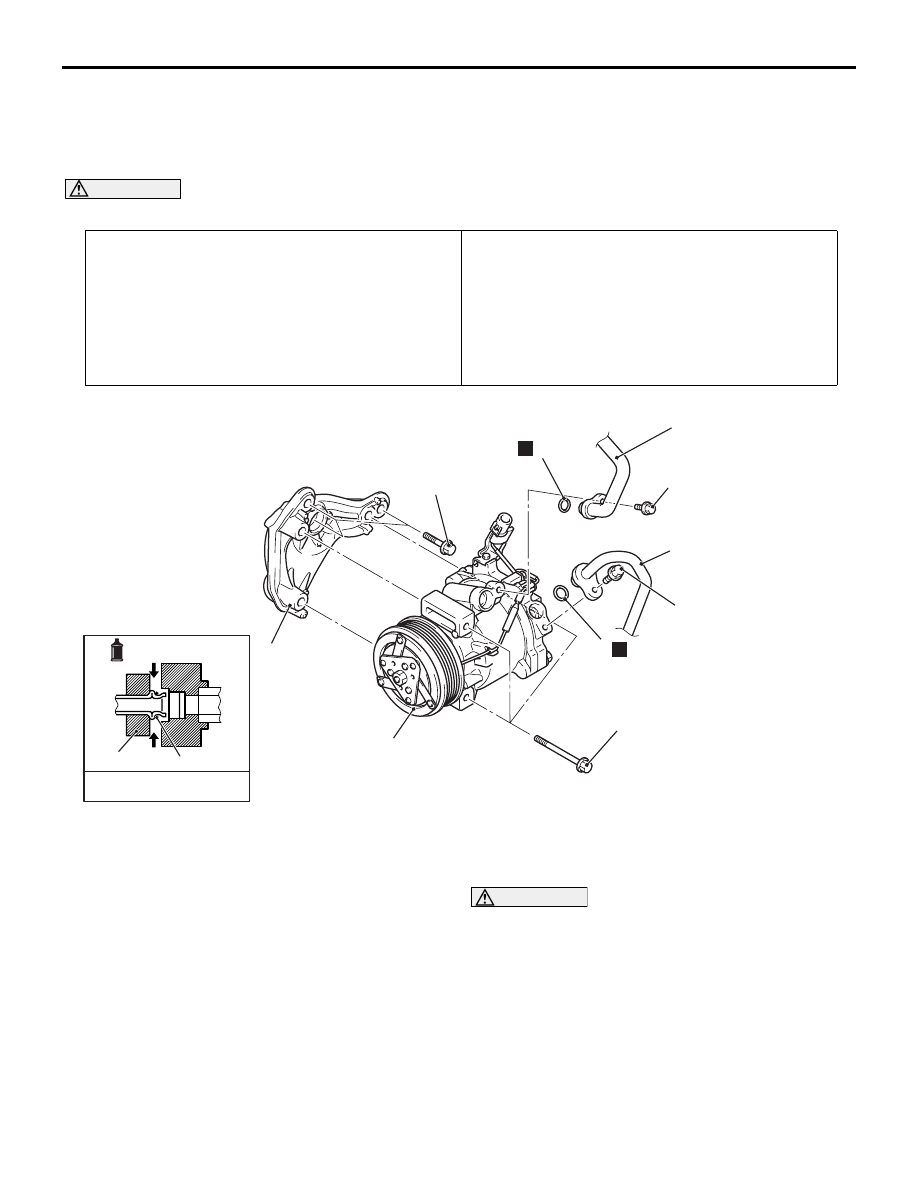

REMOVAL AND INSTALLATION <1600 (M/

T)>

M1552004403580

CAUTION

•

Pre-removal operation

• Discharging refrigerant (Refer to )

• Engine room under cover front A and B, Engine room side

cover removal (Refer to GROUP 51, Under Cover ).

• Drive belt removal (Refer to GROUP 11A Crankshaft Pul-

ley )

Post-installation Operation

• Drive belt installation (Refer to GROUP 11A Crankshaft

Pulley )

• Drive belt tension check and adjustment (Refer to

GROUP 11A

− Drive Belt Tension Check ). <Petrol

engine>

• Charging refrigerant (Refer to )

• Engine room under cover front A and B, Engine room side

cover installation (Refer to GROUP 51, Under Cover ).

ACB01639

1, 2

3

5

3

1

2

4

AB

3

N

N

10 ± 2 N·m

10 ± 2 N·m

23 ± 6 N·m

A/C compressor oil:

SUN PAG 56 or S10X

-Pipe coupling

23 ± 6 N·m

Removal steps

<<

A

>>

1.

Discharge flexible hose connection

<<

A

>>

2.

Suction flexible hose connection

3.

O-ring

<<

B

>>

>>

A

<<

4.

A/C compressor and clutch

assembly

5.

A/C compressor bracket

When removing the compressor, be careful not to subject the pulley and the clutch to impact.

NOTE: The service points which are not described

are the same as before.

REMOVAL SERVICE POINTS

<<A>> DISCHARGE FLEXIBLE HOSE/SUCTION

FLEXIBLE HOSE DISCONNECTION

CAUTION

Use the plug which is not breathable because A/

C compressor oil or receiver have high hygro-

scopicity.

Plug the hose nipple removed to prevent the entry of

dust and dirt.

<<B>> A/C COMPRESSOR AND CLUTCH

ASSEMBLY REMOVAL

Be careful not to spill the A/C compressor oil and

remove the A/C compressor.